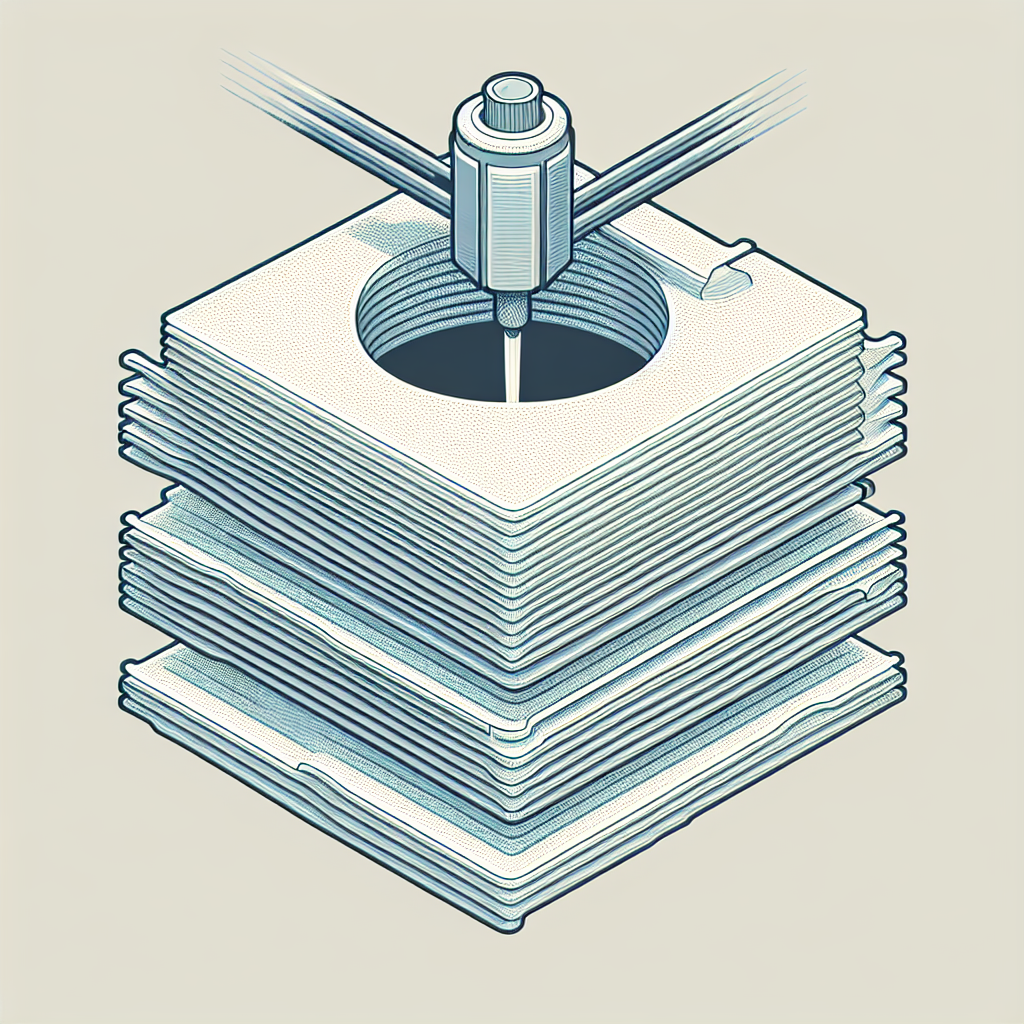

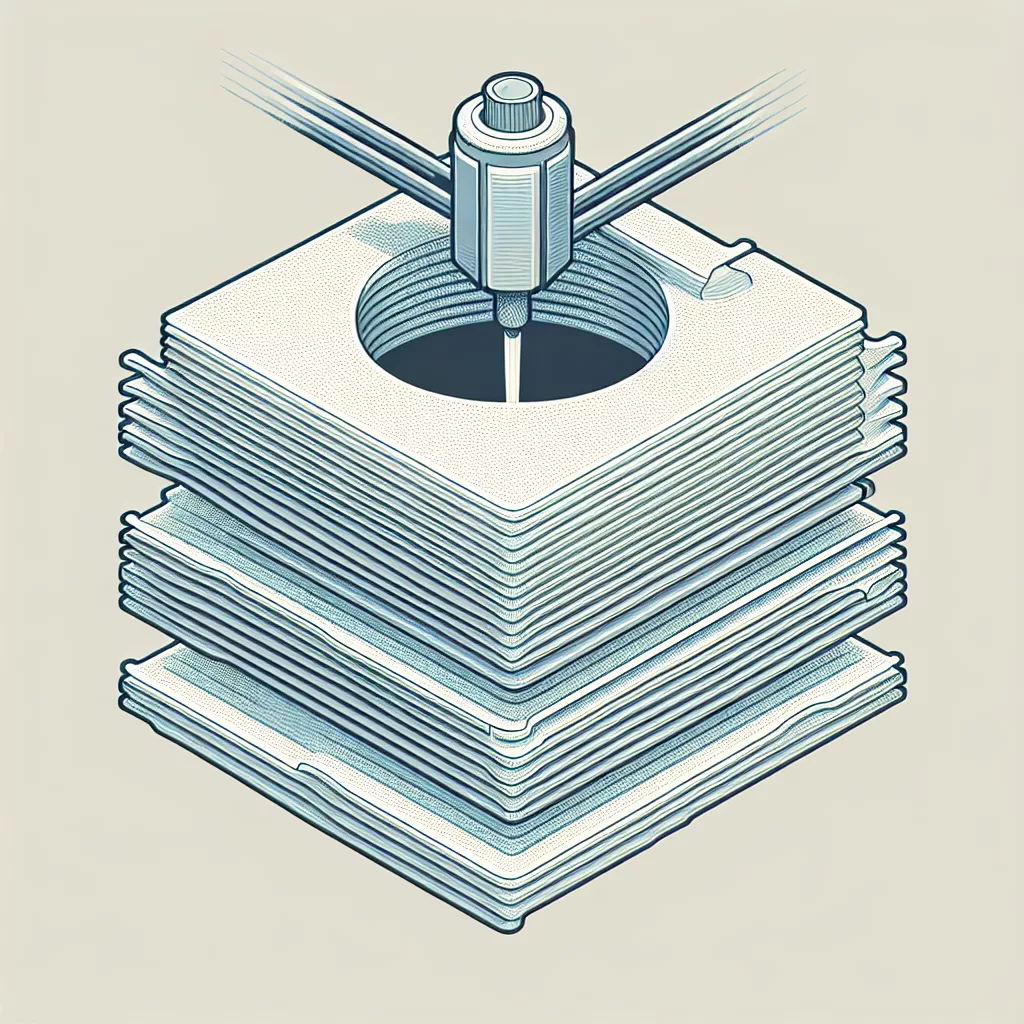

Understanding Layer Adhesion in 3D Printing

Layer adhesion is a critical factor in determining the strength and durability of 3D printed objects. It refers to how well each printed layer bonds with the one below it. Poor layer adhesion can lead to weak, brittle prints that easily delaminate or break under stress. In this article, I’ll share expert tips and insights drawn from years of hands-on 3D printing experience to help you achieve better layer bonding and consistently stronger prints.

Optimize Your Printing Temperature

Temperature plays a crucial role in layer adhesion. If the nozzle temperature is too low, the filament may not melt properly, resulting in weak bonds. Conversely, excessively high temperatures can cause stringing or sagging. Always refer to your filament manufacturer’s recommended temperature range and experiment within that window. For most materials:

- PLA: 190–220°C

- PETG: 220–250°C

- ABS: 230–260°C

Start at the lower end and increase the temperature in 5°C increments, performing simple test prints to observe layer fusion quality. Stronger adhesion is often visible as smooth, glossy layers with no signs of separation.

Adjust Your Print Speed

Printing too quickly can prevent new layers from bonding properly with the previous layer. Slower speeds allow the extruded filament to remain hot and fuse more effectively. For maximum layer strength, try reducing your speed by 25–50%. For example, if your default print speed is 60 mm/s, try 30–45 mm/s for critical parts.

Increase Extrusion Flow Rate

A slight increase in extrusion multiplier or flow rate (typically by 2–5%) can ensure that layers are slightly “squished” together, promoting better inter-layer contact. However, avoid over-extrusion, as this may lead to surface imperfections or print defects. Dial in your flow rate by calibrating your extruder and checking for under- or over-extrusion signs.

Maintain Optimal Layer Height

Layer height affects both print quality and strength. A commonly used rule of thumb is to use a layer height that is 60–80% of your nozzle diameter. For example, with a 0.4 mm nozzle, a layer height of 0.24–0.32 mm provides good strength. Thinner layers increase the number of bonds, but if set too thin, they may not adhere well due to insufficient pressure.

Use an Enclosure for Heat-Sensitive Materials

Materials like ABS and Nylon are prone to warping and poor layer adhesion if cooled too rapidly. An enclosure helps maintain a stable ambient temperature, reducing thermal stress between layers. If you don’t have a dedicated enclosure, even a simple DIY solution (cardboard box, acrylic panels) can provide significant benefits.

Ensure a Clean, Well-Calibrated Nozzle

A partially clogged or worn nozzle can result in inconsistent extrusion, leading to weak spots between layers. Regularly clean your nozzle and replace it if you notice irregular filament flow or under-extrusion, especially after printing abrasive materials.

Control Cooling Fans Strategically

While part cooling fans are crucial for print quality in materials like PLA, excessive cooling can hinder layer bonding. For stronger prints, try reducing the part cooling fan speed—especially for ABS, PETG, or when printing thicker layers. Disabling the fan for the first few layers also improves adhesion to the build plate.

Select the Right Filament

All filaments are not created equal. Higher-quality filaments generally contain fewer impurities, have more consistent diameters, and deliver stronger layer bonds. Additionally, specialty filaments like carbon fiber or glass fiber-infused materials can offer improved strength, but may require different print settings or hardened nozzles.

Consider Post-Processing Techniques

For certain materials, post-processing can further improve inter-layer adhesion. For example, acetone vapor smoothing for ABS slightly melts the outer layers, causing them to fuse and eliminate micro-gaps. Heat treating or annealing PLA in an oven can relieve internal stresses and enhance strength.

Final Thoughts

Achieving strong layer adhesion is a combination of dialing in your printer settings, maintaining your hardware, and selecting quality materials. By focusing on temperature, speed, extrusion, and environmental control, you’ll produce prints that are not only visually impressive but robust enough for functional applications. Don’t hesitate to experiment with small changes—sometimes a minor tweak can make a major difference in the strength of your 3D prints. Happy printing!

Leave a Reply