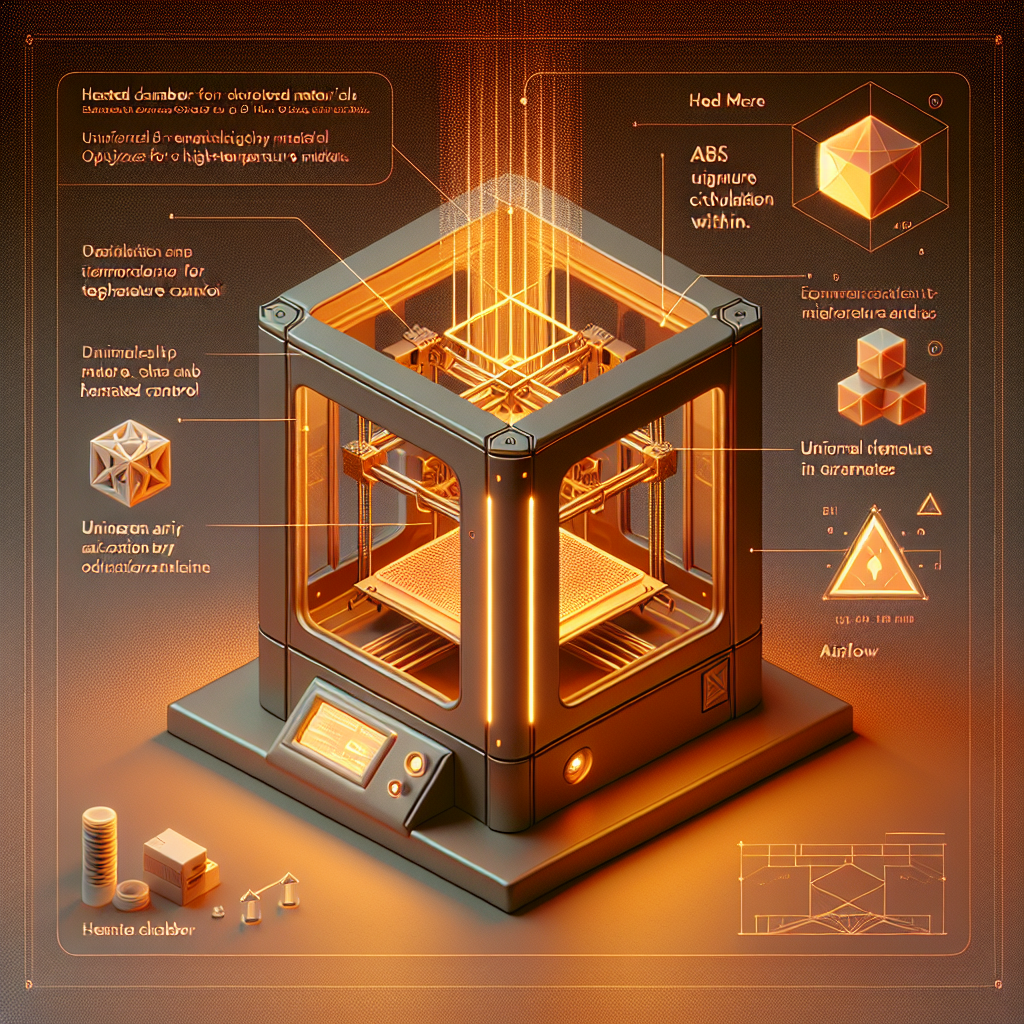

Understanding the Importance of a Heated Chamber

When it comes to high-temperature 3D printing, a heated chamber is not just a luxury—it’s a necessity. Materials like ABS, Polycarbonate (PC), Nylon, PEI (Ultem), and PEEK require tightly controlled ambient temperatures to reach their full mechanical potential and maintain dimensional accuracy. A heated chamber ensures the print environment remains at a stable, elevated temperature throughout the printing process, minimizing warping, cracking, and layer separation.

Why You Need a Heated Chamber for High-Temperature Materials

High-performance thermoplastics demand high extrusion temperatures—often 250°C to 450°C. However, the surrounding environment matters just as much. If the chamber is too cold, the printed layers cool unevenly, causing internal stress and warping. A properly heated chamber keeps the part and the print bed at optimal temperatures, enabling consistent layer adhesion and superior surface finish.

Setting Up Your Heated Chamber

- Printer Compatibility: Not all 3D printers support a heated chamber. Ensure your machine is designed for or can be safely enclosed and heated. Consider thermal insulation and electrical safety.

- Temperature Control: High-temp chambers typically operate between 50°C and 130°C, depending on the material. Use accurate sensors and thermostatic controls to avoid overshooting and damaging electronics or mechanics.

- Air Circulation: Circulate hot air evenly with fans rated for high temperatures. Stagnant air can create uneven heating and poor print quality.

- Electronics Safety: Isolate controllers, stepper drivers, and other components outside of the heated chamber, or provide active cooling for those that must remain inside.

Material-Specific Chamber Temperatures

- ABS: 60°C – 80°C

- Polycarbonate (PC): 80°C – 110°C

- Nylon: 50°C – 80°C

- PEI (Ultem): 120°C – 150°C

- PEEK: 120°C – 150°C

Always consult your filament manufacturer for recommended chamber and extrusion temperatures.

Best Practices for High-Temperature Printing

- Pre-Heat the Chamber: Allow the chamber to reach the target temperature before starting the print. This pre-conditioning prevents initial layer warping.

- Monitor Humidity: High-temp materials are often hygroscopic. Keep humidity low by using filament dryers and desiccant packs inside the enclosure.

- Ventilation: Printing at high temperatures can release fumes. Use a proper ventilation system or HEPA/carbon filtration.

- Post-Print Cooling: Avoid opening the chamber immediately after printing. Let the part and chamber cool down gradually to minimize thermal shock and cracking.

Troubleshooting Common Issues

- Warping: Increase chamber temperature or improve airflow for better uniformity.

- Electronics Overheating: Install heat shields or relocate electronics outside the hot zone.

- Stringing or Oozing: Adjust retraction settings and verify that your hotend is not overheating due to the elevated chamber ambient temperature.

Conclusion

Using a heated chamber unlocks the true potential of high-performance 3D printing materials. By carefully controlling ambient temperature and following best practices, you’ll achieve stronger, more reliable, and dimensionally accurate prints. Whether you’re prototyping for aerospace, automotive, or industrial applications, mastering the heated chamber is a key skill for serious 3D printing enthusiasts and professionals alike.

Leave a Reply