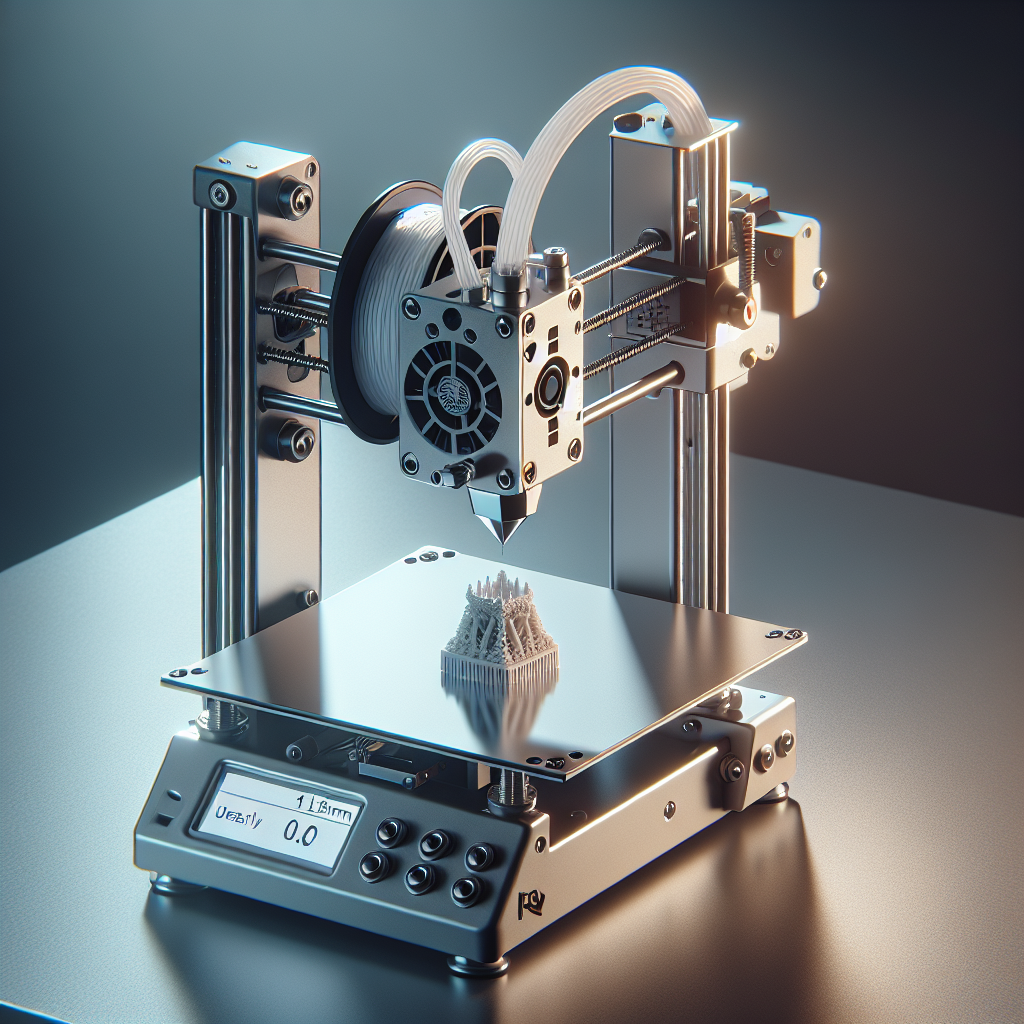

Understanding the Limits of FDM Printing

Fused Deposition Modeling (FDM) 3D printers are celebrated for their versatility, affordability, and accessibility, but they often get overlooked when it comes to ultra-fine detail work. While resin printers are the industry standard for miniatures and intricate models, a well-tuned FDM printer can achieve surprisingly detailed results. The key lies in understanding the inherent limitations of the technology and how to optimize every aspect of your workflow.

Choosing the Right Nozzle

The most crucial factor in printing fine details is the nozzle diameter. Standard FDM printers typically come with a 0.4mm nozzle. For ultra-fine details, consider swapping to a 0.2mm or even 0.15mm nozzle. Remember, the smaller the nozzle, the finer the detail—but also the longer the print time and the higher the risk of clogging. Use high-quality, clean filament and ensure your extruder is in top condition to prevent jams.

Dialing in Layer Height

Layer height is another principal variable. For the finest details, set your layer height to 25-50% of your nozzle diameter. With a 0.2mm nozzle, this means layer heights of 0.05mm to 0.1mm. This dramatically increases print time but yields smoother surfaces and sharper features.

Material Selection Matters

Not all filaments are created equal. For ultra-fine work, PLA is a strong choice due to its ease of use and minimal warping. Look for high-quality, consistent-diameter filaments. Specialty PLA blends designed for detail, like “Silk” PLAs or engineering-grade PLAs, can make a difference in the final finish.

Optimizing Print Speed and Temperature

Fine detail printing demands slow, steady operation. Lowering your print speed—sometimes as slow as 20-30mm/s—gives the filament time to cool and settle before the next layer is extruded, reducing ooze and stringing. Additionally, lower extrusion temperatures within the recommended range for your material can help minimize blobbing and stringing, both of which obscure fine features.

Tuning Cooling and Retraction

Adequate cooling is critical for capturing sharp edges and details, especially on small features. Ensure your part cooling fan is functioning optimally, and consider increasing its speed for fine detail prints. Retraction settings are equally vital. Test and calibrate these settings to prevent stringing without causing under-extrusion.

Model Preparation and Slicer Settings

The best hardware setup can’t compensate for poor model preparation. Make sure the model is designed for printability at your chosen scale and nozzle size; features smaller than your nozzle cannot be printed. In your slicing software, enable features like “detect thin walls,” and reduce print speeds for external perimeters. Also, use the highest quality (lowest layer height) profiles available, and consider turning on “ironing” for ultra-smooth top layers.

Printer Calibration and Maintenance

A finely-tuned printer is essential for ultra-detail work. Regularly calibrate your extruder steps/mm, check bed leveling, and ensure there’s no play in belts or the printhead. Lubricate moving parts and verify the bed surface is clean and in good condition. Any mechanical inconsistencies will be magnified at small scales.

Environmental Considerations

Ambient temperature and airflow can influence print quality. Drafts or fluctuating temperatures can cause warping or layer shifting. Print in a controlled environment, or enclose your printer if possible, to keep conditions stable throughout the print.

Post-Processing for Perfection

After printing, small flaws can be corrected with gentle sanding, scraping, or even a touch of solvent smoothing if using compatible materials. For models requiring assembly, careful planning of orientation and support placement during slicing can minimize the need for heavy post-processing.

Takeaway: Patience and Precision

Achieving ultra-fine detail on an FDM 3D printer is absolutely possible, but it demands patience, attention to detail, and a willingness to experiment. Each printer and material combination will have its own “sweet spot.” With the right setup and careful tuning, you’ll be surprised just how far you can push your FDM printer’s capabilities. Happy printing!

Leave a Reply