The Evolution of 3D Printing in Space

3D printing, also known as additive manufacturing, has revolutionized terrestrial industries, but its true potential may be realized off-planet. The unique challenges of space exploration—such as extreme isolation, limited payloads, and the need for rapid innovation—make 3D printing an ideal solution for building, repairing, and maintaining complex equipment beyond Earth’s atmosphere. As we stand on the cusp of a new era in space travel and habitation, let’s explore how 3D printing is shaping the future of space exploration.

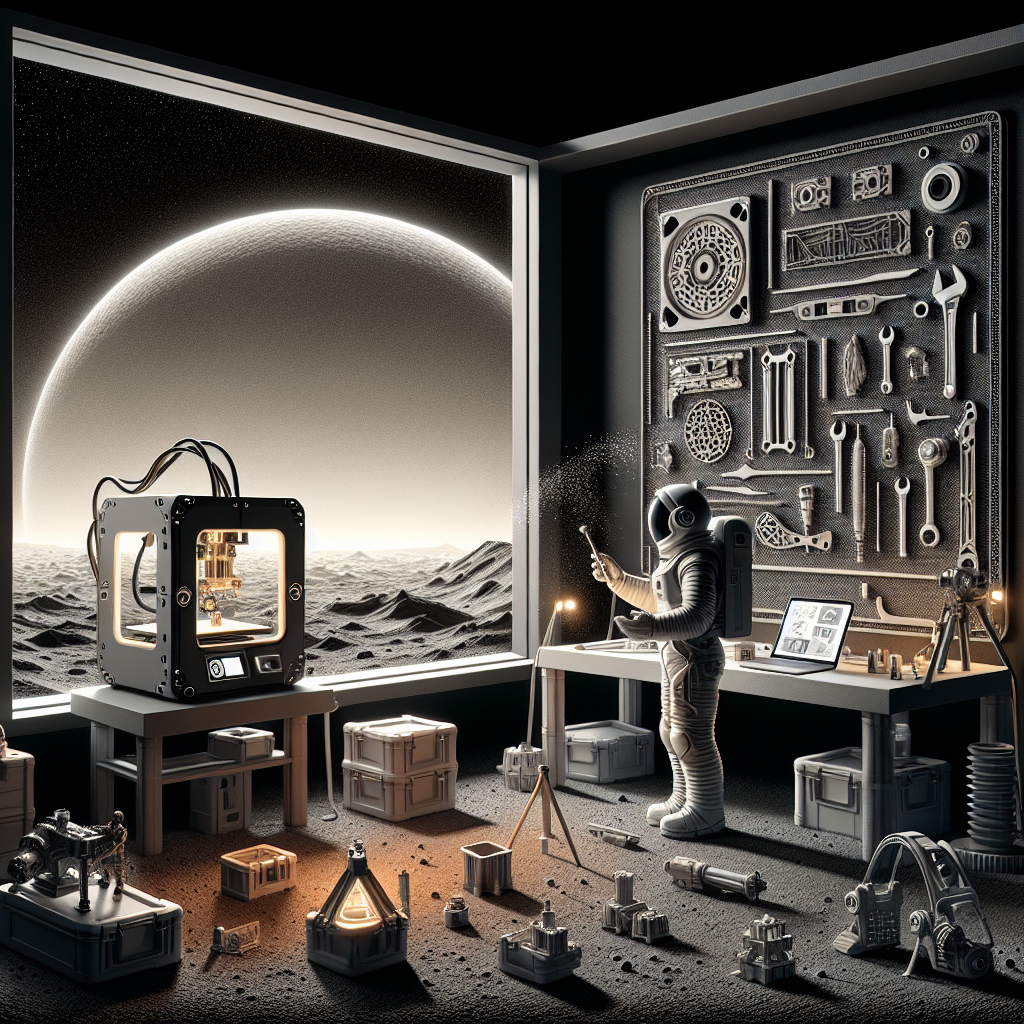

Reducing Payloads: Printing What We Need, When We Need It

One of the greatest constraints in space missions is payload mass. Every kilogram sent into orbit dramatically increases launch costs. Traditionally, astronauts had to carry every tool, part, and spare component they might need. With 3D printing, this paradigm is shifting. Instead of packing spares for every conceivable failure, missions can now bring digital files and raw materials. If a part breaks, astronauts can print a replacement on demand, drastically reducing the mass and volume required for mission-critical components.

On-Demand Manufacturing and Repairs

Unexpected failures in space can be catastrophic or, at minimum, mission-limiting. The International Space Station (ISS) has already demonstrated 3D printing’s value by fabricating custom tools and replacement parts in orbit. In 2014, the first 3D printer in space produced a ratchet wrench for astronauts, based on a digital model sent from Earth. The ability to manufacture components on demand reduces reliance on resupply missions, making long-duration missions safer and more sustainable.

Utilizing In-Situ Resources: Printing from Local Materials

Perhaps the most exciting frontier is in-situ resource utilization (ISRU). Instead of hauling all raw materials from Earth, future explorers can harvest and process local materials—regolith (lunar or Martian soil), for example—to print habitats, landing pads, and other critical infrastructure. Several prototypes have already demonstrated the feasibility of using lunar and Martian soil simulants as feedstock for 3D printers. This approach will be vital for establishing and expanding off-world colonies.

Building Habitats and Infrastructure on the Moon and Mars

As international space agencies and private enterprises plan for lunar bases and Mars missions, 3D printing will be essential for constructing habitats capable of shielding crews from radiation, micrometeoroids, and extreme temperatures. Robotic 3D printers can work autonomously to fabricate shelters before humans arrive, reducing risk and preparation time. NASA, ESA, and companies like ICON are already experimenting with large-scale 3D printers that use regolith simulants to build durable, airtight structures.

Advancing Scientific Research and Innovation

Space environments are dynamic and unpredictable, requiring constant innovation. 3D printing empowers astronauts to prototype new tools and scientific instruments on the fly. This flexibility accelerates research and allows astronauts to adapt to unforeseen challenges or pursue new opportunities without waiting for shipments from Earth.

Bioprinting and Medical Applications

Long-term missions will also require new approaches to healthcare. Bioprinting—3D printing using living cells—could enable the on-demand fabrication of tissues, implants, or even organs, using the patient’s own cells. Research is already underway to explore how microgravity can enhance the printing of complex biological structures, potentially opening new frontiers in regenerative medicine for both space and Earth applications.

Challenges and the Road Ahead

Despite its promise, 3D printing in space faces significant technical challenges. Printers must withstand radiation, vibration, and vacuum. Material feedstocks need to be stabilized for long periods. Quality control and consistency are critical—especially for mission-critical components. Advances in material science, remote monitoring, and robotic operation will be essential to fully realize the potential of additive manufacturing in space.

Conclusion: A New Era of Exploration

3D printing is more than just a technology—it’s a paradigm shift for space exploration. It enables adaptability, self-sufficiency, and sustainability in environments where resupply is impossible. As we prepare for missions to the Moon, Mars, and beyond, 3D printing will undoubtedly be at the core of our efforts to live, work, and thrive off Earth. The future of space exploration will quite literally be built layer by layer.

Leave a Reply