Introduction to ABS Printing Challenges

Printing with ABS (Acrylonitrile Butadiene Styrene) filament offers durability, impact resistance, and the capability to withstand higher temperatures compared to popular filaments such as PLA. However, one common issue encountered when printing with ABS is warping—an unpleasant and frustrating experience familiar to many 3D printer users. Warping occurs when the printed object shrinks unevenly during cooling, causing the corners and edges to detach from the build plate and curl upward.

Fortunately, warping can be minimized or even completely eliminated by following best practices specific to ABS printing. This article will guide you through essential tips and proven techniques to ensure your ABS 3D prints come out perfectly flat and adhere strongly to the print bed.

Why Does ABS Warp?

ABS is highly susceptible to warping due to its high thermal expansion coefficient. It expands slightly when heated and shrinks as it cools. When the bottom layers of an ABS print cool faster than the upper layers, internal stresses accumulate, leading to the corners of the object peeling off the print bed. Managing temperature differences and proper bed adhesion are therefore essential for reliable ABS printing.

Essential Tips to Prevent ABS Warping

1. Maintain Proper Heated Bed Temperature

A heated bed is critical when printing with ABS filament. Keep the bed temperature between 95–110°C to reduce the thermal gradient between the first layer and subsequent layers. This steady temperature helps to prevent rapid cooling and shrinkage, significantly reducing the likelihood of warping.

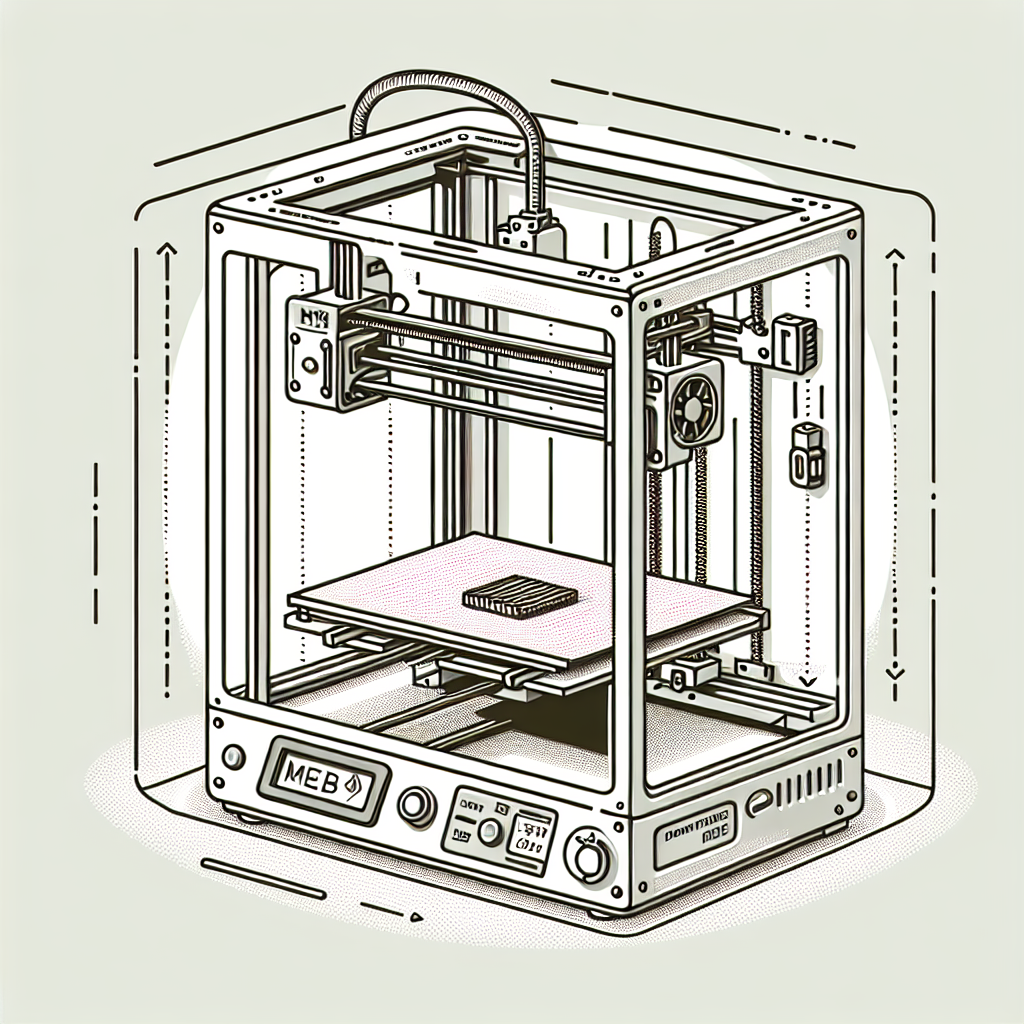

2. Enclose Your Printer to Control Ambient Temperature

Enclosing your 3D printer creates a stable printing environment, minimizing temperature fluctuations caused by drafts or room temperature variations. An enclosure maintains higher ambient temperatures and slows down cooling, resulting in uniform thermal shrinkage and improved ABS print outcomes.

3. Use Proper Bed Adhesion Techniques

Achieving good adhesion between ABS filament and the print bed is integral for warp-free prints. Consider the following methods to enhance bed adhesion:

- ABS Slurry: A mixture of ABS filament dissolved in acetone creates a strong bonding layer on the print bed.

- Kapton Tape: This heat-resistant adhesive tape provides excellent adhesion with ABS filament.

- BuildTak or PEI Adhesive Sheets: These specialty adhesive sheets provide reliable and consistent adhesion without mess.

- Glue Stick or Hair Spray: Common household alternatives that can also greatly enhance bed adhesion.

4. Optimize First Layer Settings

Ensuring your print’s first layer adheres properly to the bed is critical. Adjusting your printer settings can dramatically improve adhesion:

- Lower print speed: Slow the first layer down to 20–40 mm/s to ensure reliable adhesion.

- Increase extrusion width and layer height: Slightly increasing the initial layer thickness and width improves the contact surface area, enhancing bed adhesion.

- Adjust nozzle-bed gap correctly: Proper bed leveling and nozzle height calibration are essential to ensure a perfect first layer.

5. Disable Cooling Fans for Initial Layers

ABS is sensitive to rapid cooling. Turn off the cooling fans during the first few layers to maintain a steady temperature gradient. Gradually introduce cooling at later layers only if required to improve bridging or intricate detailing.

6. Consider Brims and Rafts

Adding a brim or a raft feature in your slicing software significantly enhances surface adhesion. A brim improves the initial layer adhesion by adding a thin perimeter around your print, while a raft creates a base platform onto which your print adheres, distributing stress evenly and reducing the likelihood of warping.

7. Keep Your ABS Filament Dry

ABS filament can absorb moisture from the environment, degrading print quality and layer adhesion. Store ABS filament in a moisture-free, airtight container to prevent humidity issues that contribute to warping.

Troubleshooting Common Issues

- Warped corners: Adjust bed temperature, enclosure settings, or use adhesive agents as mentioned above.

- Weak layer adhesion: Raise extrusion temperature slightly (230–250°C) and slow down print speed.

- Splitting layers: Increase enclosure temperature, disable cooling fans, or print at slower speeds to improve layer bonding.

Conclusion

Successfully printing with ABS filament without warping requires understanding the unique challenges presented by ABS material properties and applying specialized techniques to mitigate temperature fluctuations and ensure sufficient bed adhesion. By following the tips outlined in this guide, you can dramatically enhance the performance and reliability of your ABS 3D prints. Keep experimenting, fine-tune your printer settings, and soon you’ll master ABS printing—with consistently strong, accurate, and warp-free results.

Leave a Reply