Introduction to Metal 3D Printing

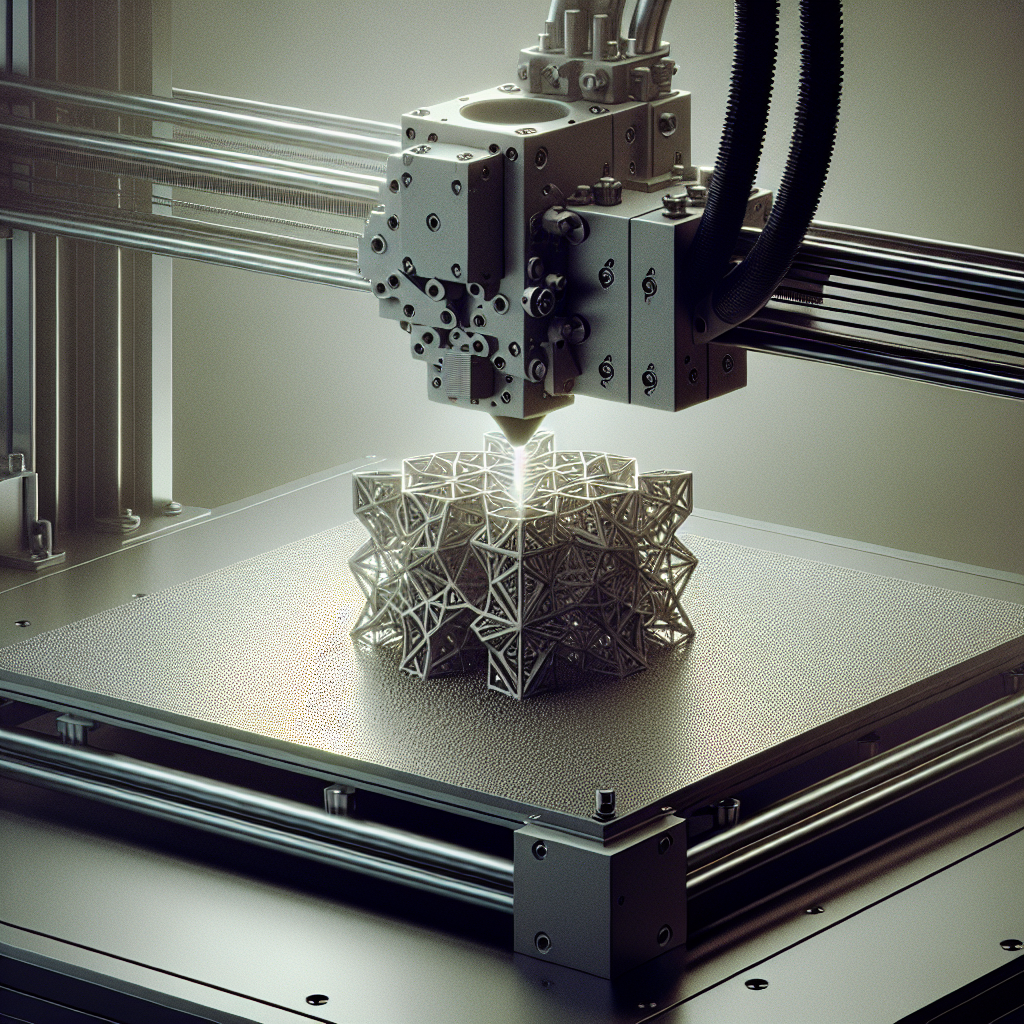

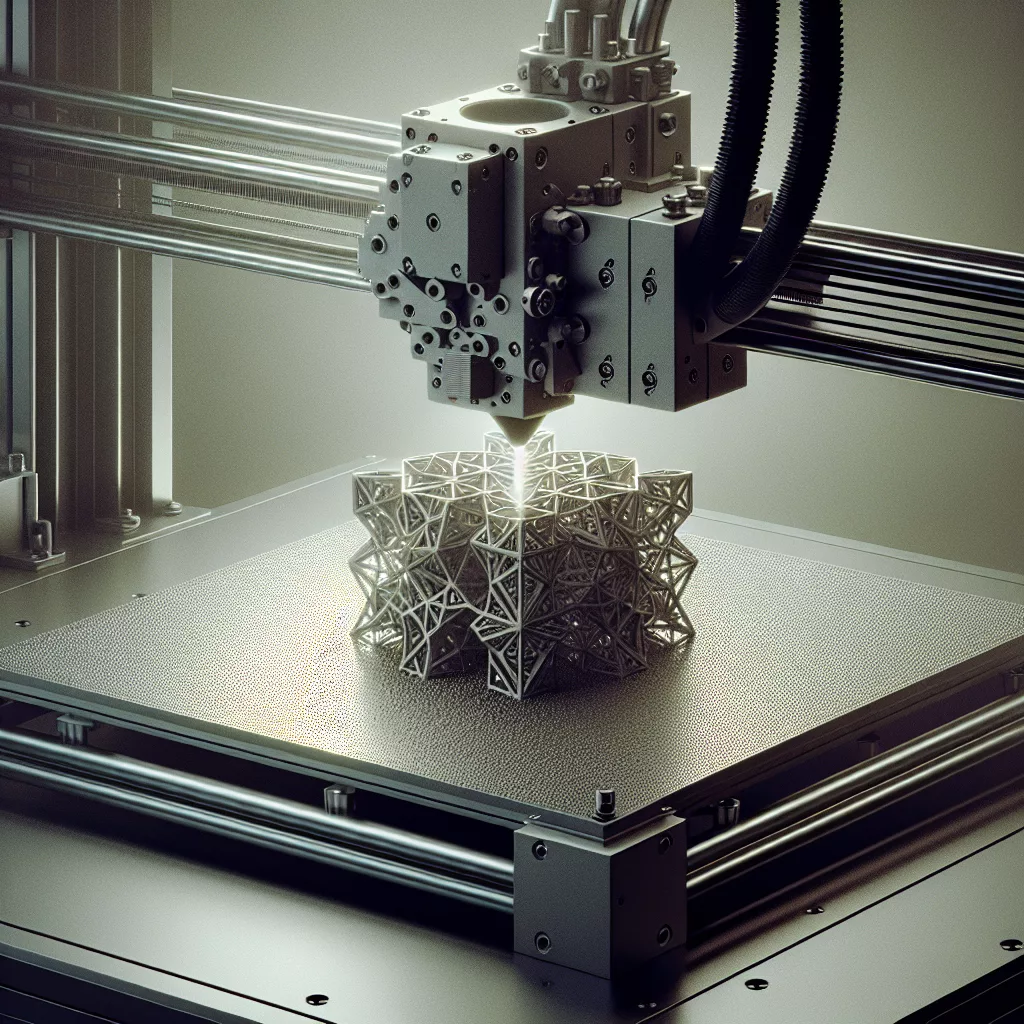

3D printing has revolutionized manufacturing, prototyping, and even hobbyist projects in recent years. From plastic toys and functional prototypes to automotive components and medical implants, this technology has significantly evolved. But one question that continues to intrigue novices and experts alike is—can you 3D print metal?

The answer is a resounding yes! Metal 3D printing, also known as additive manufacturing, has become a pivotal advancement that allows us to create complex geometry components with intricate details that were previously impossible or prohibitively expensive using traditional manufacturing techniques. Let’s dive deeper into metal 3D printing and explore everything you need to know.

How Does Metal 3D Printing Work?

Metal 3D printing typically involves adding successive layers of metal powder, fused together layer by layer using high-powered lasers or electron beams. This process, known as Powder Bed Fusion (PBF), includes specific technologies such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM).

Another approach to metal 3D printing involves Metal Binder Jetting technology. In this case, a liquid binding agent selectively joins metal powder layers. After printing, the parts undergo post-processing steps like sintering and infiltration to strengthen and finalize the metal object.

What Metals Can You 3D Print?

A wide range of metals can be effectively 3D printed, including:

- Stainless Steel: Commonly used due to its durability, corrosion resistance, and mechanical strength.

- Titanium: Widely utilized in aerospace, automotive, and medical industries due to its lightweight properties and biocompatibility.

- Aluminum: Ideal for lightweight, high-strength applications in aerospace, automotive, and consumer products.

- Cobalt-Chrome: Popular in medical implants and dental applications due to excellent biocompatibility and strength.

- Copper and Bronze: Useful for electrical conductivity, decorative purposes, and artistic projects.

- Nickel-based alloys (Inconel): Often used for high-temperature aerospace and automotive applications.

- Precious Metals (Gold, Silver): Primarily used in jewelry making and specialized industrial applications.

As technology advances, researchers are continually adding more alloys and specialty metals to this list, expanding the potential applications and industries benefiting from metal additive manufacturing.

Advantages of Metal 3D Printing

Metal 3D printing offers numerous advantages over traditional manufacturing methods:

- Complexity & Customization: Easily build highly intricate geometries, internal channels, and complex features impossible to manufacture traditionally.

- Reduced Weight: The ability to create hollow structures and optimized topology drastically reduces part weights—a critical factor in aerospace and automotive applications.

- Rapid Prototyping: Speed up development cycles by quickly iterating designs and testing functional metal prototypes.

- Cost Efficiency: Low-volume production, customization, and design revisions are more economical compared to traditional manufacturing methods.

- Improved Performance: Metal 3D printing provides optimized designs with improved mechanical properties and performance tailored specifically for applications.

Limitations and Challenges of Metal 3D Printing

Despite its many benefits, metal 3D printing is not without challenges:

- High Cost: Metal 3D printers and materials can be significantly more expensive than plastic printers and traditional machining, making initial investments substantial.

- Surface Roughness: Printed parts often require post-processing such as machining, polishing, or grinding to achieve smooth finish surfaces.

- Porosity and Internal Defects: Due to the layered and powder-based nature, metal prints occasionally contain microscopic porosity or defects, requiring thorough inspection and quality control.

- Limited Build Volume: Most metal 3D printers have limited build sizes, restricting the printing of large-scale components.

- Skilled Operation: Operating metal 3D printers demands expertise, technical training, and detailed post-processing knowledge.

Applications of Metal 3D Printing

The applications of metal 3D printing span numerous industries, including:

- Aerospace: Lightweight, optimized turbine blades, engine components, and structural parts.

- Automotive: Customized performance parts, lightweight chassis components, and rapid prototyping.

- Medical & Dental: Personalized implants, prosthetics, surgical tools, and dental crowns.

- Jewelry & Fashion: Highly detailed, customized jewelry designs made from precious metals.

- Manufacturing: Tooling, fixtures, jigs, molds, and complex, customized machinery components.

Should You Invest in Metal 3D Printing?

Deciding whether to invest in metal 3D printing depends on your industry, budget, application requirements, and production volume. If your business involves customized, highly complex metal parts, rapid prototyping, or low-volume production, metal 3D printing could significantly enhance productivity and innovation capabilities.

However, if you predominantly require simple metal components, high-volume production, or have budget constraints, traditional manufacturing methods might remain the most cost-effective route.

Conclusion

Yes, you absolutely can 3D print metal, and the technology is rapidly evolving to become more accessible and reliable. Metal 3D printing opens doors to incredible innovation, enabling designers, engineers, and manufacturers to create parts previously impossible to produce and to push the boundaries of what’s possible.

Understanding the benefits, limitations, and available applications ensures your decision to adopt metal 3D printing technology will be informed and strategic, helping your projects reach new levels of quality, performance, and innovation.

Leave a Reply