Why Proper Filament Storage Matters

Proper storage of 3D printing filament is critical to maintaining print quality and ensuring the longevity of your materials. Filaments like PLA, ABS, PETG, TPU, and especially nylon are hygroscopic—meaning they readily absorb moisture from their surroundings. Moisture absorption can result in poor print quality, decreased strength, and clogged printer nozzles. To avoid these issues, it’s essential to know exactly how to store filament correctly.

Signs Your Filament Has Absorbed Moisture

Before diving into storage techniques, it’s important to recognize the signs of moisture-compromised filament:

- Popping or crackling noises while printing

- Rough surface finish on printed models

- Inconsistent extrusion or stringing

- Brittleness or weakness in printed parts

If you notice these symptoms, your filament has likely absorbed too much moisture and requires drying before further use.

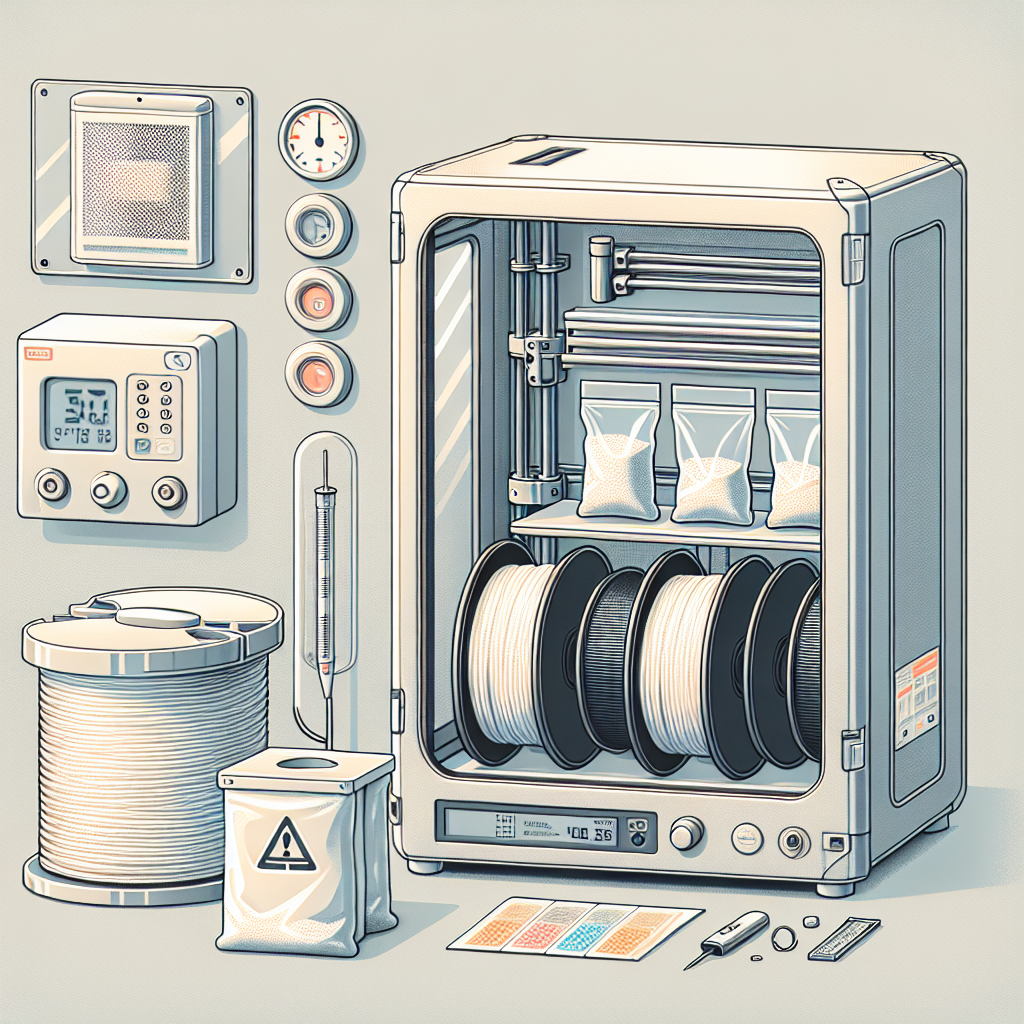

Choosing the Right Storage Container

Your first step to proper filament storage is selecting the ideal container. An airtight storage solution is essential. Here are a few effective options:

- Vacuum-sealed Bags: Ideal for long-term filament storage. These bags remove excess air and moisture, ensuring your filament stays fresh.

- Plastic Storage Containers with Rubber Seals: A cost-effective solution for storing multiple spools. Choose containers big enough to comfortably hold the spools, ideally with minimal air inside.

- Dry Boxes: Specialized solutions that not only store filament but also allow you to print directly from them, keeping your filament dry even during printing.

Using Desiccants Effectively

A crucial component of filament storage is using desiccants—substances that absorb moisture from the air. Silica gel packs are the most common desiccants used in filament storage. Here’s how to maximize their effectiveness:

- Place several silica gel packs or moisture absorber packs inside your filament container, ideally positioned around the spool.

- Use color-indicating silica gel packs; these change color when saturated to alert you when rejuvenation (drying) is needed.

- Periodically recharge silica gel packs by drying them in an oven or microwave to maintain their moisture-absorbing capabilities.

Optimal Storage Environment

Even airtight containers function best when stored under proper environmental conditions. Keep these storage tips in mind:

- Temperature: Store filament at room temperature (~18-25°C or 64-77°F). Avoid areas with extreme temperatures or temperature fluctuations.

- Humidity: Aim for low humidity environments (below 30% relative humidity, if possible).

- Sunlight: Keep filament containers away from direct sunlight or UV exposure, as UV rays can degrade filament quality and strength over time.

Filament Drying Techniques

If your filament has already absorbed moisture, don’t worry—you can still restore it to optimal printing condition. There are several effective drying methods:

- Filament Dryers: Specialty dryers designed specifically for filament. They gently heat and circulate air around the spool to slowly remove moisture without damaging the filament.

- Food Dehydrators: An affordable and effective method to dry filament evenly. Set temperatures around 45°C (113°F) for PLA, 60°C (140°F) for ABS/PETG, and slightly higher for nylon.

- Oven Drying: While possible, oven drying is the riskiest option. Use low and accurate temperatures (below the filament’s glass transition point) and monitor continuously. Always test on small filament samples first to ensure no melting occurs.

Filament Storage Best Practices

To summarize, let’s review the best practices for properly storing your 3D printing filament:

- Always store filament in sealed, airtight containers or vacuum-sealed bags.

- Include desiccants to actively reduce humidity levels.

- Keep storage containers in a cool, dry place away from direct sunlight.

- Regularly inspect and recharge desiccants.

- Dry filament thoroughly if moisture exposure has already occurred.

Implementing these strategies will ensure your filament maintains optimal quality and performance, resulting in consistent, high-quality 3D prints.

Leave a Reply