Introduction to SLA 3D Printing

Stereolithography, more commonly known as SLA 3D printing, is one of the most precise and oldest forms of additive manufacturing technology. Invented in the 1980s, this technology is still a popular choice for creating detailed prototypes, complex components, and other high-quality parts. If you’re new to 3D printing or curious about expanding your understanding of its possibilities, SLA technology is an excellent place to start.

How Does SLA 3D Printing Work?

SLA 3D printing operates on the principle of photopolymerization. Essentially, a powerful ultraviolet laser selectively cures (hardens) liquid resin layer by layer to form a solid object. The process begins by submerging a build platform into a vat filled with liquid resin. The UV laser beam then traces the cross-sectional pattern of the object onto the resin surface, solidifying it. After one layer solidifies, the platform moves slightly, and the laser traces the next layer. This process repeats until the entire object is complete.

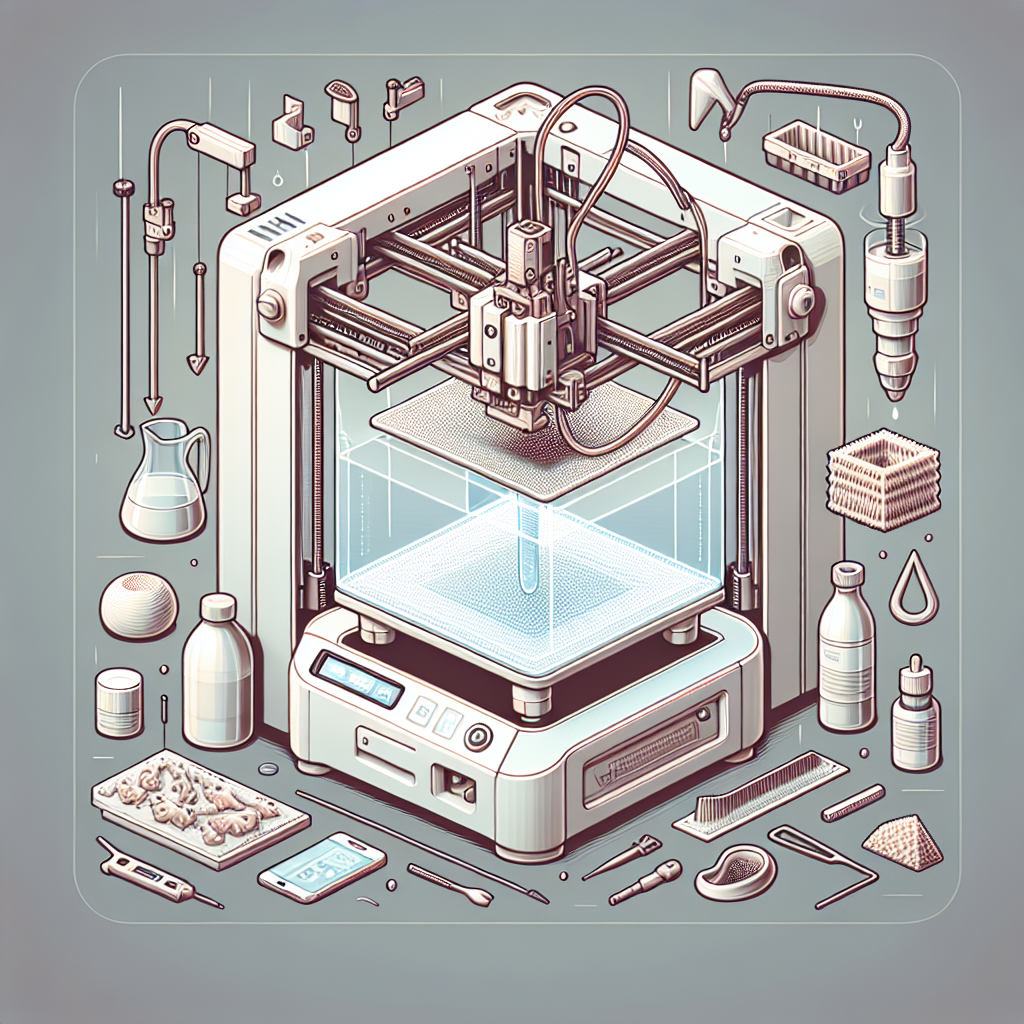

The Essential Components of an SLA 3D Printer

While SLA printers vary in size, function, and complexity, they generally share these fundamental components:

- Laser Source: Usually an ultraviolet laser, which selectively cures the resin.

- Resin Vat: A transparent or semi-transparent container holding photosensitive resin.

- Build Platform: The surface onto which the object is printed layer by layer.

- Elevator Mechanism: The motorized system that moves the build platform up or down as each layer cures.

- Control Software: Specialized software that converts digital 3D designs into instructions for the printer.

Advantages of SLA 3D Printing

SLA printing boasts several key advantages, making it a preferred method for specific applications.

- High Precision and Resolution: SLA printers create objects with exceptional accuracy, fine details, and smooth surface finishes.

- Complex Geometry: SLA can easily handle intricate geometries, thin walls, and complex internal structures, which are challenging or impossible to create through traditional manufacturing.

- Material Versatility: A wide range of resins are available for SLA, each tailored for different mechanical and aesthetic properties, including flexibility, hardness, heat resistance, and transparency.

Common Applications of SLA 3D Printing

With its high resolution and exceptional detail, SLA 3D printing finds use in numerous industries:

- Prototyping: Rapid prototyping of products or components requiring high accuracy and aesthetic appeal.

- Healthcare and Dental: Custom dental models, surgical guides, and medical prototypes.

- Jewelry and Arts: Detailed and intricate casting patterns for jewelry and decorative objects.

- Engineering and Automotive: Functional prototypes, complex tooling molds, and custom parts for engineering purposes.

Challenges and Limitations of SLA Printing

Despite its benefits, SLA printing has some limitations worth considering:

- Cost of Materials: SLA resins can be more expensive than other 3D printing materials, such as filament used in FDM printing.

- Post-Processing Requirements: Finished prints often require post-processing steps, such as washing, curing with UV light, and removing support structures.

- Material Properties: Some SLA resins may not have the strength or durability needed for certain functional, load-bearing applications.

Tips for Successful SLA 3D Printing

Here are some beginner-friendly tips to ensure you get the best results from your SLA printers:

- Proper Resin Handling: Resins require careful handling; always use gloves, safety glasses, and proper ventilation to ensure safe printing.

- Optimized Orientation: Orient your models to minimize support structures and improve surface finish.

- Consistent Maintenance: Regularly clean and inspect your resin vat, build platform, and other components to prevent issues and maintain print quality.

- Post-Processing Precision: Invest in proper equipment, such as dedicated wash and cure stations, to enhance your final print quality.

Conclusion

SLA 3D printing provides unparalleled precision, detail, and surface finish, making it a favorite technology for professionals across various industries. With a clear understanding of how SLA works, its advantages, limitations, and best practices, you’ll be ready to explore this exciting additive manufacturing technology and unlock its potential for your projects.

Leave a Reply