Understanding Stringing and Oozing in 3D Printing

If you’ve spent any amount of time with a 3D printer, you’re probably familiar with the frustration caused by stringing and oozing. These pesky imperfections appear as thin, hair-like strands or blobs on your final prints—often causing extra clean-up and reducing the overall quality of your finished models. Thankfully, there are several simple and effective solutions you can implement to minimize or even eliminate these nuisances.

What Causes Stringing and Oozing?

Before we dive into the solutions, it’s important to understand what causes stringing and oozing. Stringing occurs when molten filament oozes from the nozzle as it moves between two points without actively extruding. This typically happens when there’s excess pressure in the nozzle or when temperature settings are too high, allowing filament to flow more freely than intended.

Several key factors can lead to stringing and oozing:

- Excessive Printing Temperature: High temperatures cause the filament to melt more fluidly, leading to uncontrolled filament flow.

- Poor Retraction Settings: Inadequate retraction settings allow filament to seep from the nozzle during non-print movements.

- Travel Speed and Distance: Slow or inefficient travel paths increase the likelihood that filament will leak during movement.

- Moisture in Filament: Filaments, especially PLA and Nylon, can absorb moisture, causing excessive oozing and poor extrusion quality.

Adjust Temperature Settings

One of the most common causes of stringing and oozing is printing at excessively high temperatures. When the filament becomes too fluid, it easily seeps out of the nozzle. To fix this, experiment with slightly lowering your print temperature. If you normally print PLA at 210°C, try reducing it gradually in increments of 5°C to 195-205°C. Always check your filament manufacturer’s recommended temperature range and conduct small test prints to find an optimal balance.

Optimize Retraction Settings

Retraction can significantly reduce or eliminate stringing by pulling filament back into the hotend during travel moves. Important parameters to tweak are:

- Retraction Distance: Adjust by small increments (0.5mm steps). Typically, Bowden-style extruders require higher retraction distances (3-7mm), while direct-drive extruders need less (0.5-2mm).

- Retraction Speed: Faster retraction (30-60 mm/s) helps prevent filament from dripping; however, overly high speeds may cause skipped steps or filament grinding.

Experiment with these settings carefully, running small calibration prints until you find the perfect balance for your machine and filament.

Increase Travel Speed and Adjust Travel Path

Another effective method to minimize stringing is to shorten the time the nozzle spends in non-extrusion travel. Faster travel speeds (up to 150-200 mm/s, depending on printer stability) help reduce oozing. Additionally, enabling options like “Avoid crossing perimeters” or “Combing mode” in your slicer software forces your printer to take the shortest or least problematic route, further preventing unwanted stringing.

Dry Your Filament

Filament moisture content can significantly contribute to stringing and oozing. If your filament has absorbed moisture, even optimal settings won’t eliminate imperfections. To solve this, dry your filament in a dehydrator or oven at low temperatures (PLA typically at 40-50°C for 4-6 hours, Nylon at 60-70°C for 6-8 hours). After drying, store your filaments in airtight containers with desiccant packs to maintain dryness.

Ensure Proper Nozzle Maintenance

A partially clogged or worn-out nozzle can create inconsistent extrusion and exacerbate stringing. Regularly check your nozzle condition and clean or replace it if needed. Keeping the hotend clean and free of filament residues helps maintain smooth extrusion and reduces unwanted oozing.

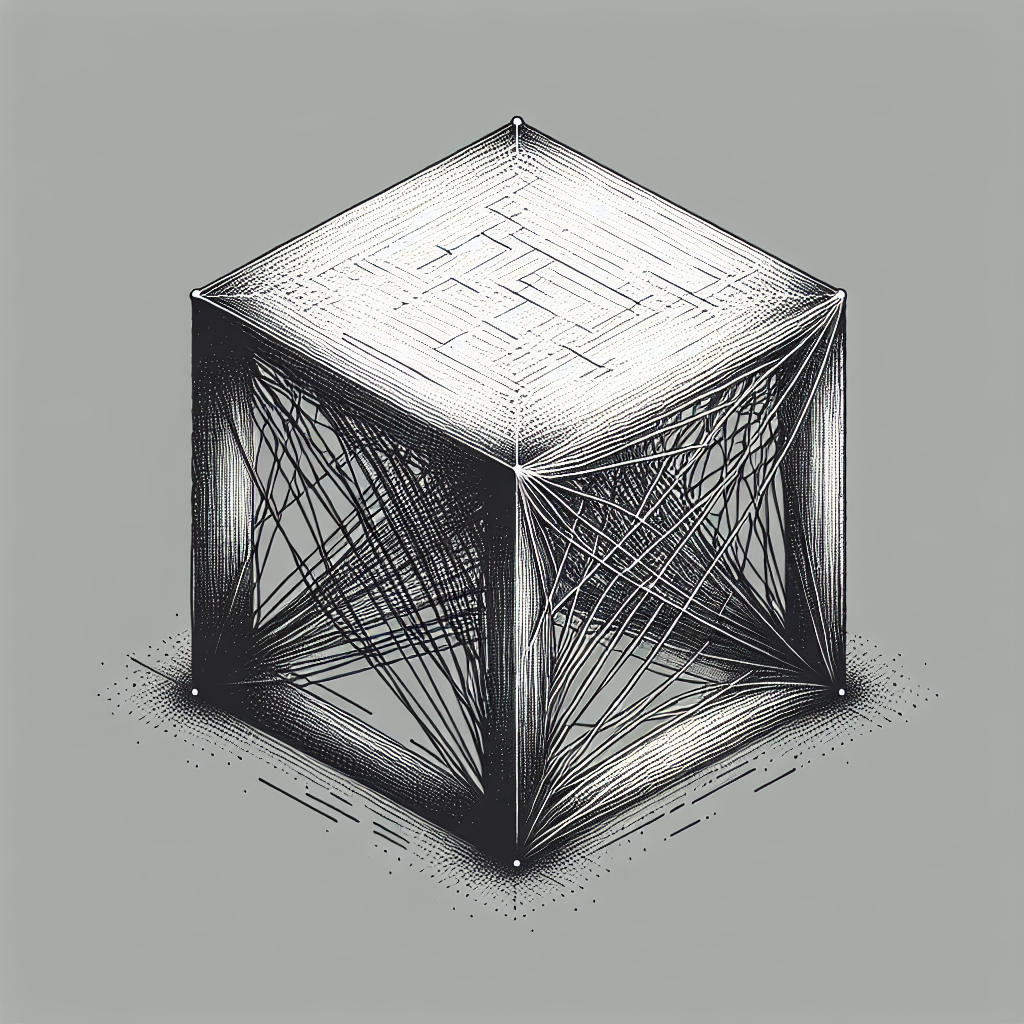

Perform Calibration Tests

The most effective way to diagnose and correct stringing and oozing problems is by performing quick calibration prints. Popular test prints, such as retraction test towers or stringing calibration cubes (available from various online resources), help you quickly and clearly identify the ideal settings for temperature, retraction, speed, and more.

Conclusion

Stringing and oozing can be frustrating, but with a systematic approach, it’s possible to achieve clean, high-quality prints. By carefully adjusting temperatures, refining retraction settings, optimizing travel paths, drying your filament, and maintaining your printer hardware, you’ll eliminate unsightly strings and blobs—leaving you with smooth, professional-quality prints every time.

Leave a Reply