Understanding Water-Soluble Supports in 3D Printing

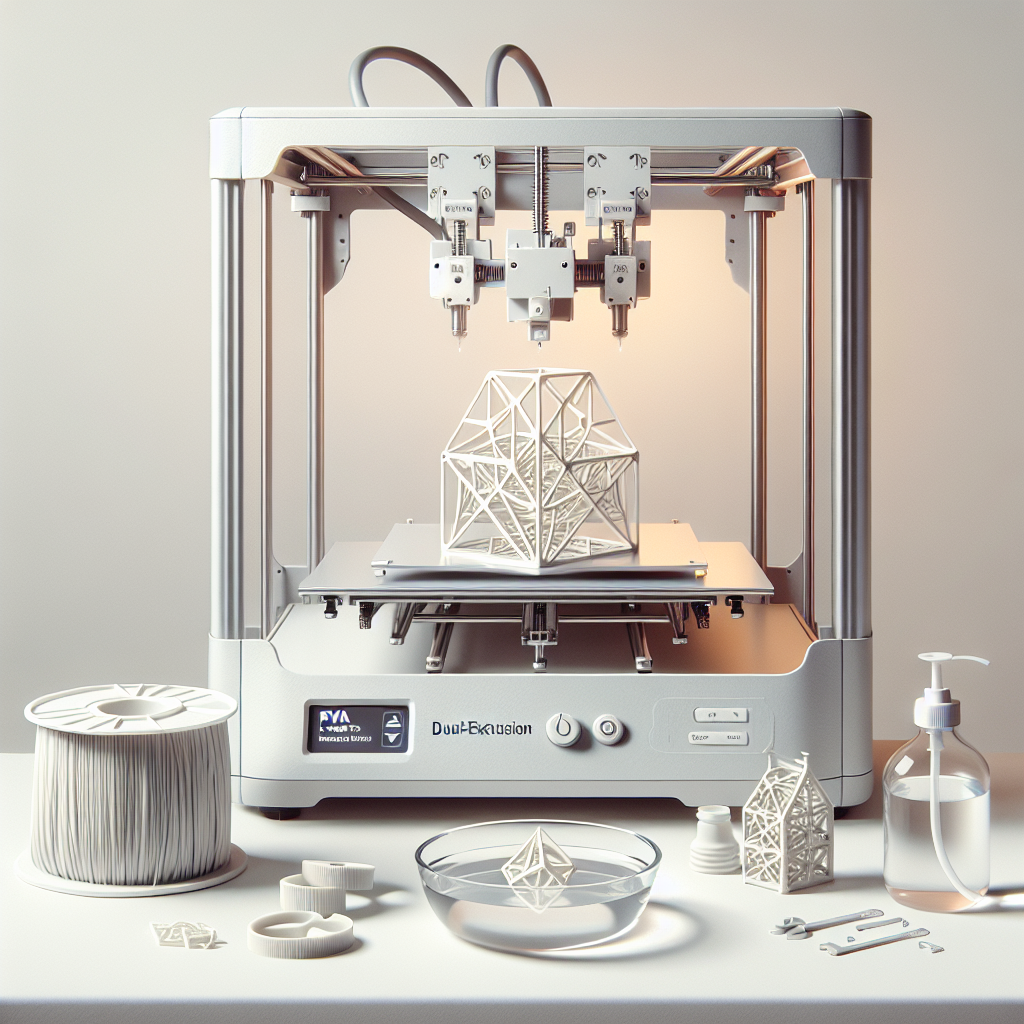

One of the most transformative innovations in desktop 3D printing is the use of water-soluble support materials. These supports, commonly made from PVA or BVOH, dissolve in water after printing, making it possible to achieve smoother surfaces, complex overhangs, and intricate geometries that would be otherwise impossible or time-consuming to clean up. In this article, I’ll walk you through how to use water-soluble supports for cleaner prints, drawing from years of hands-on experience in the field.

What Are Water-Soluble Support Materials?

Water-soluble supports are separate filament materials designed to act as scaffolding for parts of your print that need support—such as overhangs, bridges, or internal cavities. The two most popular options are PVA (polyvinyl alcohol) and BVOH (butenediol vinyl alcohol copolymer). Both dissolve in water, though BVOH tends to dissolve faster and clean up even easier.

These supports are especially useful in dual-extrusion 3D printers, where one extruder prints your primary material (like PLA or PETG) and the other handles the support material.

Benefits of Using Water-Soluble Supports

- Cleaner Surface Finish: No more rough marks or gouges left behind from manually removed supports.

- Complex Geometries: Print intricate, interlocking, or hollow parts without worrying about reaching or removing hard-to-access support material.

- Time-Saving: Let the water do the work of cleanup, freeing you from tedious sanding or scraping.

- Reduced Breakage: Fragile features are better protected because supports wash away instead of snapping off.

How to Set Up Your Printer for Water-Soluble Supports

- Dual Extruder Required: For most use-cases, you’ll need a dual-extruder printer. Assign the primary extruder to your main filament (PLA, PETG, etc.) and the secondary to your soluble support.

- Keep Material Dry: Both PVA and BVOH are hygroscopic and absorb moisture quickly. Store them in airtight containers with desiccant. If your support filament gets soft, brittle, or bubbles during printing, dry it in a filament dryer before use.

- Optimize Slicer Settings: Configure your slicer (like Cura, PrusaSlicer, or Simplify3D) to recognize which extruder holds the support. Adjust the support settings for “soluble support material” and tweak support density, interface layers, and Z-gap for best results.

- Bed Adhesion: Water-soluble supports sometimes struggle with bed adhesion. Use a glue stick, PEI sheet, or build plate adhesive as needed to prevent warping or detachment during printing.

Printing with Water-Soluble Supports: Tips and Tricks

- Temperature Matching: Choose main print materials that have similar print temperatures to the support. For example, PVA works well with PLA, while BVOH is better suited for PETG or ABS.

- Slow Down for Quality: Print supports at a slightly slower speed for better layer adhesion and cleaner separation.

- Use Support Interface Layers: Many slicers offer a “support interface” or “dense support” setting. Enabling this creates a smoother boundary between your model and the supports, further improving surface quality and ease of removal.

- Monitor First Layers: Water-soluble supports can sometimes string or ooze more than standard materials. Watch the first few layers and adjust retraction and print temperature as needed.

How to Remove Water-Soluble Supports

- Initial Rinse: After printing, carefully remove your model from the build plate, avoiding any force on delicate features.

- Soak in Water: Place the model in a container of room-temperature water. Gently agitate the water to help the dissolution process. For faster results, use lukewarm (not hot!) water, but avoid temperatures above 40°C for PVA to prevent warping or deforming your print.

- Change Water as Needed: If the water becomes cloudy or saturated with dissolved material, replace it to continue dissolving supports effectively.

- Final Rinse and Dry: Once the supports are gone, give your print a final rinse in clean water and allow it to air dry completely.

Troubleshooting Common Issues

- Support Not Dissolving: Ensure water is fresh and at the right temperature. If supports are very thick, use a toothbrush to gently agitate and help break up the material.

- Stringing or Oozing: Lowering print temperature or increasing retraction distance can help reduce stringing of PVA/BVOH.

- Bed Adhesion Problems: Apply a thin layer of glue stick, or use a build surface better suited for PVA/BVOH if you’re seeing curling or detachment.

Conclusion: Elevate Your Prints with Water-Soluble Supports

Water-soluble supports unlock new possibilities in 3D printing, making intricate and delicate models easier to print and finish with professional, clean results. With the right setup and a little practice, you’ll find water-soluble supports save time, reduce post-processing effort, and vastly improve the quality of your 3D prints. Whether you’re a hobbyist or a professional, incorporating water-soluble support materials is a game-changer for achieving cleaner, more complex prints.

Leave a Reply