Understanding Support Material in 3D Printing

Support material is an essential aspect of FDM (Fused Deposition Modeling) and some resin-based 3D printing processes. These temporary structures uphold overhangs, bridges, and intricate geometries as the object prints. However, supports not only add extra filament or resin usage, but they also increase print time and post-processing work, often resulting in unnecessary waste. Reducing support material waste saves money, time, and environmental resources.

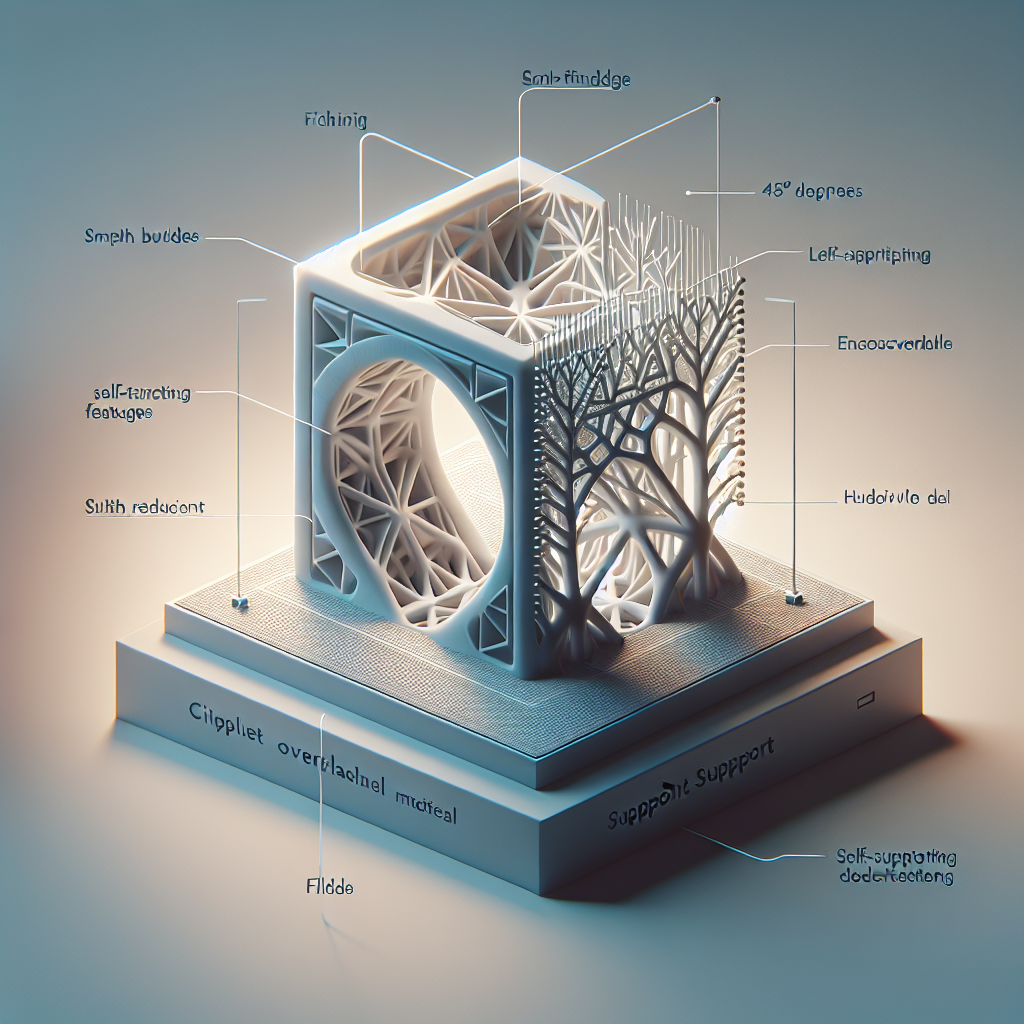

Design for Reduced Supports

A significant way to minimize support usage starts at the design stage. Here are practical strategies:

- Optimize Overhang Angles: Most FDM printers handle overhangs up to 45 degrees without support. Adjust your model’s angles where possible to stay within this limit.

- Split Complex Models: Break your design into multiple parts that can be printed flat or with minimal overhangs, then reassemble afterward.

- Integrate Self-Supporting Features: Arches, chamfers, and fillets can replace unsupported horizontal bridges, reducing or eliminating the need for supports.

- Use Custom Supports: In some CAD programs, you can design your own supports that are easier to remove and use less material than auto-generated ones.

Optimize Slicer Settings for Minimum Support

Slicer software offers powerful options to control support generation. Tweak these key settings to reduce waste:

- Support Density: Lowering the density reduces material use. Start with 10-15% unless your model needs more robust supports.

- Support Pattern: Patterns like lines or zig-zag are easier to remove and use less material than grid or concentric patterns.

- Support Placement: Use “Touching Buildplate” rather than “Everywhere” if your model allows, so supports are only generated where absolutely necessary.

- Support Interface Layers: Decrease interface layers for easier removal and less waste, but be careful not to compromise surface finish.

Leverage Advanced Support Technologies

Modern slicers and multi-material printers offer advanced ways to further cut support waste:

- Tree Supports: Available in slicers like Cura, tree supports branch out organically and conform closely to the object, using far less material than traditional supports.

- Dissolvable Supports: Dual-extruder printers can use materials like PVA or HIPS for supports. While this doesn’t reduce waste, it allows for easier removal and recovery of complex prints, which can reduce failed prints overall.

- Adaptive Supports: Some slicers use algorithms to only place supports where they’re structurally needed, instead of blanketing large areas.

Recycle or Reuse Support Material

Despite best efforts, some support waste is inevitable. Here’s how to give it a second life:

- Filament Recycling: Collect PLA, ABS, or PETG supports and consider using a filament recycler to create new spools. This requires investment, but is great for high-volume printers.

- Upcycle Small Supports: Use clean support scraps for prototyping, testing fit, or even creative projects like art, keychains, or educational aids.

- Proper Disposal: If recycling isn’t an option, dispose of supports according to local regulations. PLA is compostable in industrial facilities, while ABS and PETG should be recycled if possible.

Conclusion: Smarter Printing, Less Waste

Reducing support material waste in 3D printing comes down to a combination of smart design, savvy slicer settings, and embracing new support technologies. With a thoughtful approach, you’ll not only save money and time but also contribute to a more sustainable 3D printing ecosystem. Every change—no matter how small—makes a difference toward cleaner, more efficient additive manufacturing.

Leave a Reply