Introduction: The Promise of 3D Printed Homes

The dream of affordable, sustainable, and quickly constructed housing is inching ever closer to reality, thanks to remarkable advancements in 3D printing technology. What seemed like science fiction just a decade ago has become an exciting frontier in construction today. But how realistic is it to imagine living in houses built layer by layer, using giant 3D printers? Let’s explore the current state and future possibilities of 3D printed homes.

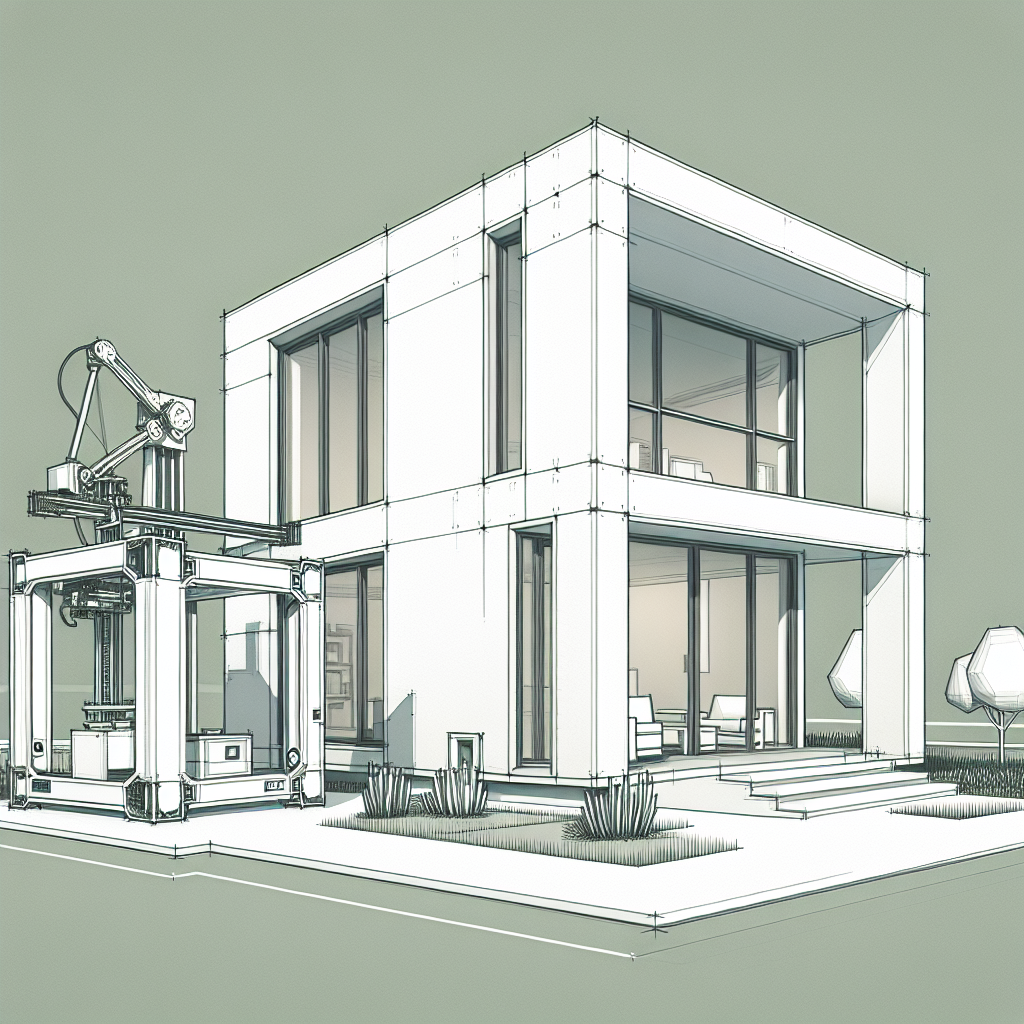

How Does 3D Printing for Homes Work?

At its core, 3D printing a home involves depositing an extrusion of concrete or other construction materials layer-by-layer, following digital blueprints created using Computer-Aided Design (CAD) software. Large-scale printers, guided by robotic arms or gantry systems, systematically build walls and structural elements by precisely laying down layers in predetermined patterns.

Materials commonly used in 3D printed construction include cement-based composites, specialized concrete mixes, and even innovative materials like recycled plastics and bio-based composites. The flexibility of material selection allows builders to optimize for strength, insulation, and sustainability, making 3D printed homes an extremely attractive option in a world demanding environmentally friendly solutions.

The Benefits: Why Pursue 3D Printed Housing?

Speed and Efficiency

Traditional home construction can often stretch months or even years, but 3D printed structures significantly speed up the building process. By automating construction, 3D printing can erect walls and structures in days or weeks rather than months, vastly reducing labor hours and speeding up the move-in timeline.

Cost Reduction

Due to reduced labor costs, fewer wasted materials, and optimized processes, 3D printing homes can dramatically decrease construction expenses. This affordability offers significant potential for addressing global housing shortages and providing accessible housing solutions to low-income communities.

Architectural Freedom

3D printing enables architects and designers to break free of traditional design constraints. Complex geometric shapes, curved walls, and customized details can be built with the same ease as standard rectangular structures, allowing unique, personalized homes that reflect modern styles and individual tastes.

Sustainability and Environmental Impact

3D printing construction processes typically generate less waste, reducing overall environmental impact. Additionally, the ability to integrate sustainable and recycled materials further lowers the ecological footprint of printed homes, making them an appealing option for environmentally-conscious communities.

Real-World Applications: Current Examples of 3D Printed Homes

Several pioneering projects around the globe have successfully demonstrated the feasibility of 3D printed housing:

– ICON and New Story Housing Project (Texas, USA): In Texas, ICON partnered with New Story, a housing non-profit, to construct affordable, resilient homes using their Vulcan 3D printer. The homes were completed in days rather than weeks and demonstrated affordability and durability.

– Apis Cor’s Printed House (Russia): Apis Cor demonstrated its mobile construction printer by building a fully functional house in 24 hours in severe weather conditions, highlighting the printer’s versatility and adaptability to various environments.

– TECLA Project (Italy): Built entirely from locally sourced clay materials, the TECLA project showcases how sustainable, eco-friendly homes can be rapidly created using 3D printing technology.

These real-world accomplishments confirm that 3D printed homes aren’t merely experimental concepts; they’re increasingly practical housing solutions ready for widespread adoption.

Challenges and Hurdles to Overcome

Although promising, 3D printed homes still face certain hurdles before becoming mainstream:

– Regulatory and Building Code Issues: Many local building codes and standards have yet to adapt to incorporate printed construction methods, leading to delays and uncertainties in approval processes.

– Material Durability and Longevity: While 3D printing technology is rapidly advancing, the long-term durability of printed structures still requires continued testing and validation.

– Scale and Accessibility: Large-scale 3D printers suitable for home construction are expensive to build and maintain, limiting scalability and accessibility in diverse global markets.

Addressing these challenges will require continued research, development, collaboration between regulatory bodies, industry professionals, and technology developers.

The Future Outlook: Living in a 3D Printed World?

As we look forward, the trajectory of 3D printed homes is undeniably promising. With continued innovation, collaboration, and investment, it’s becoming clear that we’re moving closer to a reality where 3D printed homes become a commonplace and reliable housing solution. From affordable housing initiatives and disaster relief to eco-friendly communities and personalized architecture, the potential applications are immense and exciting.

Conclusion: Getting Closer Every Day

The vision of living in a printed home is quickly transitioning from futuristic dream to practical reality. While challenges remain, the tremendous progress of the past decade signals we are closer than ever to widespread adoption. As technology evolves, regulations adapt, and industries embrace innovation, we may soon find our next home fabricated layer by layer, ushering in a new era of efficient, affordable, and sustainable living.

Leave a Reply