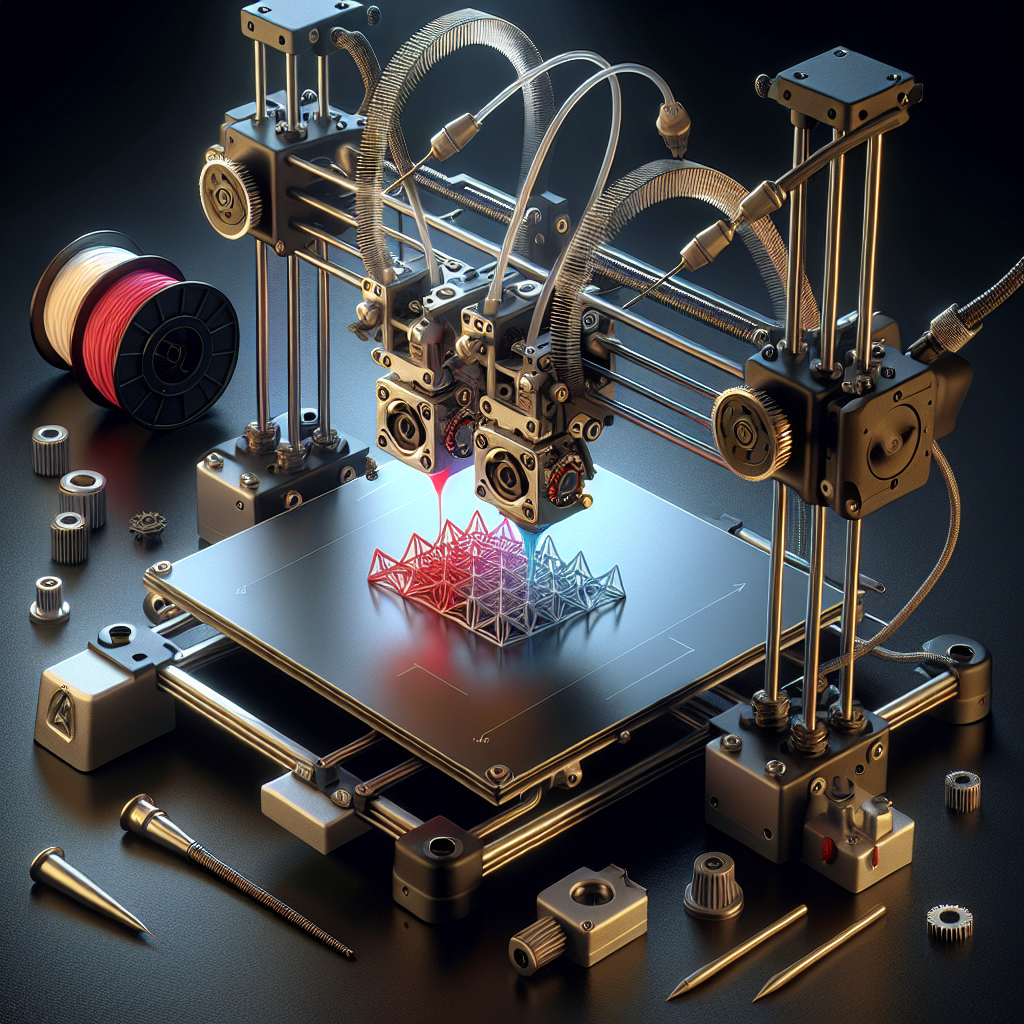

Understanding Dual Extruder 3D Printing

Dual extruder 3D printers have unlocked new possibilities in the world of additive manufacturing, allowing creators to print with two different filaments in a single job. This opens the door for printing objects with multiple colors, combining materials with distinct properties, or using soluble support materials for complex geometries. Whether you’re a hobbyist or a professional, mastering dual extruder setups is a game changer for multi-material prints.

Benefits of Dual Extruder Printing

Using dual extruders offers several advantages:

- Multi-Color Prints: Easily print objects with two colors, allowing for intricate designs and color-coded parts.

- Multi-Material Capabilities: Combine flexible and rigid filaments, or mix technical materials for functional prototypes.

- Soluble Supports: Use soluble filaments like PVA or HIPS for support structures, simplifying the post-processing of complex models.

Preparing Your Printer for Dual Extrusion

Before tackling your first dual extruder print, ensure your printer is correctly set up:

- Firmware Configuration: Verify that your 3D printer’s firmware supports dual extrusion and that both extruders are properly calibrated.

- Hardware Check: Ensure both hotends are clean and properly leveled. Nozzle heights must match to avoid uneven first layers or nozzle collision.

- Material Compatibility: Choose filaments that have similar printing temperatures and are compatible—this is crucial for reliable dual-material prints.

Designing and Preparing Models for Dual Extrusion

To take full advantage of dual extrusion, you’ll need 3D models designed for multiple materials:

- Multi-Body Models: Design your model with separate bodies or “parts” that correspond to each filament. Many slicers accept multi-part STL files or 3MF projects.

- Alignment: Ensure model parts are perfectly aligned. They must fit together seamlessly in the slicing software for proper results.

Using Slicer Software

Slicing is the most critical step in dual extruder printing. Popular slicers like PrusaSlicer, Cura, and Simplify3D support multi-extruder setups. Here’s how to get started:

- Load Multi-Part Files: Import all model parts into the slicer, assign each to the correct extruder.

- Material Assignment: Choose filament types for each extruder in your slicer settings.

- Wipe and Prime Towers: Enable wipe or prime towers to prevent color or material contamination when switching extruders. These towers purge the nozzle of residual filament before resuming the print.

- Ooze Shields: Use ooze shields to catch stray filament during tool changes, reducing stringing and color bleeding.

- Support Settings: Configure supports to use a different material (e.g., PVA for water-soluble supports), and adjust support interface settings for easy removal.

Best Practices for Successful Dual Extruder Prints

Drawing from years of hands-on experience, here are some key tips:

- Calibrate Offsets: Carefully calibrate X and Y offsets between extruders to ensure material alignment. Most slicers have built-in tools or wizards for this step.

- Optimize Retraction: Fine-tune retraction and temperature settings for each filament to minimize stringing and prevent jams.

- Balance Print Speeds: Slower print speeds during material transitions can improve print quality and reduce defects.

- Monitor the First Layers: Keep a close eye on the first few layers. Dual extrusion increases the risk of adhesion problems or nozzle clashes.

- Experiment with Materials: Start with two PLA filaments before progressing to more challenging combinations like PLA/PVA or rigid/flexible pairings.

Troubleshooting Common Dual Extruder Issues

Even with the best preparation, you may encounter challenges:

- Color Bleeding or Contamination: Increase the size of the wipe tower or enable an ooze shield. Lower print temperatures can also help reduce oozing.

- Support Removal Problems: Double-check that the support interface is set to a different material. Adjust interface thickness and density in your slicer.

- Filament Jams or Clogs: Check nozzle cleanliness and ensure both filaments are feeding smoothly. Regular maintenance prevents most extrusion issues.

Conclusion

Dual extruder 3D printing is a powerful technique for anyone looking to create complex, multi-material, or multi-color prints. With proper printer setup, thoughtful slicing, and regular calibration, you’ll unlock a new level of creativity and functionality in your 3D printing projects. The learning curve can be steep, but the results—whether it’s visually striking models, soluble-supported engineering prototypes, or innovative material blends—are well worth the effort. Happy printing!

Leave a Reply