Understanding Carbon Fiber Filament

Carbon fiber filament is a composite material made by infusing short carbon fibers into a base thermoplastic, commonly PLA, PETG, or Nylon. The result is a filament that boasts significantly improved strength, stiffness, and dimensional stability compared to its base polymer. However, printing with carbon fiber filament comes with specific requirements and best practices to achieve optimal results and to avoid common pitfalls.

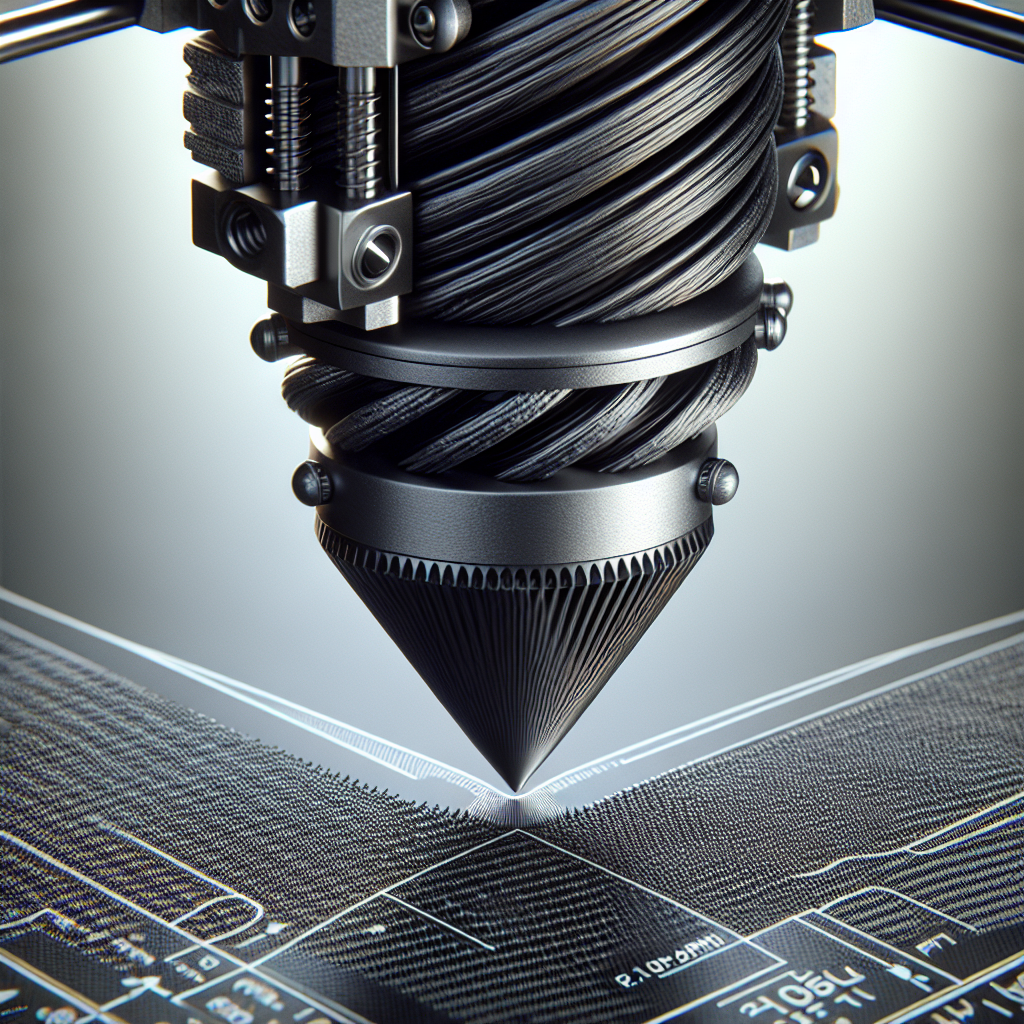

Choosing the Right Printer and Hardware

Not all 3D printers are equipped to handle carbon fiber filament. The abrasive nature of carbon fibers can quickly wear out standard brass nozzles and even damage soft parts of your extruder. For best results:

- Nozzle Material: Use a hardened steel or ruby-tipped nozzle. Brass nozzles will degrade rapidly, leading to inconsistent prints.

- Nozzle Size: At least 0.4 mm, though 0.5 mm or larger is preferred to reduce the risk of clogs from the chopped fibers.

- Extruder: A direct drive extruder is often more reliable, especially when printing with flexible carbon fiber filament blends.

Optimizing Print Settings

Each carbon fiber filament brand and base material will have slightly different optimal settings, so always start with the manufacturer’s recommendations. Here are key parameters to adjust:

- Temperature: Carbon fiber PLA generally prints at 200–230°C, PETG at 230–250°C, and Nylon at 250–280°C. The added fibers can increase the required nozzle temperature.

- Bed Temperature: PLA-based filaments may not require a heated bed, but PETG and Nylon blends print best with 60–90°C to prevent warping.

- Print Speed: Slow down to 30–60 mm/s. The added fibers increase viscosity and can cause jams at higher speeds.

- Retraction: Carbon fiber increases filament stiffness, so reduce retraction distance to minimize clogging or jams.

- Layer Height: Use a layer height of at least 0.2 mm to avoid trapping fibers and ensure smooth extrusion.

Bed Adhesion and Warping

Some carbon fiber filaments, especially those based on Nylon or PETG, have a tendency to warp. For best adhesion:

- Apply a suitable adhesive such as a glue stick, PEI sheet, or Magigoo to your build plate.

- If using Nylon-based carbon fiber, consider a Garolite (G10/FR4) print bed.

- Use a brim or raft if the part’s footprint is small or has sharp corners.

Filament Storage and Handling

Carbon fiber filaments, especially those with a Nylon base, are highly hygroscopic and will absorb moisture from the air. Moist filament will result in poor print quality and weak parts. Always store your filament in a dry box or use desiccant packs, and dry the filament at 70–80°C for 4–6 hours if moisture is suspected.

Design Tips for Extra Strength

While carbon fiber filament adds significant rigidity, the orientation and design of your parts matter:

- Print Orientation: FDM parts are weakest along the layer lines (Z-axis). Orient your part so critical stress points align with the X-Y plane for maximum strength.

- Wall Thickness: Increase wall/perimeter count to at least 3–4 to maximize the benefit of the carbon fibers.

- Infill Density and Pattern: Use higher infill densities (>=40%) with grid or gyroid patterns for robust, functional parts.

- Filament Choice: For the strongest parts, choose carbon fiber reinforced Nylon, but be prepared for extra attention to bed adhesion and drying.

Post-Processing and Finishing

Carbon fiber reinforced prints have a matte, slightly textured finish and are generally easy to sand or machine. However, the fibers can create a rough edge when cut; wear a mask when sanding to avoid inhaling fine particles, and use sharp tools for drilling or trimming.

Common Issues and Troubleshooting

- Nozzle Clogs: Use the correct nozzle size and routinely check for buildup. Cold pulls can help clear obstructions.

- Poor Layer Adhesion: Increase print temperature slightly and ensure filament is dry.

- Excessive Stringing: Lower print temperature and adjust retraction settings.

- Under-extrusion: Reduce print speed, ensure extruder gears are clean, and inspect for filament kinks.

Conclusion

Printing with carbon fiber filament opens up a world of possibilities for producing lightweight, strong, and dimensionally stable parts. With the right printer setup, careful filament handling, and dialed-in print settings, you’ll be able to make high-performance components that stand up to demanding applications. Always follow safety precautions when handling these materials and enjoy the leap in performance carbon fiber brings to your 3D printing projects!

Leave a Reply