Introduction to 3D Printing on Fabric

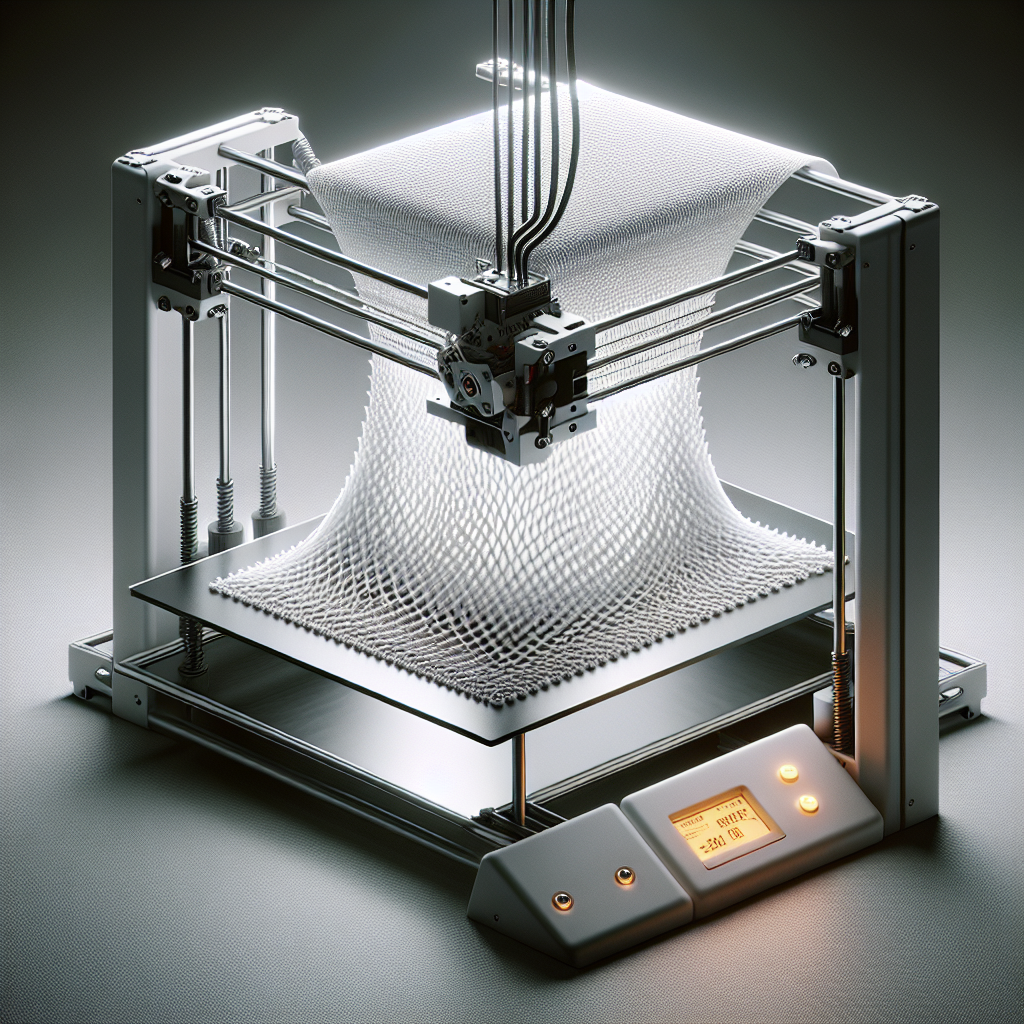

The fusion of 3D printing technology with textiles has unlocked a new frontier in fashion and wearable design. Printing on fabric and creating 3D printed clothing is no longer just a concept for runway shows; makers and designers now have access to the tools, materials, and know-how to bring these futuristic garments to life. In this article, I’ll share practical insights and proven techniques from my years in the 3D printing world to help you print on fabric and craft your own 3D printed clothing.

Why 3D Print on Fabric?

Traditional garment construction relies on sewing, cutting, and assembling fabrics. 3D printing, on the other hand, enables the creation of complex geometries, custom patterns, and unique textures that would be nearly impossible with conventional methods. Whether you’re aiming for decorative embellishments, flexible armor-like panels, or fully integrated garments, 3D printing on fabric opens a world of creative possibilities.

Choosing the Right Fabric

Not all fabrics are created equal when it comes to supporting 3D printed elements. The ideal fabric for 3D printing is:

- Stable and Non-Stretchy: Fabrics like cotton, polyester, and canvas provide a stable surface for printing. Highly stretchy fabrics can distort during printing, leading to adhesion or warping issues.

- Thin but Not Sheer: Thin fabrics allow the 3D print to bond well, but excessively sheer materials may not hold the print securely.

- Heat Resistant: Since 3D printing involves heat, opt for fabrics that can withstand the printing temperature of your chosen filament.

Selecting the Right Filament

The most common filaments for printing on fabric include:

- PLA: Easy to print and adheres well to fabric, but it’s relatively stiff and less flexible.

- TPU/TPE: Flexible filaments like TPU or TPE are ideal for wearables, allowing the 3D print to bend and move with the fabric.

- ABS: Possible but less common due to higher print temperatures and weaker fabric adhesion.

Test your filament-fabric combination before embarking on a large project.

Preparing the Fabric for Printing

Preparation is key for successful adhesion:

- Clean and Iron: Ensure your fabric is clean and wrinkle-free. Iron it flat before placing it on your print bed.

- Secure to Print Bed: Use a temporary adhesive (like a glue stick, painter’s tape, or spray adhesive) to attach the fabric smoothly to the print bed. Avoid bunching or stretching.

- Frame or Clamp: For larger prints, use a simple frame or clamps at the edges to keep the fabric taut during printing.

Setting Up the 3D Printer

A standard FDM (Fused Deposition Modeling) printer is suitable for printing on fabric. Here’s what to keep in mind:

- Nozzle Height: Adjust the Z-offset so the nozzle is just above the fabric surface.

- Bed Temperature: Set the bed temperature according to your filament. For PLA on cotton, 50–60°C is often optimal.

- Print Speed: Use a slower print speed (20–35 mm/s) for accurate deposition and better adhesion.

Design Tips for 3D Printed Clothing

Designing wearable 3D prints is a balance between aesthetics, comfort, and functionality.

- Flexible Structures: Use lattice, mesh, or chainmail patterns to keep the print lightweight and flexible.

- Attachment Points: Design features like snap-fits, buttonholes, or integrated seams for connecting printed parts to fabric or other prints.

- Test Small: Print small test patches before committing to a large print.

Printing Process

- Secure the prepared fabric to your print bed.

- Start the print and monitor the first few layers closely to ensure good adhesion.

- If the print lifts off or shifts, pause and reapply adhesive or reflatten the fabric.

- Once printing is complete, gently remove the fabric from the bed. Trim away excess threads or filament as needed.

Finishing Touches

Depending on your design, you may want to:

- Sew or Glue: Reinforce the edges of the print or attach additional fabric backing.

- Dye or Paint: Add color to the fabric or printed elements.

- Wash Carefully: Hand wash and air dry to preserve both fabric and print, especially if you used flexible filaments.

Inspiration: Examples of 3D Printed Clothing

From avant-garde fashion to functional sportswear, 3D printing on fabric is making waves. Designers like Iris van Herpen and Danit Peleg have showcased stunning 3D printed dresses and jackets on world stages. Makers at home are experimenting with cosplay armor, customizable sports pads, and even everyday t-shirts with embedded patterns.

Conclusion

Printing on fabric and creating 3D printed clothing is a rapidly evolving field, merging material science, digital design, and creative fashion. By carefully selecting materials, preparing your fabric, and optimizing your print settings, you can craft one-of-a-kind garments that stand out. Whether you’re a designer, maker, or hobbyist, the world of wearable 3D prints awaits your imagination.

Leave a Reply