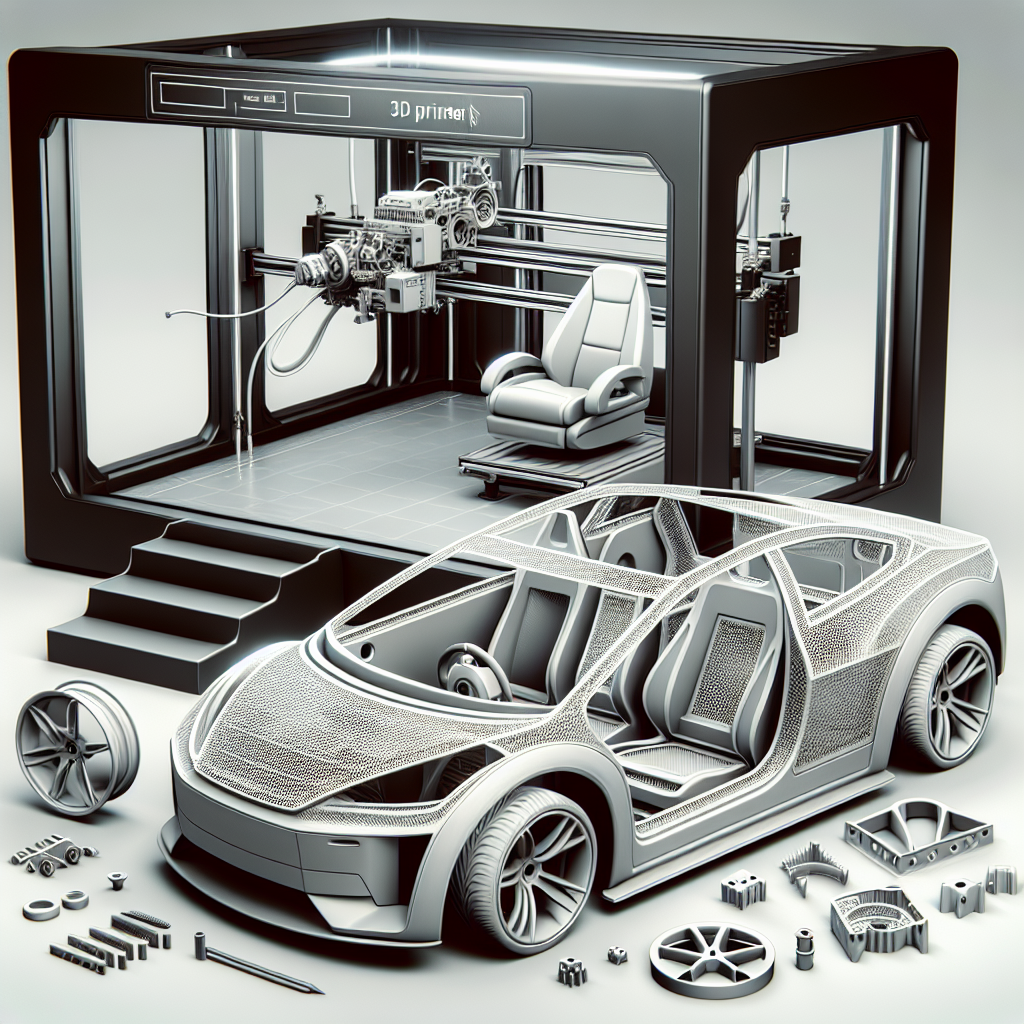

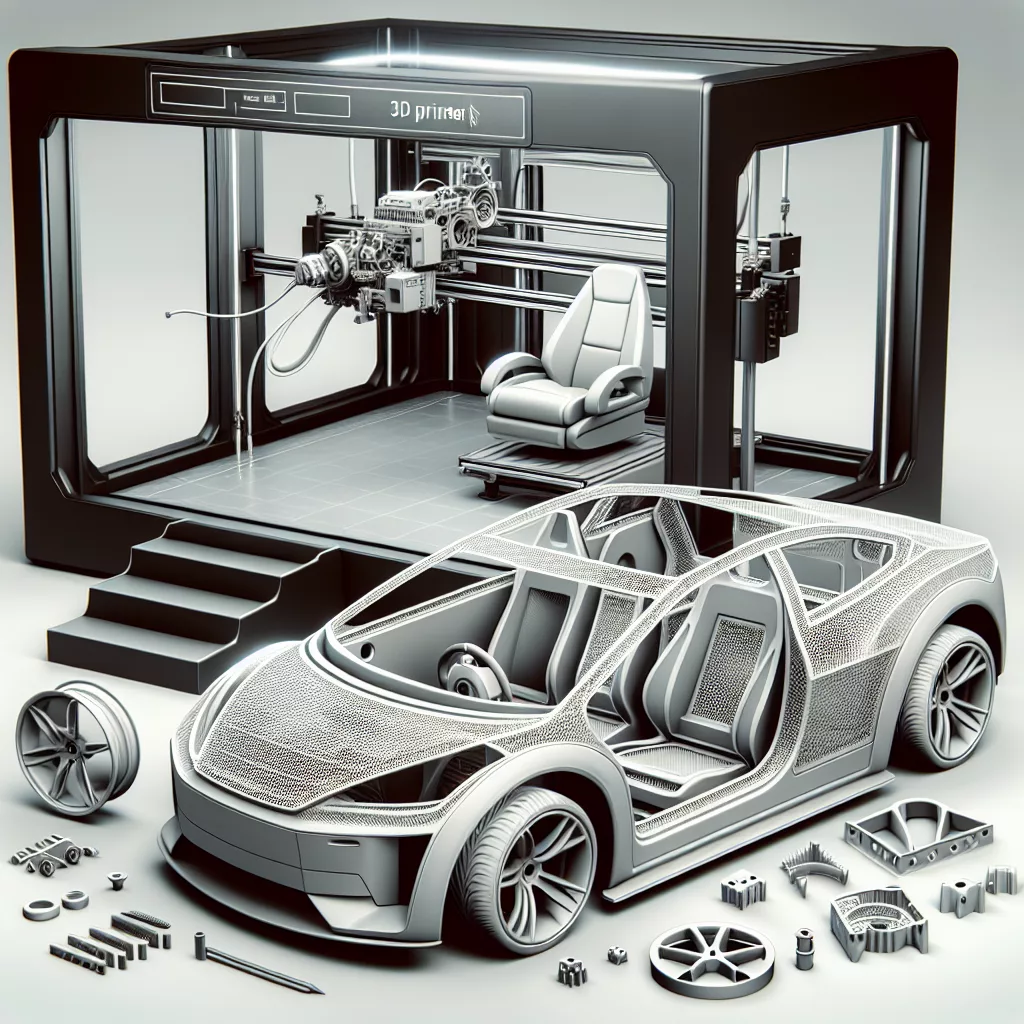

Introduction to 3D Printing in Automotive Industry

In recent years, 3D printing technology, also known as additive manufacturing, has significantly transformed various industries, with the automotive industry being one of its primary beneficiaries. Automotive manufacturers are increasingly adopting 3D printing technologies to enhance efficiency, reduce costs, and provide innovative solutions for vehicle production.

Rapid Prototyping: Accelerating Automotive Design

Traditionally, automotive prototyping was a costly and time-consuming process, often involving extensive manual labor and expensive machinery. However, 3D printing has revolutionized prototyping by dramatically reducing the turnaround time and costs associated with creating functional prototypes. Designers and engineers can now quickly iterate their designs, test new concepts, and make adjustments in real-time, drastically shortening development cycles.

Furthermore, additive manufacturing enables the production of complex geometries that are often impossible or economically unfeasible using traditional manufacturing methods. Lightweight structures, intricate internal support systems, and optimized components can be designed for superior performance and efficiency.

Customized Components and Personalized Vehicles

Personalization in the automotive industry has become increasingly popular. Consumers are eager to own vehicles that reflect their personal style and requirements. 3D printing makes it easier than ever to produce customized automotive components tailored specifically to the preferences of each customer. Interior components, tailored dashboards, personalized steering wheels, and even deeply customized body parts can be fabricated using additive manufacturing, providing manufacturers with a competitive edge in the marketplace.

Cost-Effective Production of Spare Parts

The automotive aftermarket represents another area where 3D printing shines. Traditionally, automotive manufacturers and suppliers have had to stock large inventories of spare parts, incurring significant expenses related to storage and logistics. With additive manufacturing, this need is significantly reduced, as spare parts can be printed on-demand. This approach not only helps reduce inventory costs but also extends the lifespan of discontinued vehicle models by enabling manufacturers to produce spare parts long after traditional supply chains have ceased production.

Improved Sustainability through Additive Manufacturing

Environmental concerns and regulatory requirements are increasingly placing pressure on automotive manufacturers to seek out sustainable manufacturing practices. 3D printing is known for its low-waste production method, as it only uses the precise amount of material required to build each part. This reduced waste generation contributes positively to the environmental footprint of vehicle manufacturing.

Additionally, the ability to create lightweight components through additive manufacturing leads to automotive vehicles with improved fuel efficiency and lower emissions, further aligning the automotive industry with sustainability goals.

Complex Structural Components and Performance Enhancement

Automotive performance is heavily influenced by vehicle weight, aerodynamics, and structural integrity. 3D printing enables the creation of lightweight but extremely strong structural components through methods such as topology optimization, a design process that intelligently distributes material only where needed for maximum functionality and minimal weight. As a result, manufacturers can create highly efficient vehicle parts that enhance overall performance, handling, and fuel efficiency.

Moreover, high-performance vehicles, racing cars, and luxury models are increasingly utilizing 3D-printed components to fine-tune performance parameters and achieve unparalleled results in motorsports.

Challenges and Future of 3D Printing in Automotive

Despite the numerous advantages, there are still some challenges to overcome in fully integrating 3D printing in automotive production workflows. Material limitations, speed constraints, quality consistency, and economic feasibility for mass production remain areas for improvement.

Nevertheless, technological advancements continue to rapidly progress, and the future of additive manufacturing in the automotive industry is extremely promising. New materials, faster printing technologies, and increasingly sophisticated software solutions are continually emerging, providing further opportunities for automotive manufacturers to leverage 3D printing capabilities.

Conclusion

The automotive industry has embraced 3D printing technology as a transformative force capable of improving product design, customization, cost efficiency, and sustainability. With continued research and innovation, additive manufacturing is poised to become an even more integral part of automotive manufacturing processes, fundamentally reshaping the way vehicles are envisioned, developed, and produced.

Leave a Reply