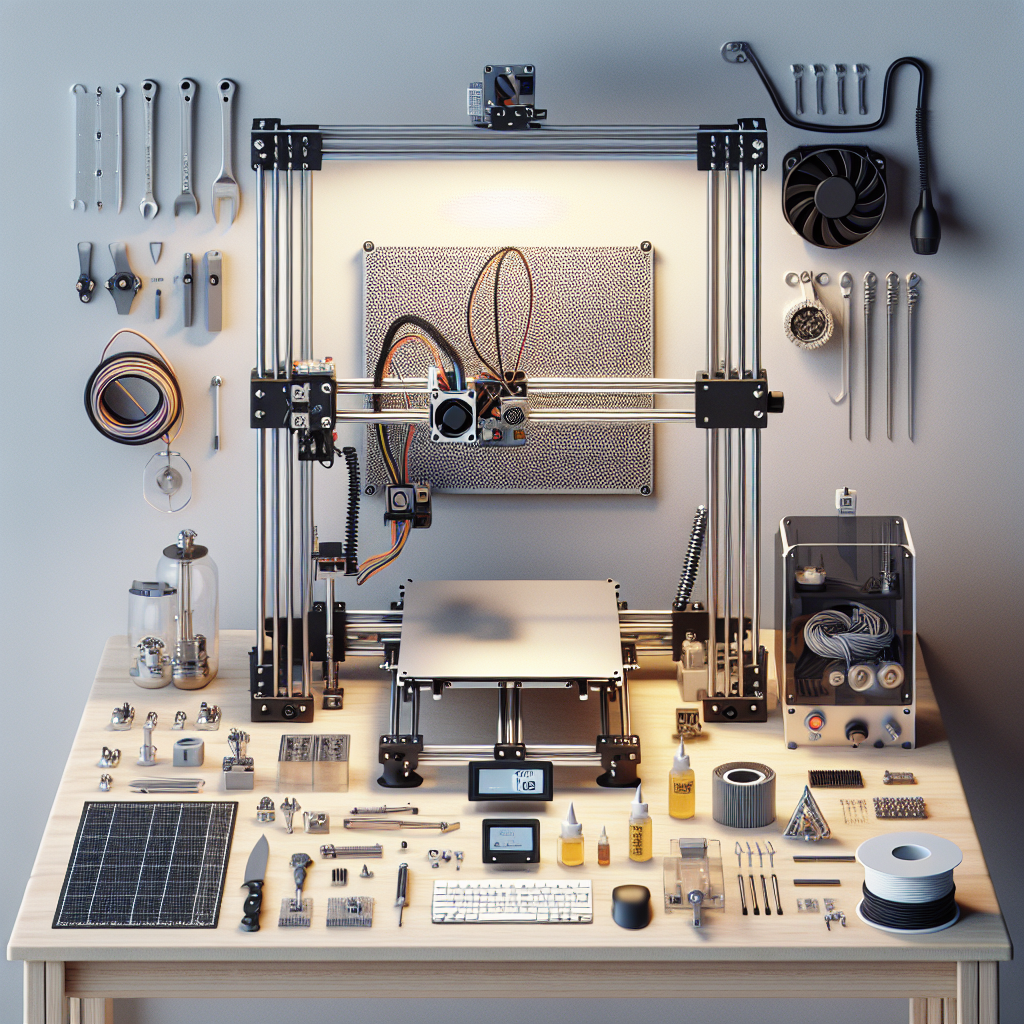

Introduction: Transforming Your Budget 3D Printer

If you’ve snagged a budget 3D printer, congratulations! Entry-level machines like the Ender 3, Anycubic Kobra, or Prusa MINI SE are incredibly capable, but they often leave room for improvement. The good news? With targeted upgrades, you can elevate your printer to rival even high-end machines in print quality, reliability, and user experience—without breaking the bank. Drawing from years of hands-on tinkering, here’s my expert guide to the best upgrades to make your budget 3D printer truly high-end.

1. Upgrade to an All-Metal Hotend

Stock hotends on budget printers are often limited to lower temperatures, restricting the filament types you can print (such as ABS or PETG). Upgrading to an all-metal hotend (like the E3D V6 or Micro Swiss) means you can safely print at higher temperatures, opening the door to more advanced materials and reducing the risk of PTFE tube degradation. This upgrade dramatically improves print consistency and unlocks new material possibilities.

2. Install an Auto Bed Leveling (ABL) Sensor

Manual bed leveling can be frustrating and inconsistent. Adding an auto bed leveling probe (such as BLTouch or CR Touch) automates this process, ensuring a perfect first layer every print. Not only does it save time, but it also improves adhesion and reduces failed prints. This is a game-changing upgrade that bridges the gap between budget and premium printers.

3. Upgrade to a Glass or PEI Build Surface

The print bed material affects adhesion and ease of print removal. The classic upgrade is a tempered glass bed, providing a perfectly flat surface and a glossy bottom finish. Alternatively, magnetic PEI sheets offer excellent adhesion for a wide range of filaments and make removing prints a breeze. Both options outperform the stock build surfaces found on most entry-level printers.

4. Add Silent Stepper Motor Drivers

Budget printers are known for their noise—often from stock stepper drivers. Upgrading to silent drivers, such as TMC2208 or TMC2209, quiets the stepper motors dramatically, making your printer suitable for home, office, or bedroom environments. The improvement in quality of life is immediate, and you’ll appreciate the near-silent operation.

5. Upgrade Cooling Fans and Ducts

Effective part cooling is crucial for sharp overhangs, bridges, and overall print quality. Many budget printers cut costs with weak fans or poorly designed ducts. Upgrading to high-quality fans (like Noctua or Sunon) and optimized cooling ducts (such as Petsfang or Hero Me) ensures your prints are cooled evenly, resulting in cleaner, crisper results.

6. Switch to a Direct Drive Extruder

Bowden setups are common on budget printers, but they can struggle with flexible filaments and require higher retraction settings. Upgrading to a direct drive extruder (such as the Micro Swiss Direct Drive or Bondtech kits) delivers better extrusion control, especially for TPU and other flexibles, and reduces the risk of stringing and jams.

7. Upgrade Your Mainboard

A modern mainboard with a more powerful processor, better thermal management, and silent stepper drivers brings both performance and features. Boards like the BigTreeTech SKR or Creality 4.2.7 support advanced firmware (like Marlin 2.0), filament runout detection, and power recovery—features usually found only on premium printers.

8. Improve Frame Rigidity

Vibration and wobble are the enemy of high-quality prints. Consider adding frame bracing kits, swapping plastic parts for metal, or even printing your own reinforcement brackets. A rigid frame minimizes Z-banding, ghosting, and layer misalignment, leading to noticeably sharper prints.

9. Add OctoPrint or Klipper for Wireless Control

Take your 3D printer into the future by adding a Raspberry Pi running OctoPrint or Klipper. This allows wireless monitoring, webcam time-lapses, plugin support, and advanced control right from your phone or computer. For advanced users, Klipper brings faster print speeds and smoother motion.

10. Invest in Quality Consumables

Finally, don’t overlook the impact of premium filament and lubricants. High-quality PLA, PETG, or specialty filaments can make a visible difference in print quality. Regularly lubricate rods and lead screws with the correct grease to reduce wear and maintain accuracy.

Conclusion: Your Path to High-End Prints

With these upgrades, your budget 3D printer can rival machines costing several times more. Start with the upgrades that address your main pain points—reliability, noise, print quality, or material capability—and expand as your skills and needs grow. 3D printing is a journey, and each tweak brings you closer to professional-grade results without a professional-grade price tag.

Happy printing—and may your upgrades bring you perfect layers and endless creativity!

Leave a Reply