Understanding the Importance of First Layer Calibration

Achieving a flawless first layer is the foundation for every successful 3D print. A poorly calibrated first layer can lead to adhesion problems, warping, or even print failures. From years of hands-on experience, I can attest that investing time in first layer calibration drastically improves print quality and reduces frustration.

Essential Tools for First Layer Calibration

Before you begin, gather these essentials:

- Feeler gauge or standard printer paper (for manual bed leveling)

- Isopropyl alcohol and a lint-free cloth (for cleaning the build surface)

- Your printer’s calibration tools (usually an included wrench or screwdriver)

- Access to your printer’s firmware or control panel

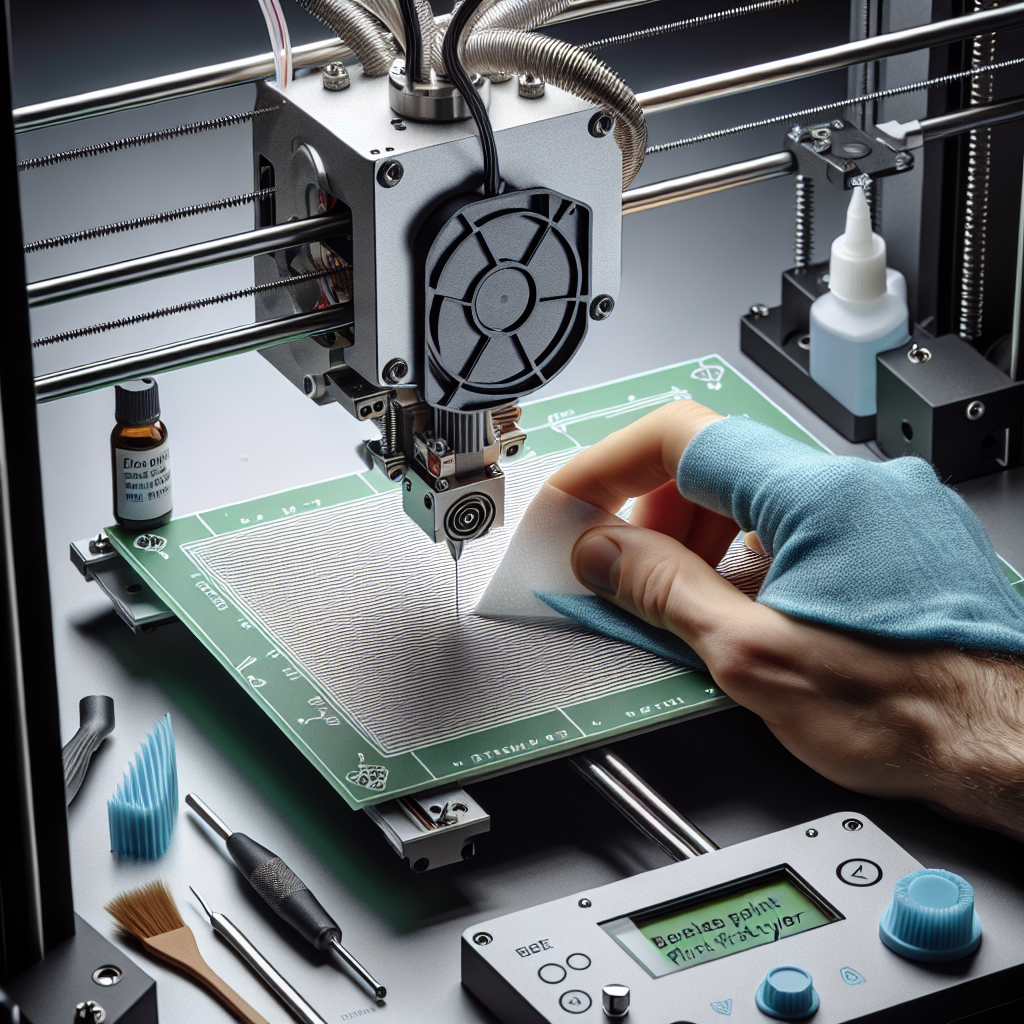

Step 1: Clean Your Print Surface

A clean bed ensures good filament adhesion. Dust, oil from your fingers, or leftover filament can prevent your first layer from sticking. Use isopropyl alcohol and a lint-free cloth to thoroughly clean the print surface before every print.

Step 2: Level the Print Bed

Manual or automatic, bed leveling is crucial. Here’s how to do it manually:

- Home your printer’s axes.

- Move the nozzle to each corner of the bed and the center, lowering it until it nearly touches the bed.

- Insert a piece of paper or a 0.1 mm feeler gauge between the nozzle and bed.

- Adjust the bed height so you feel slight resistance as you move the paper.

- Repeat for all points, checking the center last.

If your printer has auto-bed leveling (ABL), run the ABL routine and double-check the results by printing a test pattern.

Step 3: Set the Correct Z-Offset

The Z-offset determines the nozzle’s exact starting distance from the bed. Too high, and the filament won’t stick; too low, and you risk clogging or gouging the bed.

- Start a print and watch the first layer extrude.

- If the filament lines are thin, nearly transparent, or squished, the nozzle is too close.

- If lines are round and barely touch the bed, the nozzle is too high.

- Adjust the Z-offset in small increments until the filament is slightly squished and lays down evenly.

Step 4: Tune Bed and Nozzle Temperatures

Different materials have specific temperature requirements. Refer to filament manufacturer guidelines, but typical settings are:

- PLA: Bed 50-60°C, Nozzle 190-210°C

- PETG: Bed 70-80°C, Nozzle 220-250°C

- ABS: Bed 90-110°C, Nozzle 230-250°C

Higher bed temperatures improve adhesion, but too high can cause warping or elephant foot (overly squished first layer).

Step 5: Perfect Your Slicer Settings

Adjust these slicer settings for an optimal first layer:

- First Layer Height: A slightly thicker first layer (0.2-0.3mm) helps with adhesion.

- First Layer Speed: Slow down (15-30mm/s) for better accuracy and bonding.

- First Layer Extrusion Width: Increase to 120-140% of the nozzle width for better coverage.

Consider enabling features like “brim” or “raft” if you still struggle with adhesion.

Step 6: Inspect and Test

After calibration, print a simple test pattern (like a single-layer square or a bed-leveling test file). Inspect for:

- Uniform lines: No gaps, overlaps, or thin spots

- Good adhesion: The layer should be difficult to remove but not fused to the bed

- Consistent appearance: No blobs, stringing, or inconsistent extrusion

Make small adjustments as needed and repeat the test until the first layer is perfect.

Troubleshooting Common First Layer Issues

- Warping: Increase bed temperature, add a brim, or use adhesives like glue stick or hairspray.

- Poor adhesion: Lower the nozzle slightly or clean the bed again.

- Nozzle dragging or clogging: Raise the Z-offset and ensure the nozzle is not damaged or dirty.

Final Thoughts

A well-calibrated first layer sets the stage for print success. By methodically cleaning, leveling, adjusting Z-offset, tuning temperatures, and optimizing slicer settings, you’ll ensure your 3D prints start perfectly every time. Remember, even experienced makers revisit these steps regularly for consistent, high-quality results. Happy printing!

Leave a Reply