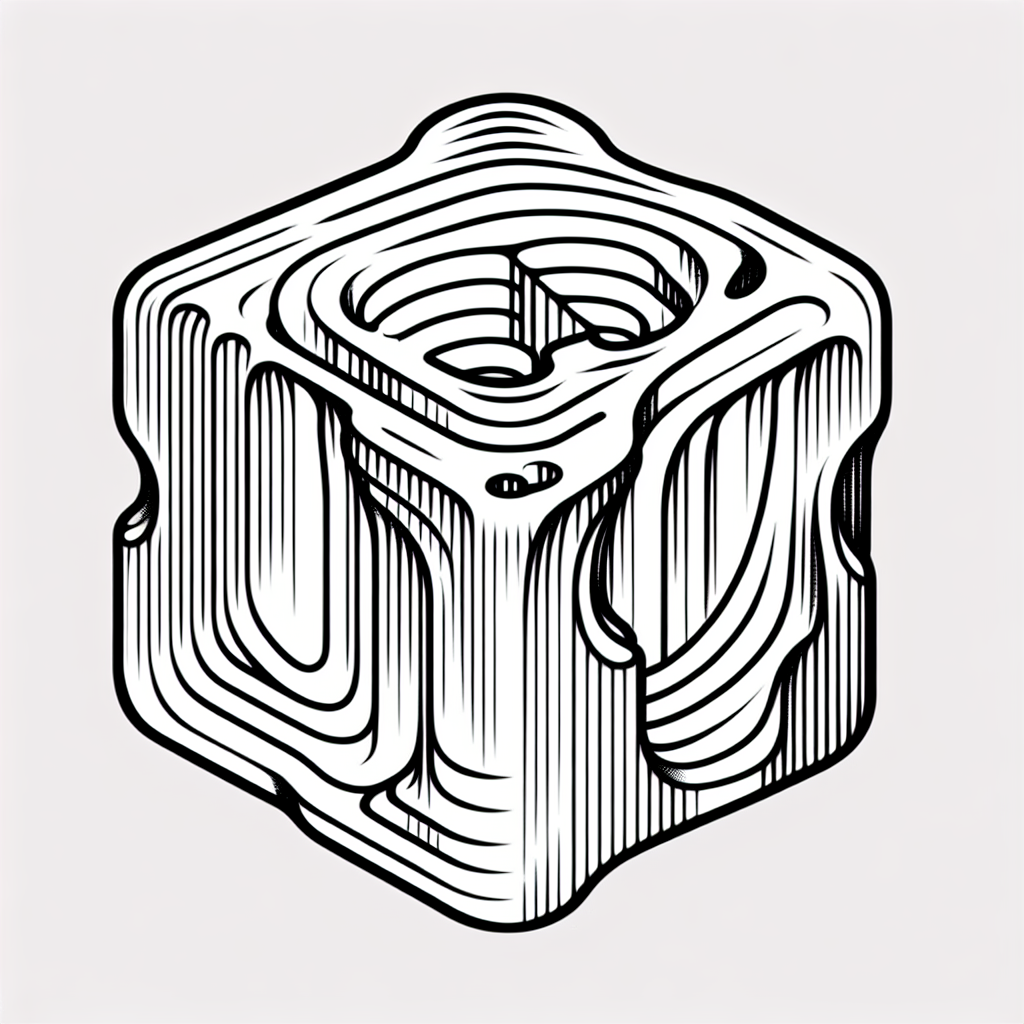

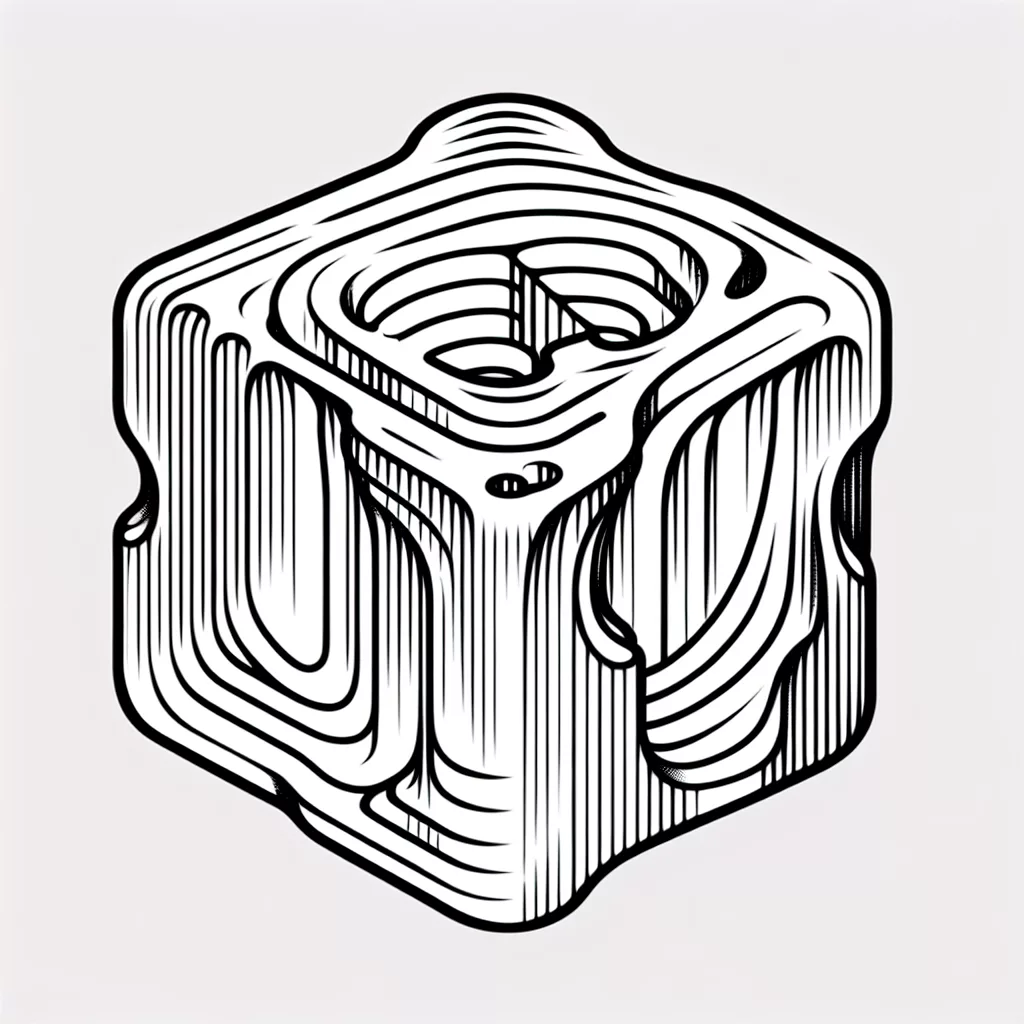

Under-extrusion in 3D printing is a common but frustrating problem that occurs when your 3D printer doesn’t push out enough filament, causing weak, incomplete, or visibly flawed prints. Fortunately, this problem is usually straightforward to diagnose and resolve. In this guide, we’ll explore the primary causes of under-extrusion and outline practical solutions you can apply immediately.

What Is Under-Extrusion in 3D Printing?

Under-extrusion happens when your printer fails to extrude the right amount of filament, resulting in gaps, weak layers, and poor aesthetic quality. It often manifests as thin lines, holes in printed surfaces, layers not bonding properly, or incomplete layers.

Common Causes and Solutions for Under-Extrusion

1. Incorrect Print Temperature

The most common cause of under-extrusion is incorrect printing temperature. If the filament isn’t heated enough, it won’t flow smoothly, causing inconsistent extrusion.

Solution: Check your filament manufacturer’s recommended temperature range and adjust your printer settings accordingly. Gradually increase the temperature by 5°C increments until you see improved extrusion.

2. Clogged or Partial Nozzle Blockage

A clogged nozzle or partial blockage can seriously impede filament flow. Dust, debris, or burnt filament residue can gradually build up, causing filament feeding issues.

Solution: Clean your nozzle thoroughly. You can perform a cold-pull, which involves heating your nozzle to printing temperature and manually pulling filament out to clear the nozzle. Alternatively, use a fine needle to gently remove debris from the nozzle tip when hot (be cautious and use protective gloves).

3. Improperly Adjusted Extrusion Multiplier or Flow Rate

Incorrect slicer settings, specifically extrusion multipliers or flow rates, can significantly affect filament output.

Solution: Carefully verify your slicing software settings. Adjust the extrusion multiplier or flow rate. Typically, adjusting the multiplier to 100-105% resolves minor flow inconsistencies. Test and adjust gradually to find the ideal setting for your printer and filament.

4. Filament Feed Issues

If your filament spool isn’t spinning smoothly or the extruder gear isn’t gripping the filament properly, it can cause under-extrusion.

Solution: Check your filament spool holder to ensure filament unwinds freely. Inspect your extruder gear for filament crumbs or debris. Clean it regularly to ensure the gear teeth grip the filament adequately. Also, verify your extruder tension—too loose or too tight can both cause feeding issues. Adjust the tension to allow smooth filament feeding without excessive pressure.

5. Filament Diameter Variations

Filament quality can vary between manufacturers and even batches, causing under-extrusion if the diameter isn’t consistent.

Solution: Measure your filament diameter using precise digital calipers at multiple points along the spool. Enter the average measured diameter into your slicing software for accurate filament flow calculations.

6. Printing Too Fast

Printing at high speeds can cause your extruder to struggle in delivering filament consistently, leading to under-extrusion.

Solution: Reduce your printing speed in the slicing settings. Slowing down your print speed gives your hotend enough time to melt filament properly, improving the overall extrusion consistency.

7. Worn or Damaged PTFE Liner (Bowden Tubes)

If your printer uses a Bowden extruder setup, the PTFE tube can degrade over time, causing friction and restricted filament flow.

Solution: Replace your PTFE tube periodically, especially if you notice friction or resistance when manually pushing filament through. A smooth, friction-free tube drastically improves filament flow.

Preventing Under-Extrusion in the Future

Regular printer maintenance is key to avoiding under-extrusion issues. Keep your nozzle clean, check filament quality regularly, calibrate extrusion settings periodically, and monitor the performance of your printer components.

- Perform regular nozzle inspections and cleanings.

- Store your filament correctly to avoid moisture-related issues.

- Calibrate your printer settings when changing filament types or brands.

- Monitor print results and address any small problems promptly before they escalate.

Conclusion

Under-extrusion can be frustrating, but identifying its cause is usually straightforward. By following these troubleshooting steps and preventative maintenance tips, you’ll enjoy consistent, high-quality 3D prints without the hassles of under-extrusion. Happy printing!

Leave a Reply