Introduction

As 3D printing becomes increasingly prevalent across industries, the demand for stronger and more resilient parts continues to rise. Many makers and engineers often assume that strengthening 3D printed parts involves redesigning the part itself. However, there are several effective strategies for significantly improving part strength without modifying your original design. In this article, we will explore various techniques and best practices you can use to easily achieve stronger 3D prints.

Optimize Printing Orientation

The orientation of your print on the print bed directly impacts the mechanical properties of the finished product. While the design may remain unchanged, simply rotating your model can dramatically increase structural integrity. Consider the stresses and forces your part will face during its application. For instance, orienting layers perpendicular to the direction of stress can help avoid delamination and layer separation. Taking a moment to carefully consider orientation is one of the simplest and most effective methods to strengthen your 3D printed parts without any design adjustments.

Adjust Layer Height and Line Width

Layer height and extrusion width can heavily influence your part’s mechanical strength. Reducing your layer height will increase the number of layers, effectively enhancing interlayer adhesion and reducing the appearance of visible layer lines. Similarly, increasing your extrusion width slightly will result in stronger layers, better bonding, and reduced likelihood of layer separation. While these changes may slightly affect your overall printing time, the resulting strength improvements are well worth the extra effort.

Increase Wall Thickness and Shell Count

One of the easiest ways to improve strength without modifying your original 3D model is by adjusting your slicer’s settings to increase the wall thickness and shell count (also known as perimeters). Thicker outer shells distribute stress more evenly throughout the part, significantly increasing durability. Even a small increase in wall thickness can dramatically reduce the likelihood of cracks, fractures, and breaks during use.

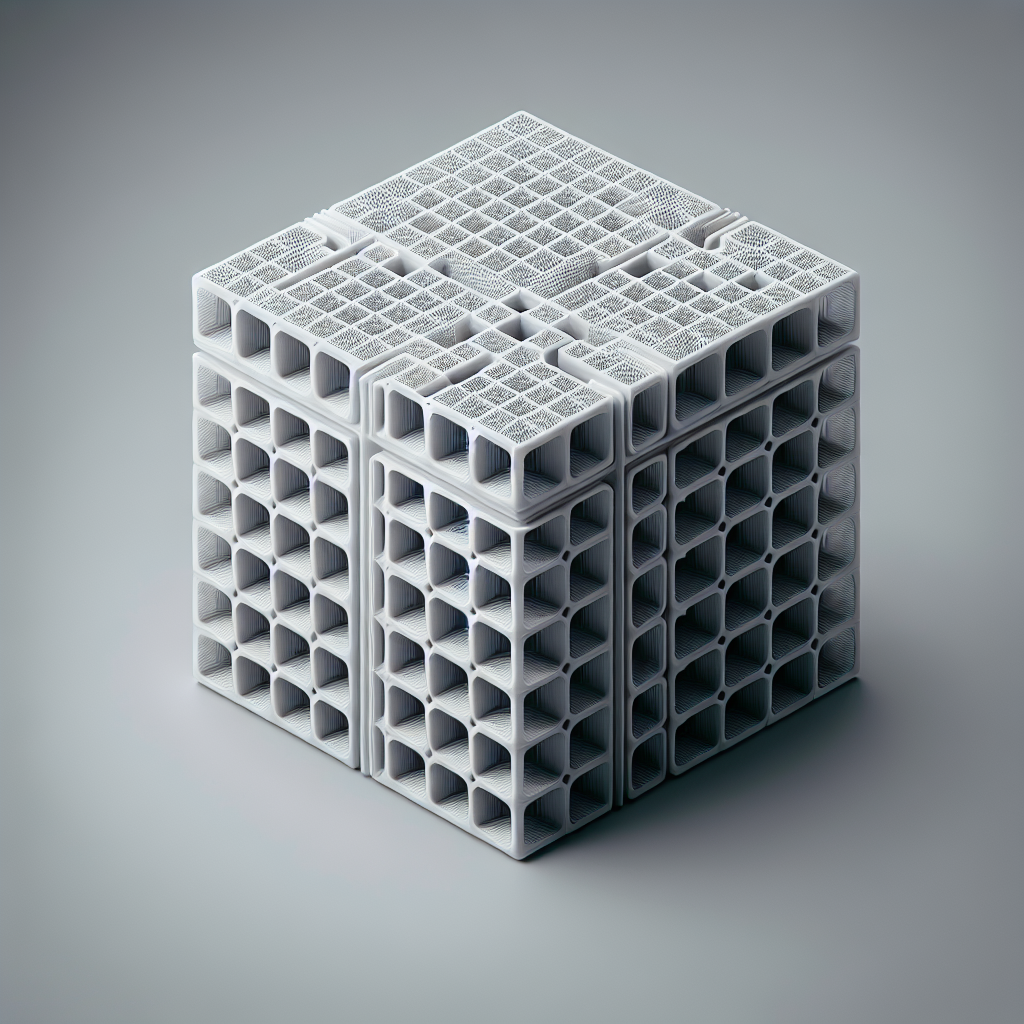

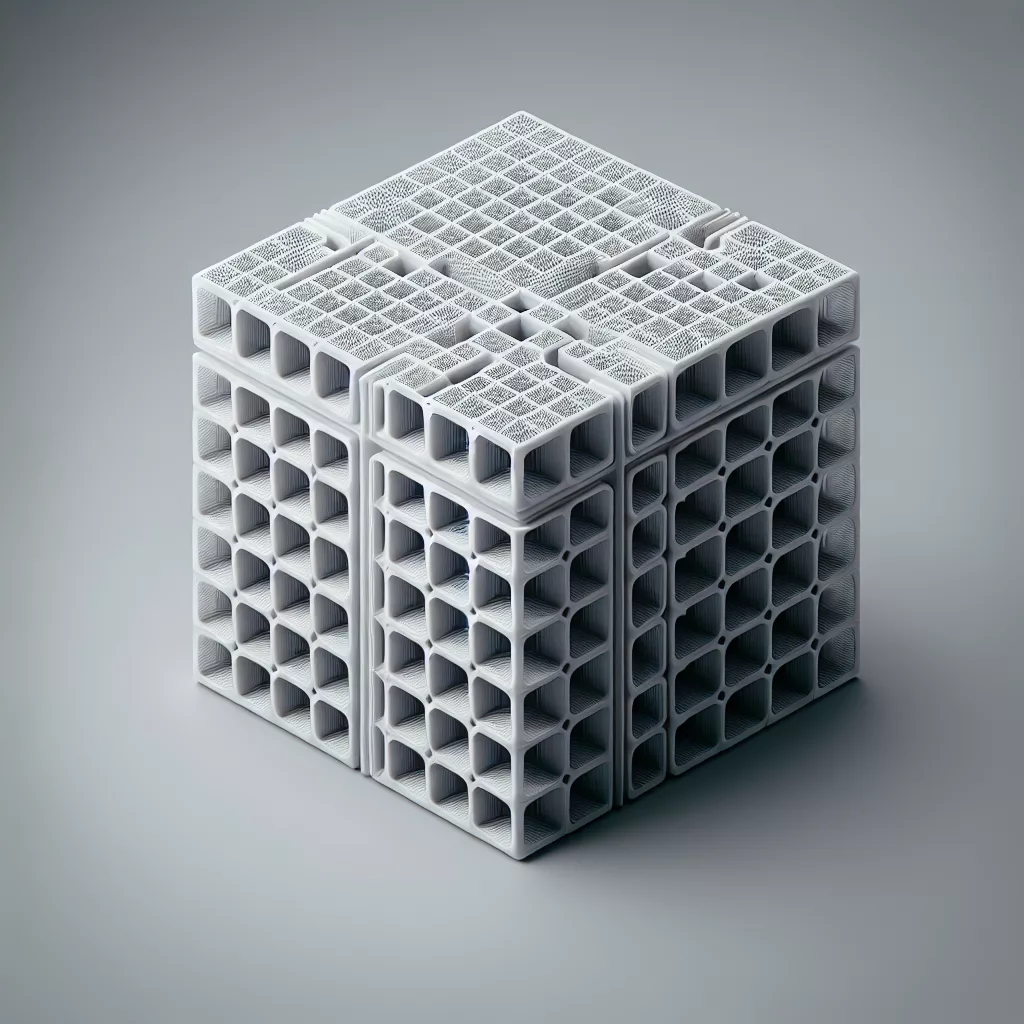

Increase Infill Density or Change Infill Pattern

The internal structure of your print—its infill—is critical to determining overall strength. A higher infill density naturally increases strength, rigidity, and durability. Even a small increase in infill percentage can make a noticeable difference in part stability.

Additionally, choosing the right infill pattern can significantly enhance mechanical properties. Patterns such as honeycomb, gyroid, or cubic infill, provide better strength-to-weight ratios and can help evenly distribute stress within your part, resulting in increased resistance to mechanical failure.

Control Print Speeds and Temperatures

3D printer settings, such as print speed and temperature, have a major impact on the final part strength. Slower print speeds create better adhesion between layers, resulting in stronger and more reliable parts. Likewise, optimizing your nozzle and bed temperatures based on filament manufacturer recommendations can greatly enhance mechanical properties and layer adhesion. Consider experimenting with slightly higher nozzle temperatures—within recommended limits—to ensure maximum layer bonding.

Utilize Appropriate Cooling Settings

Cooling, or the controlled lack thereof, can directly affect part strength. For materials like PLA, moderate cooling helps retain shape accuracy without sacrificing strength. However, materials such as ABS, PETG, or Nylon generally require minimal or no cooling fan support to achieve maximum interlayer bonding. Carefully review your cooling settings according to your filament type and reduce cooling fan speeds when printing with advanced engineering filaments to increase overall strength.

Post-Processing Techniques for Added Strength

Several post-processing procedures can amplify part strength without modifying your original design:

- Annealing: Heating the printed part and slowly cooling it can significantly strengthen and toughen your prints.

- Epoxy Coating: Applying thin layers of epoxy resin to the exterior of your print adds rigidity and durability.

- Vapor Smoothing: When using filaments such as ABS, acetone vapor smoothing can fuse outer layers and significantly improve structural integrity.

Conclusion

Achieving stronger 3D printed parts doesn’t always require complicated design revisions. By focusing on optimized printing orientations, adjusting your slicer settings, fine-tuning temperatures and speeds, and employing post-processing techniques, you can significantly enhance the mechanical strength of your 3D prints. Implementing these simple best practices can result in reliable, durable, and robust parts, helping you achieve your project goals effectively and efficiently.

Leave a Reply