Introduction

Achieving a smooth, professional finish on 3D prints is a goal shared by hobbyists and professionals alike. While sanding is a tried-and-true method, it’s time-consuming and can be messy, especially with intricate or delicate prints. Luckily, there are several effective techniques to obtain a polished look without ever picking up a piece of sandpaper. In this article, I’ll draw on years of hands-on experience to guide you through the best methods for getting a smooth finish on your 3D prints—no sanding required.

1. Fine-Tuning Your Print Settings

The smoothness of your final print often starts in your slicer. Here’s how to optimize your settings:

- Layer Height: Use the smallest layer height your printer and filament can reliably manage. A 0.1mm layer height reduces visible layer lines significantly.

- Print Speed: Lower print speeds (30-40mm/s) typically result in more accurate extrusion and smoother surfaces.

- Extrusion Width and Flow: Calibrate your extrusion multiplier/flow rate to avoid over-extrusion, which can cause roughness.

- Enable ‘Ironing’: Most slicers have an “ironing” feature that smooths the topmost layer by moving the hot nozzle over it without extruding more plastic.

Slicer optimization minimizes the need for post-processing and can make your prints look as if they’ve already been finished.

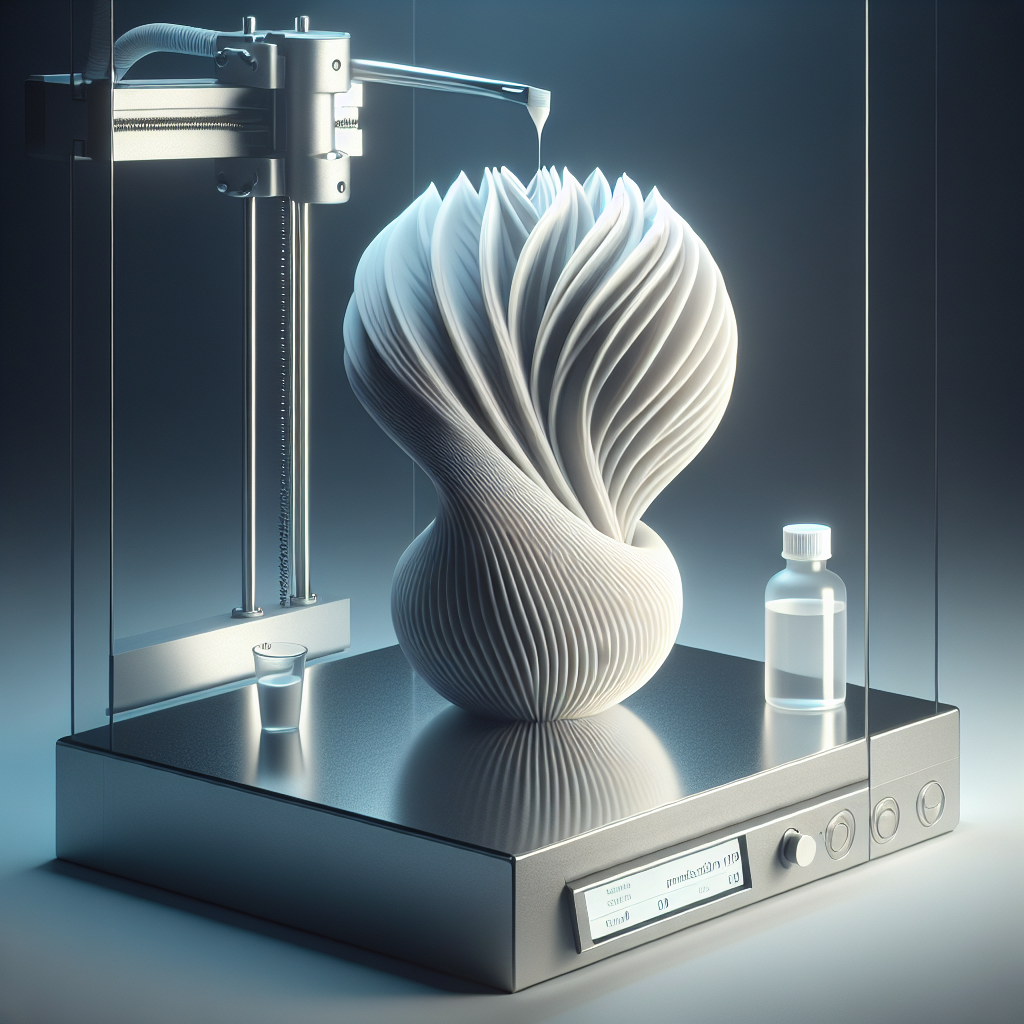

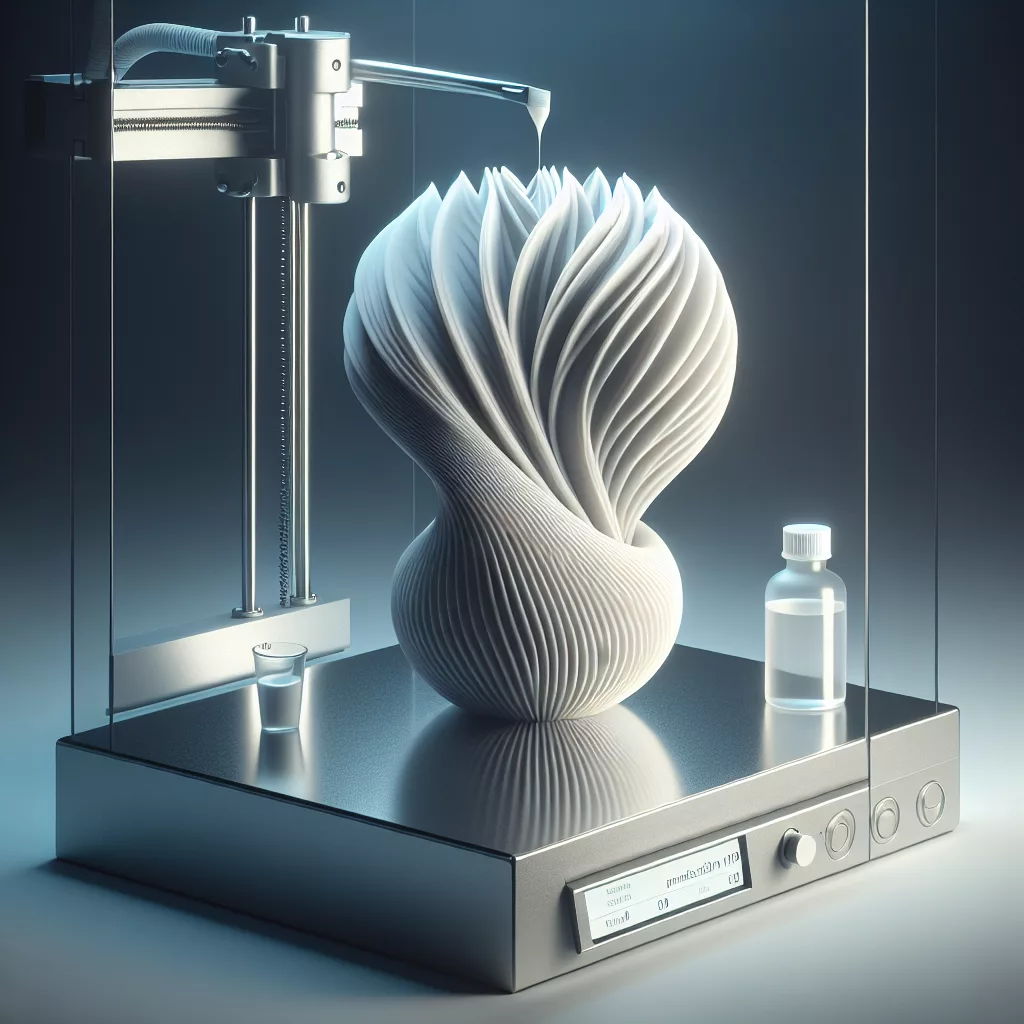

2. Chemical Smoothing Techniques

Depending on your filament type, chemical smoothing is a powerful, hands-off way to achieve glossy, smooth surfaces.

For ABS: Acetone Vapor Smoothing

Acetone vapor weakens the surface of ABS prints, allowing the plastic to flow slightly and fill in layer lines.

- Place your print in a well-ventilated enclosure (a glass or metal container).

- Add a small amount of acetone into the container (never directly on the print).

- Let the vapors interact with the print for 10-20 minutes, checking regularly.

- Remove and let the print dry completely in fresh air.

Safety note: Acetone is highly flammable—always use chemical smoothing outdoors or in a ventilated area and away from ignition sources.

For PLA: Specialized Solvents

PLA is more challenging to chemically smooth. However, products like THF (tetrahydrofuran) or specialty smoothing solutions such as PolyMaker PolySmooth combined with their Polysher machine can work. These methods are less common, but worth exploring if you regularly print with PLA.

3. Use the Right Filament

Some filaments are engineered for smoother finishes out-of-the-box. For instance, Silk PLA and “Glossy” PLA blends contain additives that create a shiny, smooth appearance straight from the print bed. These filaments can make layer lines less pronounced and give your prints a high-end look without any post-processing.

4. Post-Processing With Fillers and Coatings

If you want to avoid sanding but still want a truly polished finish, surface coatings are your friend:

- Epoxy Resin: Brush or pour clear epoxy resin over your print. It self-levels, hiding layer lines and creating a durable, glassy finish.

- Spray Paint Primers: High-build automotive primers spray on and fill in minor imperfections.

- Shellac and Varnish: For decorative prints, clear shellac or acrylic varnish can smooth and protect surfaces.

Always allow coatings to cure fully before handling your prints.

5. Optimize Your Cooling and Retraction

Poor cooling or stringing can add roughness to your print’s surface. Use adequate part cooling fans and fine-tune your retraction settings to reduce blobs and strings, resulting in a much smoother finish straight from the printer.

Conclusion

Getting a smooth finish on 3D prints without sanding is not only possible—it’s often preferable, especially for complex or fragile models. By optimizing slicer settings, using chemical smoothing (where appropriate), selecting the right filament, applying surface coatings, and dialing in your printer’s cooling and retraction, you can elevate your prints to a professional level without the dust and hassle of sanding. Experiment with these methods to find the combination that works best for your setup, and enjoy smoother, more beautiful 3D prints.

Leave a Reply