Introduction to Printing Large 3D Models Successfully

Printing large 3D models can be incredibly exciting and rewarding, but it presents unique challenges—namely warping and cracking. Warping occurs due to uneven cooling, causing the corners of your print to curl upwards and detach from the build platform. Cracking, conversely, happens when the layers separate during the printing process due to factors such as inconsistent temperatures or inadequate adhesion between layers. Fortunately, with the right techniques and tools, you can significantly reduce or even completely eliminate these issues.

In this comprehensive guide, we’ll explore proven methods and expert tips to help you effortlessly produce large 3D prints without warping or layer separation.

Understanding Warping and Cracking in 3D Prints

To effectively prevent these issues, it helps first to understand why they occur:

- Warping: As the filament cools after extrusion, it shrinks slightly. When this shrinkage isn’t uniform across the printed object, it creates internal stresses that pull the edges upward, causing warping.

- Cracking (Layer Separation): Similar temperature-related stresses can also lead to layer adhesion weakness. If layers cool too quickly or inconsistently, they may fail to bond properly, causing cracks and separations.

Preventing these common problems involves a combination of effective temperature management, proper print settings, and optimized environmental conditions.

Use a Heated Build Plate

A heated print bed is essential for large prints. Keeping your build platform warm ensures that your first layer adheres properly, reducing the risk of warping significantly. Generally, for materials such as ABS or Nylon, a heated bed temperature of around 100-110°C is ideal, while PLA and PETG typically require temperatures around 50-70°C.

Optimize Print Bed Adhesion

Ensuring strong, consistent bed adhesion is crucial for successful large prints. Here are several proven techniques:

- Adhesive Substances: Use adhesion aids such as glue sticks, hairspray, or specialized bed adhesive solutions to enhance initial layer bonding.

- Build Surface Materials: Consider specialized print surfaces such as PEI sheets, BuildTak, or Glass with adhesive additives for reliable adherence.

- Rafts and Brims: Employing rafts or brims increases the surface area on the print bed, distributing stress more evenly and preventing edges from lifting.

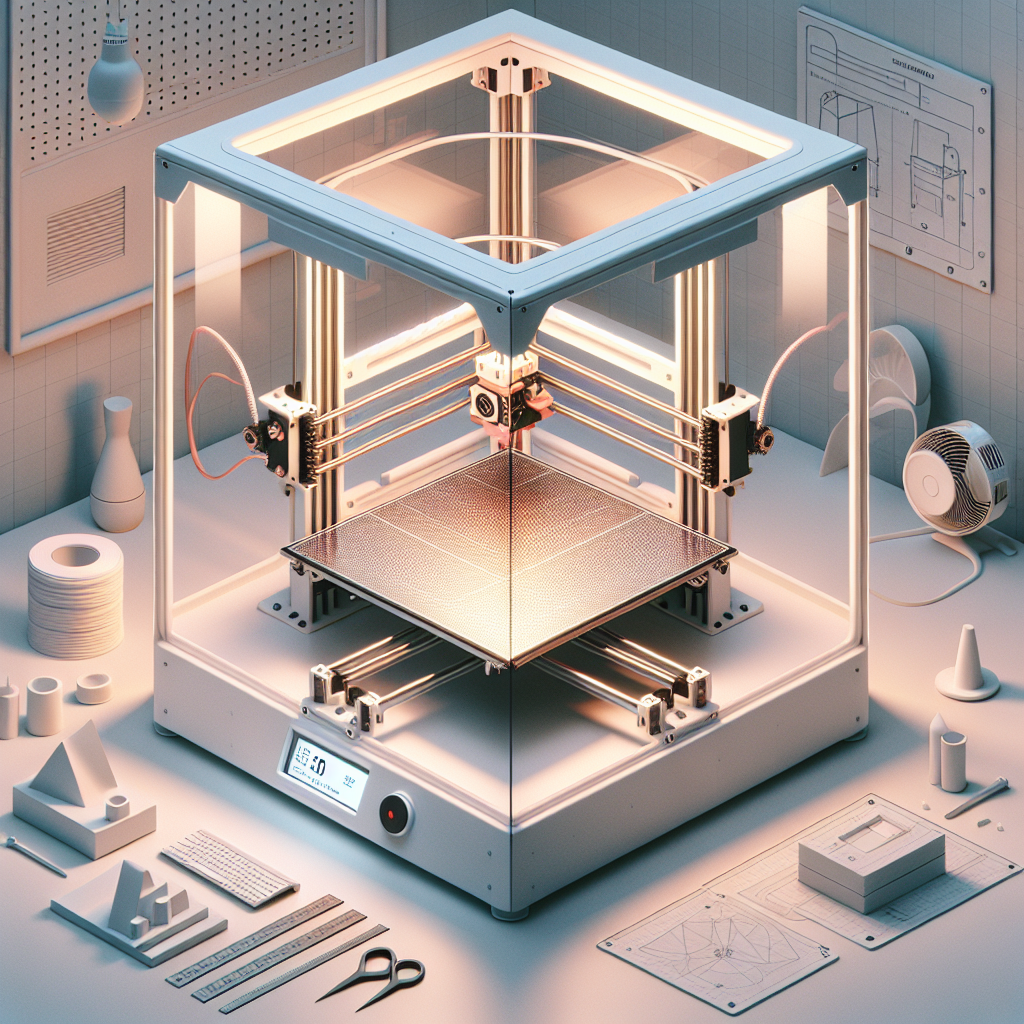

Control Your Printing Environment

3D printing large models requires maintaining consistent environmental conditions to minimize uneven cooling. Temperature fluctuations and drafts can cause warping and cracking, so consider the following recommendations:

- Enclosed Build Chambers: An enclosure around your printer keeps ambient temperatures stable, reducing drafts and thermal shock. It’s particularly critical when printing with materials prone to warping (ABS, Nylon, and high-temperature filaments).

- Draft Prevention: Avoid placing your printer in areas with direct airflow from air conditioning, fans, or open windows.

Adjust Your Print Settings

Fine-tuning your print settings can help reduce stress and improve inter-layer adhesion:

- Layer Height: Increase your layer height slightly to minimize the number of layers, thereby reducing internal stresses within your model.

- Printing Speed: Lower your printing speed to allow each layer ample time to adhere properly before cooling occurs.

- Infill and Shell Thickness: Adjust your infill and shells to balance structural integrity and stress. Lower infill percentages paired with thicker shells can reduce internal tension and warping.

Use Filament Cooling Wisely

Cooling fans help solidify the filament rapidly and enhance print detail. However, they can also cause rapid cooling and warping, especially with large models. Here’s how to manage cooling effectively:

- ABS and Nylon: Generally, turn off or significantly reduce cooling fan speed to avoid warping.

- PLA and PETG: Use moderate cooling to enhance detail while avoiding excessive cooling that leads to cracks or separation.

Filament Selection for Large Prints

Selecting the right filament material can significantly impact your final print quality:

- PLA: Easy to print and less prone to warping, ideal for beginners and large prints with less structural stress.

- PETG: Offers good balance between ease of printing and strength, with moderate warping resistance.

- ABS and Nylon: Require controlled environments and heated enclosures for best results, but provide superior durability and heat resistance.

Utilize Advanced Techniques: Dynamic Layer Temperatures and Heated Chambers

For professional-grade large models, consider advanced solutions:

- Dynamic Temperature Control: Adjust nozzle and bed temperatures gradually throughout the print to reduce thermal stress.

- Heated Chambers: Professional-grade printers with temperature-controlled enclosures maintain stable thermal conditions for minimal warping and cracking.

Conclusion: Achieve Large 3D Prints with Confidence

Warping and cracking need not discourage your ambitions to print large-scale 3D models. By understanding their root causes and carefully implementing these preventive measures—heated build plates, optimized adhesion, environmental control, appropriate print settings, and thoughtful filament selection—you’ll be well on your way to creating impressive, large-scale prints successfully and reliably.

Leave a Reply