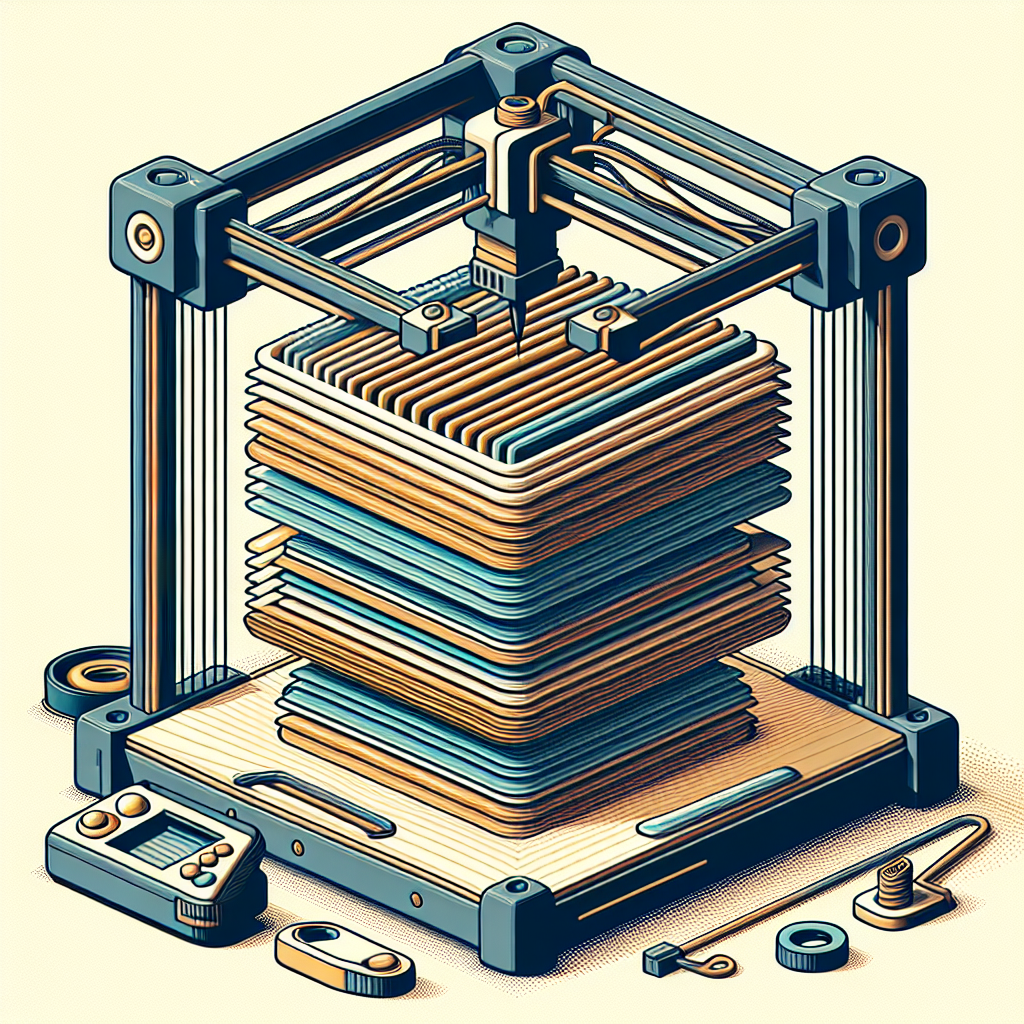

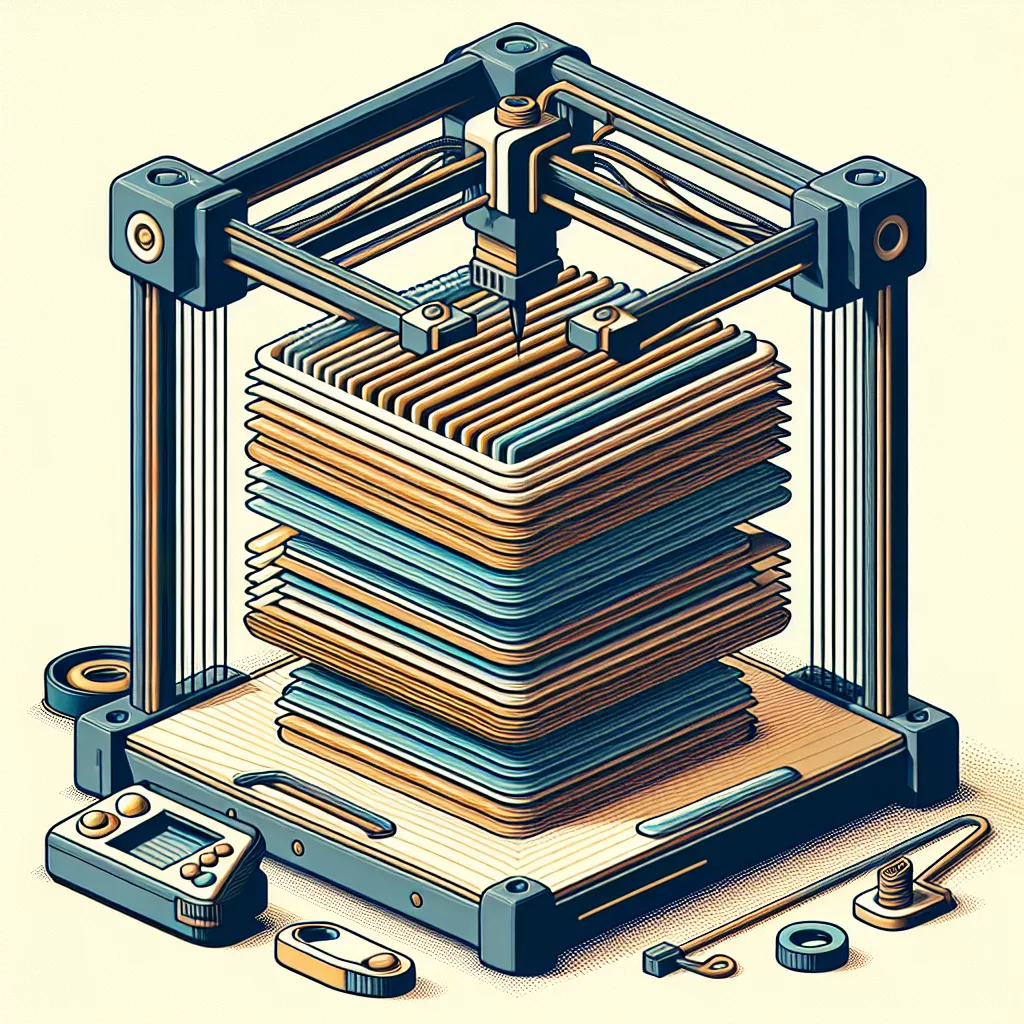

Understanding Layer Shifting in 3D Printing

Layer shifting is a common and frustrating problem for 3D printing enthusiasts and professionals alike. It occurs when the layers of a print are misaligned with each other, leading to skewed, unusable, or even completely failed prints. If you’ve noticed your prints have unexpected steps, jagged edges, or appear “slid” partway through, you’re facing layer shifting. Let’s break down why it happens and how you can fix it.

Common Causes of Layer Shifting

Before jumping into solutions, understanding the root causes of layer shifting is essential. Typically, it’s due to mechanical or electronic issues:

- Loose belts or pulleys: If your printer’s belts or pulleys are not tight, the movement in the X or Y axis can slip, causing layer misalignment.

- Obstructions: Objects or filament tangles can block the print head or bed, resulting in skipped steps.

- Stepper motor issues: Overheating or insufficient current to the stepper motors can cause them to skip steps.

- High print speeds: Printing too quickly can overwhelm your printer’s mechanical components, especially on less robust machines.

- Firmware or G-code errors: Faulty instructions can prompt your printer to move incorrectly.

Step-By-Step Solutions for Fixing Layer Shifting

1. Check Belt Tension and Pulleys

The most common culprit is loose or worn belts and pulleys. Inspect your printer’s X and Y axis belts. They should be taut but not overly tight—like the string of a guitar. Give them a gentle pluck; a slack belt will flutter, while a correctly tensioned one should have a bit of resistance.

Also, check the pulleys attached to your stepper motors. Make sure the grub screws are securely fastened to the motor shaft. If pulleys slip, the axis may not move as commanded, leading to shifts.

2. Eliminate Obstructions

Carefully examine the printer for any obstructions in the path of the print head or bed. Loose wires, curled filament, or even a blob of plastic on the rails can cause collisions and skipped steps. Keep your build area clean and make sure nothing interferes with movement.

3. Adjust Stepper Motor Current

Stepper motors require a specific current to function correctly. Too little current causes weak movement and skipped steps; too much can cause overheating and shutdowns. On most open-frame 3D printers, you can adjust the current using the potentiometer on the stepper driver or through firmware (on some machines). Consult your printer’s documentation for guidance, and adjust in small increments.

4. Slow Down Your Print Speed

If you’ve recently increased your print speed, try lowering it back to the manufacturer’s recommended settings. Excessive acceleration and jerk settings can also cause missed steps. Most slicing software allows you to adjust these parameters. Start with conservative values and increase as you gain confidence in your printer’s mechanical robustness.

5. Lubricate and Maintain Rails and Bearings

Bind or drag on the axis can cause motors to skip steps. Regularly clean and lubricate linear rails, rods, and bearings using appropriate lubricants. This ensures smooth motion and reduces the load on your stepper motors.

6. Review Your G-code and Firmware

Software-related errors, though less common, can cause layer shifting. Double-check your slicer settings and consider re-slicing your model. Make sure your firmware is up-to-date and correctly configured for your specific hardware.

7. Inspect the Stepper Motor and Driver Health

A failing stepper motor or stepper driver can intermittently skip steps. If you suspect an electrical issue, swap the motor or driver with another axis to see if the problem follows the component. Replace any faulty parts as needed.

Preventing Future Layer Shifts

– Regularly maintain your printer: Tighten belts, check pulleys, clean rails, and lubricate moving parts.

– Don’t overload your printer: Stick to recommended print speeds unless you’ve upgraded components for high-speed printing.

– Monitor the first few layers: Early detection of issues can save filament and time.

– Check your workspace: Vibrations or jostling of the printer can cause shifts, especially on unstable surfaces.

Conclusion

Layer shifting is preventable with routine maintenance and careful attention to your printer’s mechanics and settings. By addressing the common causes and following these troubleshooting steps from my years of experience, you’ll enjoy more reliable, high-quality 3D prints. Remember, a well-maintained printer is the foundation for successful projects!

Leave a Reply