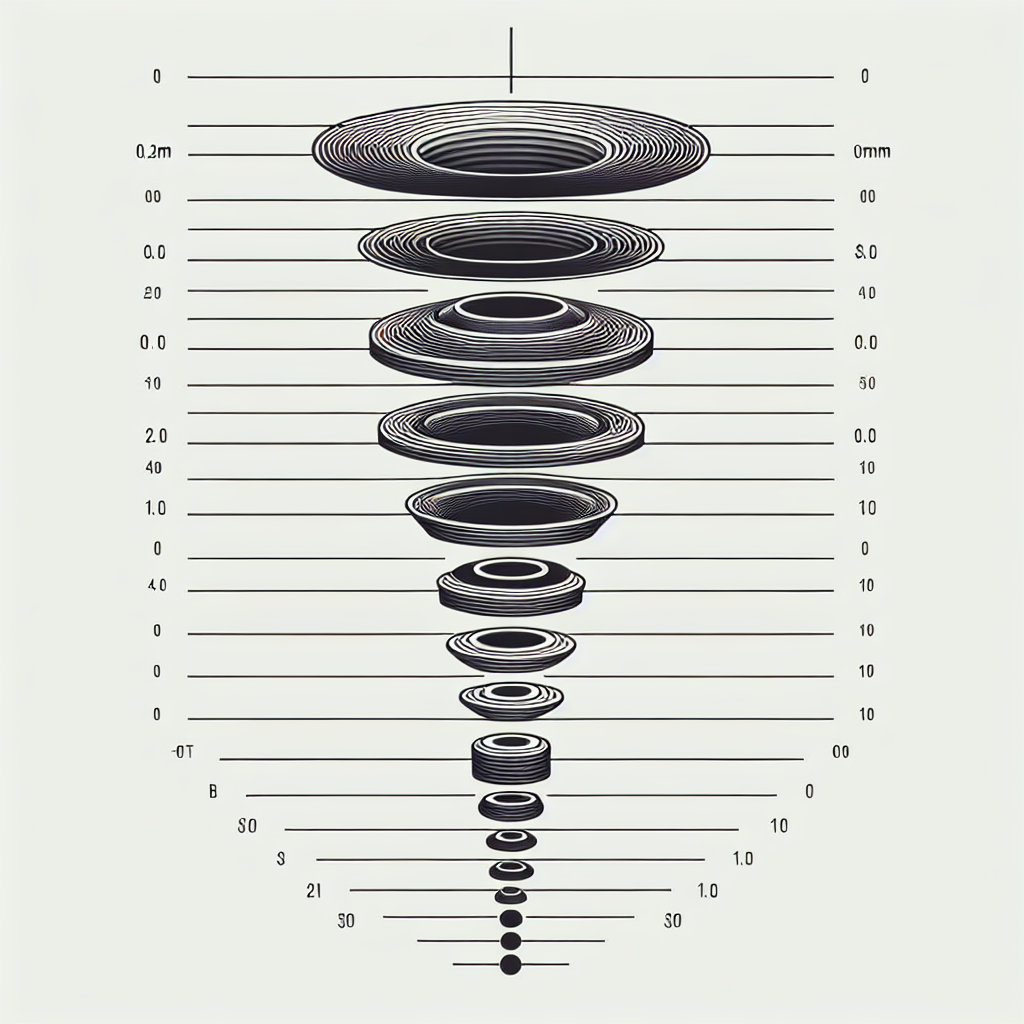

Understanding Nozzle Sizes in 3D Printing

When it comes to FDM (Fused Deposition Modeling) 3D printing, the nozzle size is a critical factor that directly impacts print quality, speed, and the type of projects you can undertake. The nozzle is the part through which melted filament is extruded, and its diameter determines how much material is laid down per pass. Whether you’re printing fine miniatures, large functional parts, or prototypes, choosing the right nozzle size can make a world of difference. Let’s break down the best nozzle sizes for different types of 3D printing and the scenarios where each excels.

The Standard: 0.4mm Nozzle

Most consumer 3D printers come equipped with a 0.4mm nozzle, and for good reason. This size strikes a balance between detail and speed, making it an excellent all-around choice for most applications. With a 0.4mm nozzle, you can print both finely detailed models and reasonably strong functional parts, while still achieving decent print speeds.

- Best for: General-purpose printing, prototyping, and hobbyist models.

- Resolution: Supports layer heights from 0.12mm up to 0.32mm.

- Filament Compatibility: Works well with standard PLA, PETG, ABS, and more.

High Detail: 0.2mm and 0.25mm Nozzles

If your primary focus is high-resolution prints, such as detailed figurines, jewelry prototypes, or architectural models, a smaller nozzle size like 0.2mm or 0.25mm is ideal. These nozzles allow for finer extrusion, resulting in smoother surfaces and more precise details.

- Best for: Miniatures, intricate models, and projects requiring high surface finish.

- Resolution: Supports layer heights as low as 0.05mm for ultra-fine detail.

- Trade-offs: Prints take significantly longer and are more susceptible to clogs. Not recommended for abrasive or fiber-filled filaments.

Speed and Strength: 0.6mm and 0.8mm Nozzles

For large-scale prints, functional parts, or when speed takes priority, larger nozzles like 0.6mm and 0.8mm are excellent choices. These nozzles extrude more filament per pass, dramatically decreasing print times while increasing part strength due to thicker extrusion lines.

- Best for: Rapid prototyping, large models, and mechanical parts.

- Resolution: Supports layer heights up to 0.6mm, but fine detail is reduced.

- Filament Compatibility: Better for abrasive filaments (with hardened nozzles), but less suitable for highly detailed aesthetic prints.

Specialty Nozzles: 1.0mm and Above

For extremely large prints or when using specialty filaments like carbon fiber, wood-filled, or glow-in-the-dark materials, nozzles sized 1.0mm or even larger can be used. These are less common but highly effective in industrial or artistic applications where durability and speed outweigh fine detail.

- Best for: Art installations, furniture, or functional prototypes that require significant strength and speed.

- Considerations: Very coarse surface finish, but excellent layer adhesion and durability.

Choosing the Right Nozzle for Your Project

The “best” nozzle size truly depends on your project’s goals. Here’s a quick guide:

- Miniatures & Fine Detail: 0.2mm – 0.25mm

- General Use & Prototyping: 0.4mm

- Large Parts & Fast Prints: 0.6mm – 0.8mm

- Massive Prints & Specialty Filaments: 1.0mm+

Remember, the nozzle isn’t the only factor at play—layer height, print speed, and material choice all interact. Always consider the filament’s flow characteristics and your printer’s capabilities before swapping out nozzles.

Pro Tips for Nozzle Changes and Maintenance

– Keep spares on hand: Nozzles are inexpensive, but crucial. Have backups in multiple sizes.

– Use the right tools: Invest in a quality nozzle wrench or socket to prevent damaging your hotend.

– Regular cleaning: Clean your nozzle with a cold pull or brass wire brush to avoid clogs.

– Check settings: Adjust slicer settings for extrusion width and layer height when changing nozzle sizes.

Conclusion

Selecting the right nozzle size is integral to achieving the desired balance of speed, detail, and mechanical performance in your 3D prints. From miniature gaming pieces to robust engineering prototypes, matching your nozzle to your project unlocks the true potential of your 3D printer. Experiment, observe, and don’t hesitate to swap out nozzles to see real improvements in your print quality and efficiency!

Leave a Reply