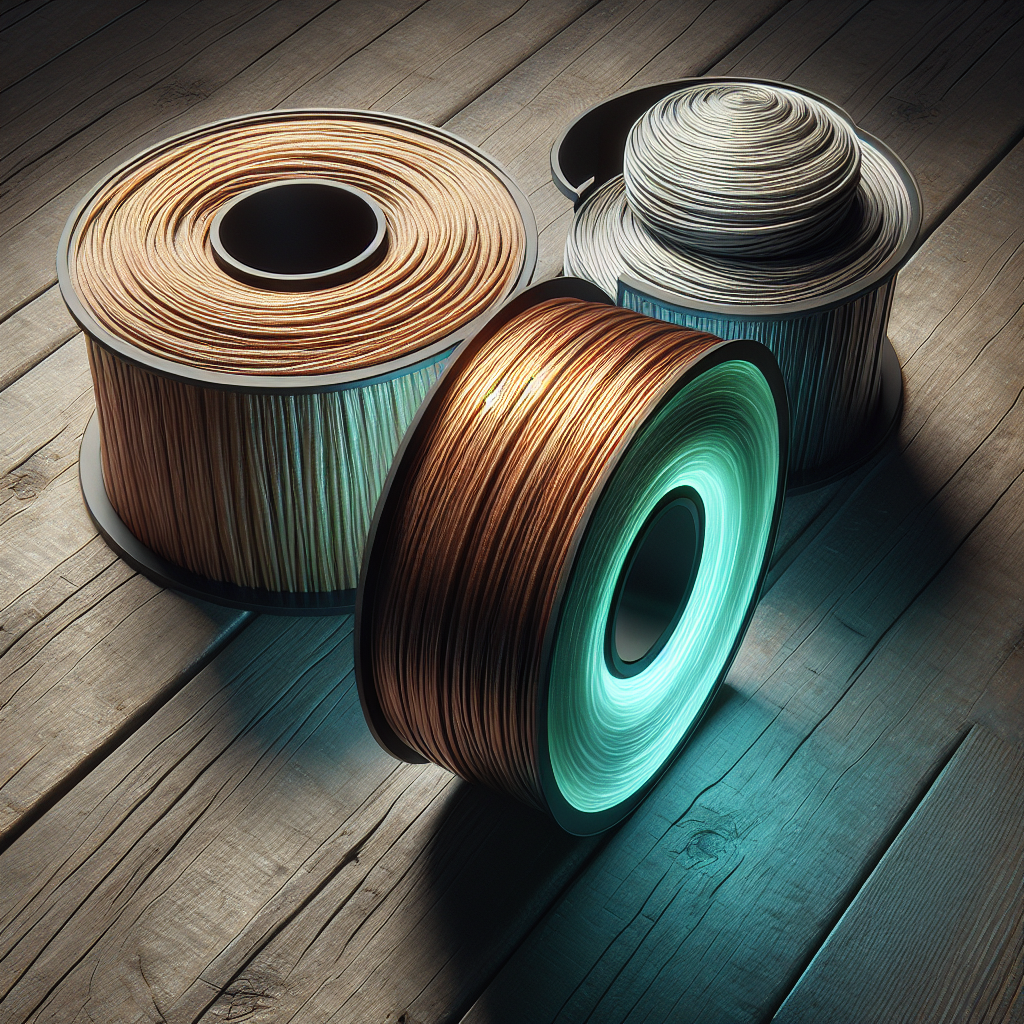

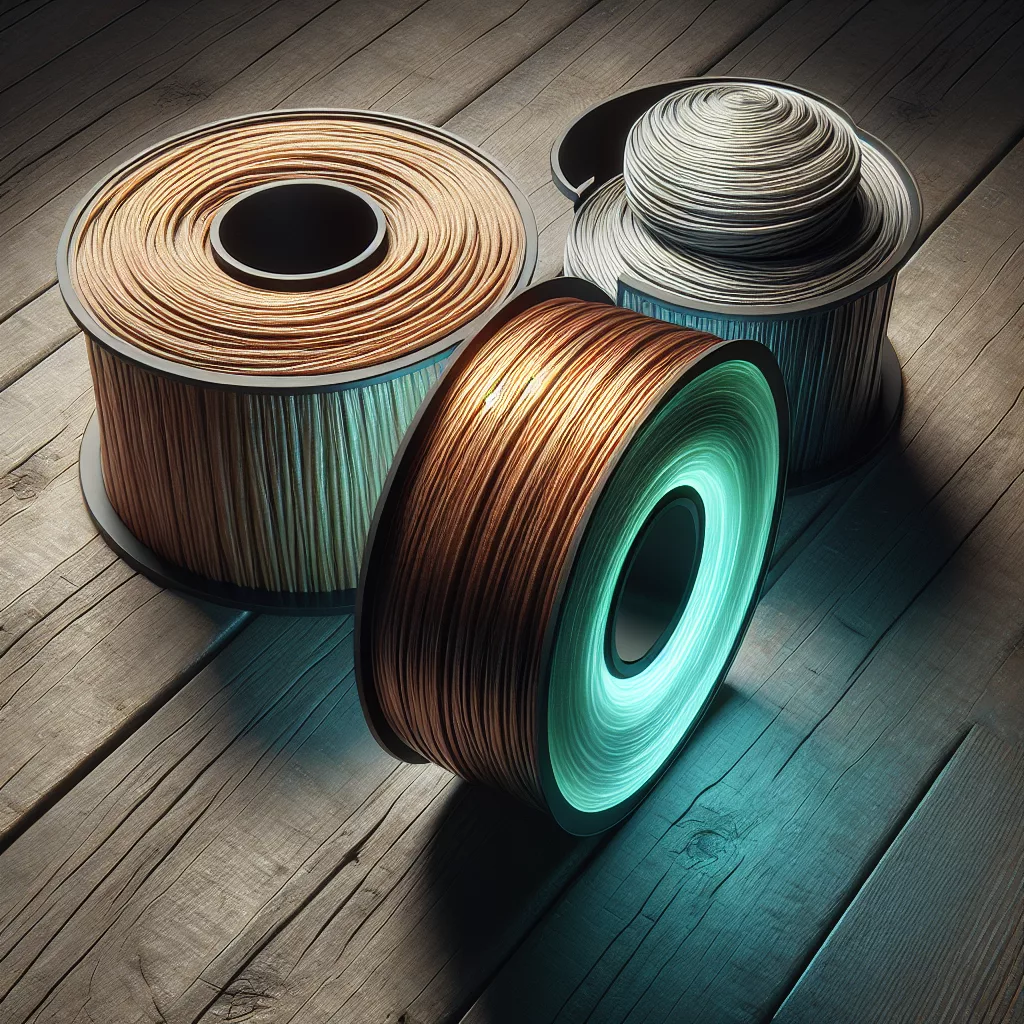

Introduction to Specialty Filaments: Elevate Your 3D Printing

Stepping into the world of specialty filaments can dramatically enhance your 3D printing experience. Wood, metal, and glow-in-the-dark filaments offer unique aesthetic and functional properties that standard PLA or ABS simply can’t match. In this guide, we’ll explore how to successfully print with these specialty filaments, ensuring excellent results every time.

Wood Filament: Bring Nature into Your Prints

Wood filament typically combines PLA with fine wood particles, creating prints that not only look like wood but can also be sanded, stained, and polished just like natural timber.

Tips for Printing with Wood Filament:

- Nozzle Temperature: Start with a temperature between 190°C and 220°C. Lower temperatures usually result in lighter, more natural-looking wood tones, while higher temperatures make the print darker.

- Nozzle Size: Use a larger nozzle (0.5mm or greater) to avoid clogging, as wood fibers can be prone to blockage.

- Retraction and Print Speed: Limit retraction and print slowly (40-60 mm/s) to reduce the risk of filament jams and provide a smooth finish.

- Post-processing: Sand your prints with fine-grit sandpaper to bring out a realistic wood grain appearance. Applying wood stain or varnish afterward is also possible.

Common Challenges and Solutions:

- Clogging: If clogs occur, consider using a cleaning filament regularly or upgrading to a hardened steel or brass nozzle.

- Inconsistent Texture: Ensure consistent extrusion flow by regularly calibrating your extruder and filament diameter settings.

Metal Filament: Achieve a Metallic Look

Metal-infused filaments offer the visual appeal and weighty feel of metal items. These filaments typically blend PLA or ABS plastic with small metal particles such as copper, bronze, brass, or stainless steel.

Tips for Printing with Metal Filament:

- Printer Setup: Use a wear-resistant nozzle (hardened steel or ruby tip). Standard brass nozzles wear quickly due to metal particles.

- Nozzle Temperature: Metal filaments usually require slightly higher temperatures, typically between 200°C and 230°C, depending on the brand and type of metal.

- Print Speed: Slow and steady wins the race—stick to around 30-50 mm/s to reduce jams and ensure high-quality output.

- Cooling: Use minimal cooling fan settings to prevent layer separation but avoid excessive cooling that might compromise layer adhesion.

- Post-processing: Sanding, polishing, and even oxidizing (for copper or bronze filaments) can greatly enhance the print’s metallic appearance and realism.

Common Challenges and Solutions:

- Excessive Nozzle Wear: Upgrade to a hardened steel nozzle to maintain consistent print quality and durability.

- Poor Layer Adhesion: Slightly increasing bed temperature or applying adhesive surfaces (e.g., glue stick or build sheet) can improve print stability.

Glow-in-the-Dark Filament: Illuminate Your Creations

Glow-in-the-dark filaments contain phosphorescent material that absorbs natural and artificial light, glowing brightly in dark environments. These filaments are ideal for creative and decorative prints, toys, and signage.

Tips for Printing with Glow-in-the-Dark Filament:

- Nozzle and Bed Temperatures: Aim for a nozzle temperature around 200°C–220°C and a heated bed temperature of around 50°C–60°C.

- Nozzle Wear: Glow-in-the-dark filaments are abrasive. Use a hardened steel or ruby nozzle to avoid excessive nozzle wear.

- Layer Height and Speed: Use slightly thicker layers (0.2mm–0.3mm) and moderate print speeds (around 50 mm/s) to achieve consistent layers and better filament flow.

- Charge the Glow: Before displaying your print in the dark, expose it to bright natural sunlight or strong artificial lighting to maximize its glow intensity and duration.

Common Challenges and Solutions:

- Weak Glow Effect: Increase wall thickness or infill for more glowing material. Longer exposure to bright sources of light helps achieve a stronger glow.

- Nozzle Clogging: Regular cleaning and using a dedicated nozzle for abrasive filaments will help maintain consistent printing results.

Final Thoughts: Experiment and Elevate Your Prints

Wood, metal, and glow-in-the-dark filaments offer exciting possibilities to elevate the quality and appeal of your 3D-printed creations. With proper printer settings, careful tuning, and thoughtful post-processing, you can achieve amazing results. Embrace the challenge and start experimenting with these specialty filaments to expand your 3D printing horizons.

Leave a Reply