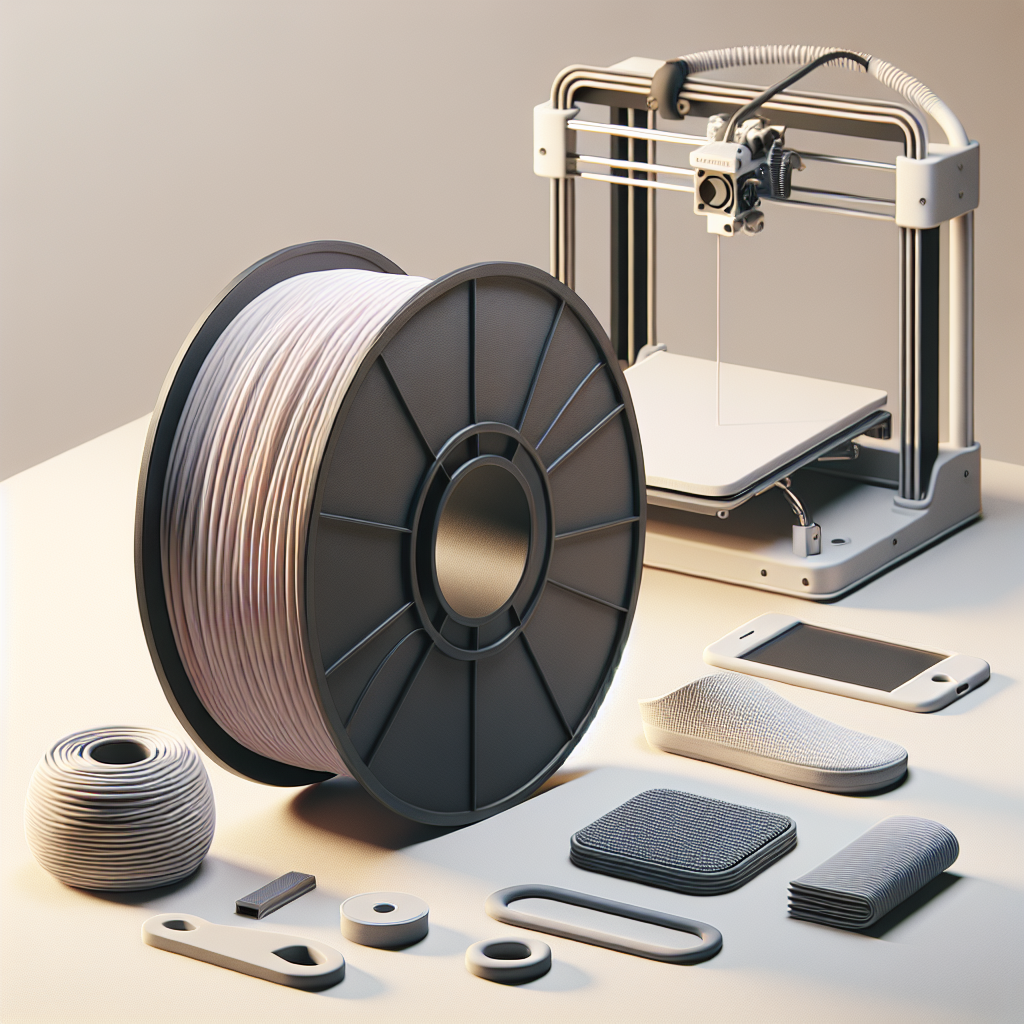

Understanding Flexible Filaments in 3D Printing

Flexible filaments have become a staple material for makers and professionals who demand more than just rigid plastics. Ideal for projects requiring elasticity, impact resistance, and unique tactile qualities, flexible filaments open the door to applications such as gaskets, phone cases, wearables, tires, and even robotics parts. But not all flexible filaments are created equal—their chemistry, printability, and performance can vary dramatically.

Key Qualities of High-Performance Flexible Filaments

When selecting a flexible filament for demanding applications, consider these crucial properties:

- Shore Hardness – This scale measures how hard or soft the filament is. Lower numbers (e.g., Shore A 85) mean softer, more elastic prints.

- Printability – How easily the filament feeds through your printer, especially in Bowden extruders, and at what speeds.

- Layer Adhesion & Durability – Flexibles must bond well between layers to withstand bending and stretching without delamination.

- Chemical & Abrasion Resistance – Important for industrial or outdoor use.

- UV and Weather Resistance – Necessary for functional prototypes and end-use parts exposed to the elements.

Top Types of Flexible Filaments

TPU (Thermoplastic Polyurethane)

TPU is by far the most popular flexible filament type. With Shore hardness typically ranging from 85A to 95A, it balances flexibility with strength and abrasion resistance. It prints relatively easily—even on most direct-drive and some Bowden printers—and is available in a wide array of colors and transparencies.

Best For: Wearables, phone cases, RC tires, seals, and gaskets.

Recommended Brands: Prusa TPU, NinjaTek Cheetah, Overture TPU, and SainSmart TPU.

TPE (Thermoplastic Elastomer)

TPE is a broad category, but in 3D printing, it often refers to very soft, rubbery filaments. It’s generally more elastic and stretchable than TPU, but can be trickier to print due to its softness.

Best For: Projects needing extreme flexibility—think soft grips, flexible toys, or shock absorbers.

Recommended Brands: NinjaFlex, Filaflex, and Polymaker PolyFlex.

TPA (Thermoplastic Polyamide)

TPA blends the flexibility of rubbers with the chemical resistance of polyamides (nylons). TPA offers superb abrasion resistance and is less prone to cracking or breaking under repeated stress.

Best For: Industrial use, bushings, and parts exposed to automotive fluids.

Recommended Brands: NinjaTek Armadillo, Recreus Filaflex.

Tips for Printing Flexible Filaments

- Direct Drive Extruder: Flexibles work best on direct-drive setups, as the shorter path prevents filament buckling.

- Slow Down: Print speeds of 15–40 mm/s yield better results.

- Reduce Retraction: Excessive retraction can cause jams; tune for minimal movement.

- Print Bed Preparation: Use PEI, glue stick, or painter’s tape for strong adhesion; watch for warping on large prints.

- Consistent Feeding: Keep filament dry and feed path smooth to avoid jams.

Comparing Top Flexible Filament Brands

| Brand | Material | Shore Hardness | Printability | Special Features |

|---|---|---|---|---|

| NinjaFlex | TPE | 85A | Moderate (slow speeds) | Ultra-flexible, highly elastic |

| SainSmart TPU | TPU | 95A | Easy | Wide color range, affordable |

| PolyMaker PolyFlex | TPU | 90-95A | Easy | Consistent quality, minimal warping |

| Recreus Filaflex | TPE/TPA | 82A | Challenging (direct drive recommended) | Extreme stretch, multiple durometers |

| NinjaTek Cheetah | TPU | 95A | Easy, even for Bowden | Fastest flexible filament |

Applications Showcasing High-Performance Flexibles

- Prototyping Soft Robotics: Flexibles are ideal for pneumatic actuators and joints.

- Automotive Seals & Grommets: Chemical-resistant TPA and high-durometer TPU excel here.

- Protective Cases: TPU provides shock absorption for electronics and wearables.

- Customized Footwear & Insoles: Flexible, skin-safe filaments allow for truly tailored comfort.

Conclusion: Choosing the Right Flexible for Your Needs

Selecting the best flexible filament depends on your specific project requirements—flexibility, strength, chemical resistance, and printability all play key roles. For most users, TPU offers the best balance, but TPE and TPA filaments push the limits for specialized, high-performance applications. With proper printer setup and the right brand, flexible filaments will elevate your 3D printing projects to new levels of durability and creativity.

Leave a Reply