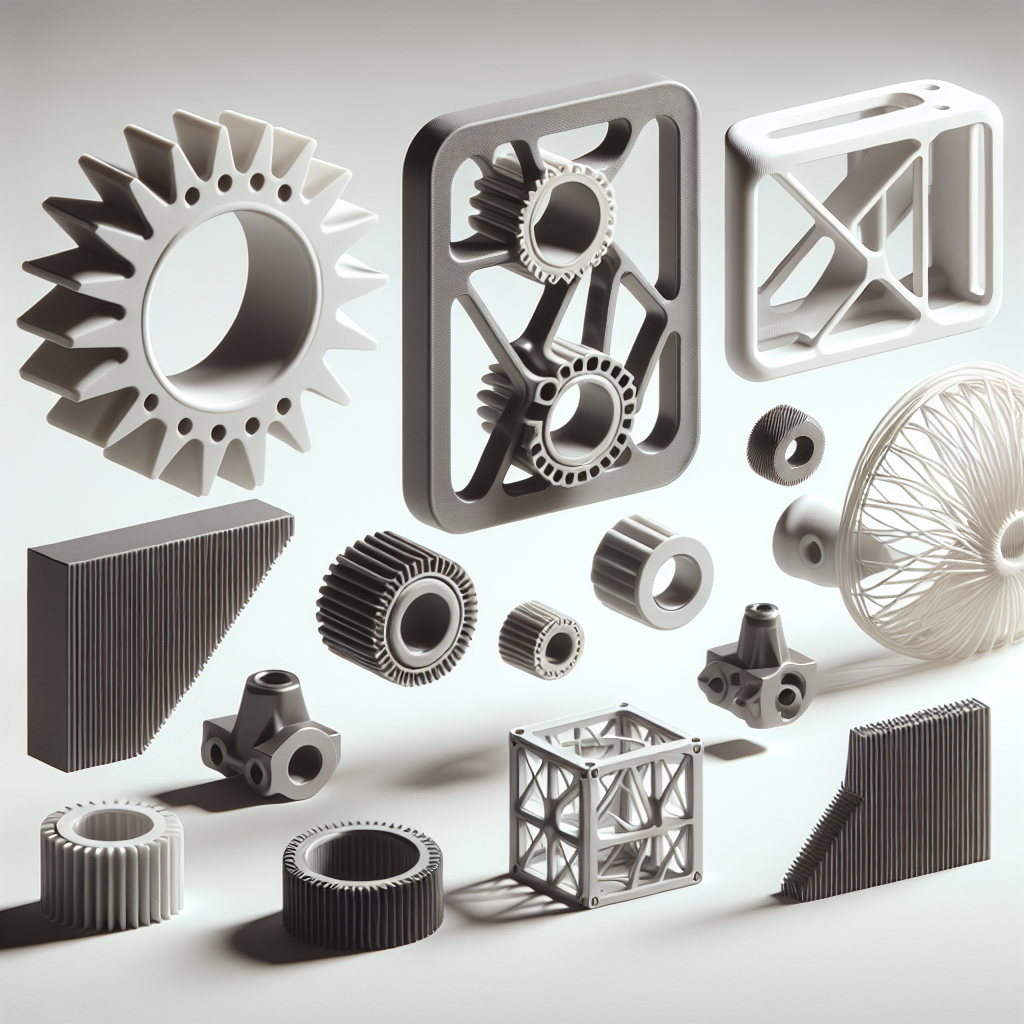

Understanding High-Strength Filaments in 3D Printing

When it comes to 3D printing parts that must withstand significant stress, traditional PLA just doesn’t cut it. High-strength 3D printing filaments open new possibilities for functional prototypes, end-use parts, tooling, and more. Selecting the right filament for your application can mean the difference between a successful build and a brittle disappointment. Drawing on years of hands-on experience, let’s explore the top contenders for high-strength 3D printing, how they compare, and practical tips for getting the best results.

Top High-Strength Filament Options

1. Polycarbonate (PC)

Polycarbonate is widely regarded as one of the toughest 3D printing filaments available. With an impressive tensile strength (up to 70 MPa) and high impact resistance, PC is well-suited for functional, engineering-grade parts such as gears, brackets, and enclosures. Its heat resistance (up to 110°C) also makes it ideal for components exposed to higher temperatures.

Printing considerations: Polycarbonate requires high nozzle (260–310°C) and bed temperatures (90–110°C), excellent bed adhesion (use a PEI sheet or glue stick), and an enclosure to prevent warping. Some brands offer PC blends that are easier to print at slightly lower temperatures.

2. Nylon (Polyamide)

Nylon offers an impressive balance of strength, flexibility, and durability. It excels at making parts that need to withstand repeated mechanical stress, such as hinges, bushings, and functional prototypes. Nylon is also resistant to chemicals and abrasion.

Printing considerations: Nylon is hygroscopic, meaning it readily absorbs moisture from the air, which can ruin prints. Always dry nylon filament before printing. It prints at 240–270°C with a heated bed (70–90°C). An enclosure helps minimize warping, and using a glue stick or special adhesion sheet improves bed adhesion.

3. Carbon Fiber Reinforced Filaments

Carbon fiber-infused filaments are available with various base polymers, including PLA, PETG, Nylon, and Polycarbonate. The addition of chopped carbon fibers significantly increases rigidity and strength while reducing weight. Carbon fiber nylon (PA-CF) is particularly popular for strong, lightweight components like drone frames and structural parts.

Printing considerations: These filaments are abrasive, so use a hardened steel or ruby nozzle. Follow printing recommendations for the base polymer, but expect stiffer, more dimensionally stable prints. Keep the filament dry and consider an enclosure for the best results.

4. PETG and PETG Blends

PETG is a robust, user-friendly filament that bridges the gap between PLA and ABS. It’s more impact-resistant than PLA and less brittle, making it a great choice for moderately high-strength applications and outdoor use. PETG blends with carbon fiber or other additives can further improve strength and rigidity.

Printing considerations: PETG prints at 230–250°C with a heated bed (70–85°C). It’s less prone to warping than ABS or Nylon, making it easier for most home 3D printers.

5. ABS and ASA

ABS has long been a standard for durable functional parts, with decent impact strength and heat resistance. ASA is a similar material but with better UV stability, making it preferable for outdoor applications.

Printing considerations: Both materials benefit from an enclosed print chamber to prevent warping and cracking. Print at 220–250°C with a heated bed (90–110°C). Use proper ventilation, as fumes can be unpleasant.

How to Choose the Best Filament for Your Needs

When selecting a filament for high-strength prints, consider:

- Mechanical loads: For maximum strength and impact resistance, Polycarbonate and Carbon Fiber-filled Nylon are top picks. For flexibility with strength, Nylon is excellent.

- Environmental conditions: Need UV and weather resistance? ASA or PETG blends are your best bet. For high-temperature applications, Polycarbonate and some Nylons excel.

- Printability: PETG and PETG blends offer a good compromise between strength and ease of printing. Polycarbonate and Nylon require more advanced printers and careful handling.

- Budget and availability: Some specialty blends and carbon fiber composites are more expensive. PETG and ABS are widely available and affordable.

Tips for Printing Stronger, More Durable Parts

- Optimize layer adhesion: Increase nozzle temperature within the recommended range for your filament, slow down print speeds, and use thicker layers (0.2mm+) where possible.

- Adjust infill and wall settings: Increase infill density and use more perimeters/walls (at least 3-4) to boost strength, especially for load-bearing parts.

- Print orientation matters: Parts are weakest along layer lines. Orient your model so that the layers run perpendicular to the primary stress direction.

- Dry your filament: Nylon and Polycarbonate are especially sensitive to moisture. Store and dry your filament as needed for the best strength and print quality.

Conclusion: Choosing the Right High-Strength Filament

For projects demanding maximum strength, Polycarbonate, Nylon, and Carbon Fiber composites are the standouts, each with unique advantages for specific applications. PETG and ASA offer practical alternatives for less demanding or outdoor-use parts. Ultimately, the best high-strength filament is the one that matches your part’s requirements and your printer’s capabilities. With the right material and print settings, you can unlock the true potential of your 3D printer for durable, functional parts ready to tackle real-world challenges.

Leave a Reply