The Birth of 3D Printing: The 1980s Era

In the early 1980s, the concept of 3D printing was revolutionary yet largely theoretical. The groundbreaking moment came in 1984 when Chuck Hull invented stereolithography (SLA), marking the true birth of additive manufacturing. Hull, who later founded 3D Systems, patented SLA technology in 1986. Initially, SLA involved using ultraviolet lasers to solidify liquid photopolymers layer-by-layer, enabling intricate model creation and prototyping with unprecedented precision.

Early Commercialization and Industrial Adoption: 1990s

Throughout the 1990s, 3D printing transitioned from innovative laboratory technology to practical industrial application. Selective Laser Sintering (SLS), invented by Carl Deckard, emerged during this period, allowing the use of powder-based printing materials. Simultaneously, Scott Crump invented Fused Deposition Modeling (FDM), a technique that extrudes thermoplastic filaments layer-by-layer. Both SLS and FDM innovations significantly expanded the capabilities of 3D printing, opening the door for broader industrial adoption and rapid prototyping in automotive, aerospace, and medical fields.

Expanding Accessibility: The 2000s

As we progressed into the 2000s, 3D printing technologies became increasingly accessible beyond industrial manufacturing. Patents began to expire around key technologies such as FDM, enabling a surge of affordable, desktop 3D printers. Companies and organizations, most notably RepRap and MakerBot, drove innovation by creating open-source designs, significantly lowering entry barriers for hobbyists, educators, and small businesses. The democratization of 3D printing technology meant that enthusiasts and small entrepreneurs could now experiment, innovate, and bring ideas to life in their homes and workshops.

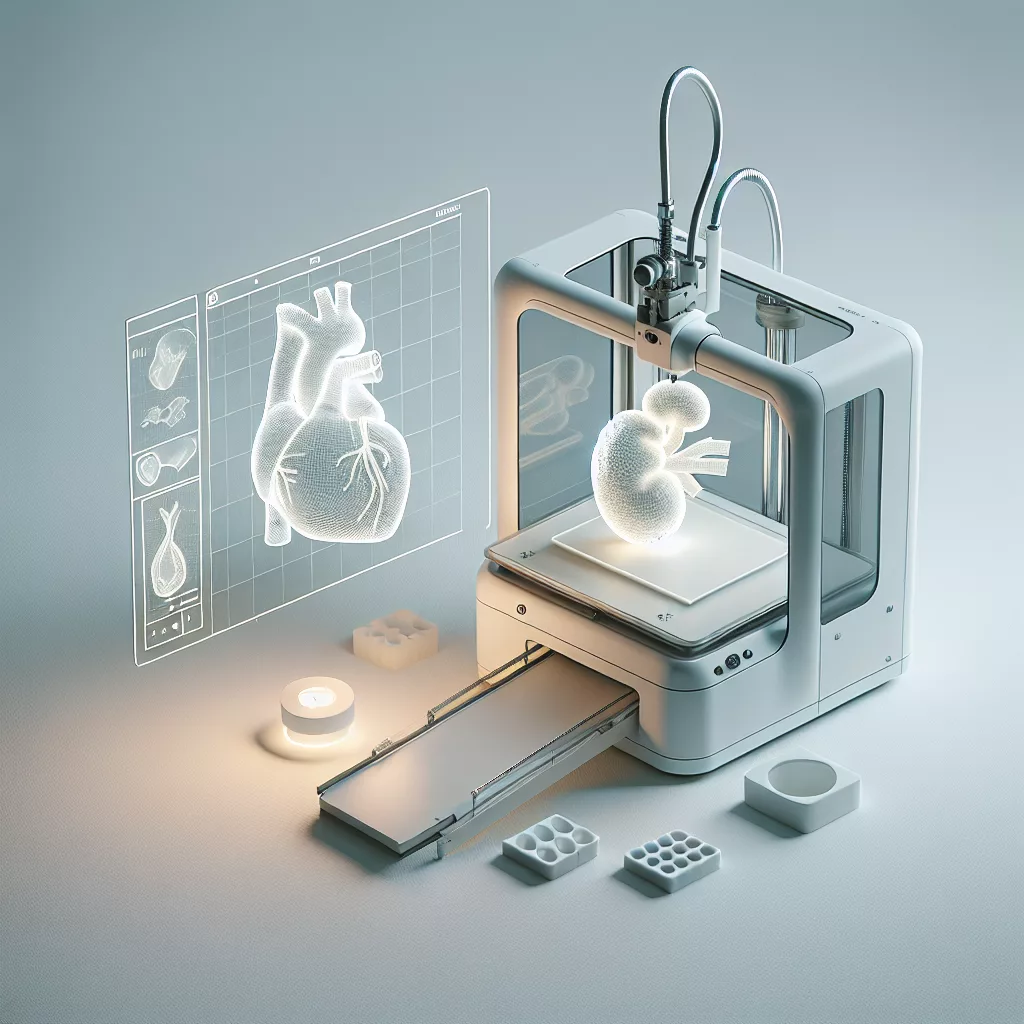

Modern Innovations and Expanding Material Options: 2010s Onwards

In the 2010s, improvements in hardware, software, and materials have vastly broadened 3D printing’s scope. Metal 3D printing technology, such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), became increasingly viable, revolutionizing aerospace, automotive, and healthcare industries. Moreover, breakthroughs in bioprinting opened groundbreaking possibilities in medicine, producing biological tissues and sophisticated prosthetics, and constantly pushing the limits of regenerative medicine.

Impact on Industries and Everyday Life Today

Today, 3D printing impacts virtually every industry, from aerospace and automotive to healthcare, education, and even fashion. Aerospace companies, including Boeing and SpaceX, utilize additive manufacturing to create lightweight, high-strength components. The medical sector has seen astounding advancements—custom prosthetics, personalized surgical equipment, and bioprinted tissues have elevated patient care significantly. Education sectors increasingly integrate 3D printing into curricula to teach students about engineering, creativity, and problem-solving. Even in homes, hobbyists and DIY enthusiasts enjoy accessible 3D printers, unleashing creativity and innovation.

The Future of 3D Printing: What’s Next?

Looking ahead, the future of 3D printing is promising, poised for further disruption and innovation. Advancements in speed, precision, and material science promise exponential growth. Emerging technologies, including multi-material printing, advanced composites, and large-scale additive manufacturing, will further redefine industries. Moreover, sustainability is expected to play a significant role—exploring recyclable materials, reducing waste, and optimizing design solutions to create more eco-friendly manufacturing processes.

In summary, from its humble beginnings in the 1980s to the integral role it plays today, 3D printing continues to evolve, transforming the way we create, innovate, and manufacture. The journey is far from complete, and the future holds even greater potential.

Leave a Reply