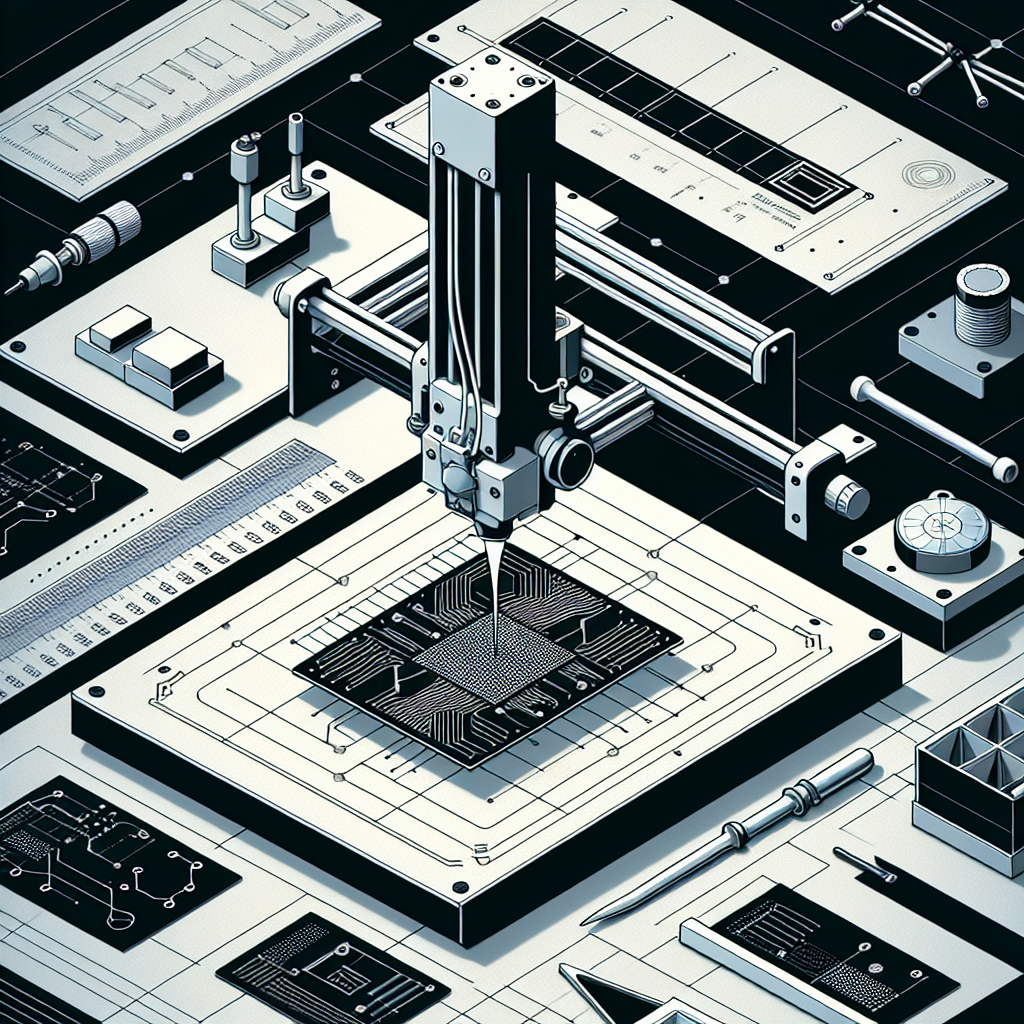

Introduction to 3D Printing Electronics

The rapidly evolving field of 3D printing, also known as additive manufacturing, has revolutionized various sectors—from healthcare to aerospace, automotive, and beyond. Traditionally, 3D printing focused mainly on creating mechanical structures or prototypes using plastics, metals, and resins. However, recent technological advances have brought electronics into the sphere of additive manufacturing, allowing innovators and hobbyists alike to print functional electronic components and even circuit boards. But how practical is it, and can you realistically print circuit boards at home or professionally?

Understanding How Electronics Are Printed

When discussing 3D printing electronics, we refer to processes capable of integrating conductive materials directly within the printed structure. Typically, conventional printed circuit boards (PCBs) are fabricated through subtractive manufacturing techniques—such as chemical etching—where material is removed from copper-clad boards to create conductive paths. On the other hand, additive manufacturing involves directly depositing conductive materials in specific patterns, layer by layer, to construct functioning circuits embedded within a 3D structure.

There are several existing methods for 3D printing electronics:

- Conductive Ink Extrusion: Specially formulated conductive inks, usually comprising silver, copper, or graphene particles, are extruded through specialized print heads.

- Aerosol Jet Printing: Conductive inks are atomized into a dense aerosol mist deposited onto various substrates to form conductive pathways.

- Multi-material FDM (Fused Deposition Modeling): Combining insulating thermoplastic filaments with conductive composite filaments designed for electronic functionality.

Can You Actually 3D Print Circuit Boards?

Yes, you can. However, it’s essential to understand that the capability and practicality of 3D printing circuit boards depend greatly on the complexity and application of the electronics you require. For simple circuits, sensors, prototypes, and educational projects, current 3D printed electronics technology is increasingly accessible and practical.

The primary advantages of 3D printing circuit boards include rapid prototyping, customization, and the potential to seamlessly embed electronics in complex geometries—something traditional flat PCBs cannot achieve easily. On the other hand, the technology is not yet mature enough to entirely replace traditional PCB manufacturing methods, especially for high-density circuits, precision, and mass-production scenarios.

Advantages of 3D Printed Circuit Boards

- Rapid Prototyping: Quickly test ideas and iterate designs without delays associated with traditional PCB fabrication processes.

- Complex Geometries: Embed circuitry into unique shapes and structures, offering flexibility for designers and engineers.

- Reduced Manufacturing Waste: Additive manufacturing is inherently more sustainable as it only uses the material required, minimizing waste compared to traditional subtractive PCB methods.

- Customization: Easily tailor circuits to specific projects and designs without the high setup costs or delays typical of conventional manufacturing.

Limitations and Challenges

- Conductivity and Performance: Printed conductive inks typically exhibit higher resistance levels than traditional PCB copper traces, potentially limiting current-carrying capabilities and overall circuit performance.

- Resolution and Complexity: Achieving fine trace widths and spacing comparable to traditional PCBs is challenging with current 3D printing technologies.

- Durability and Stability: Conductive inks can be less stable and less resilient to environmental factors like moisture, oxidation, or mechanical stress compared to traditional copper conductors.

- Cost: High-quality conductive inks and specialized printing equipment can be costly, potentially limiting accessibility, especially for hobbyists.

Applications of 3D Printed Electronics

Despite current limitations, the potential and applications for 3D printed electronics are expanding rapidly:

- Wearable Electronics: Flexible sensors and circuits integrated directly into fabric or personalized wearable devices.

- Robotics: Custom-shaped sensors, actuators, and integrated electronics tailored to complex robotic geometries.

- Education and Prototyping: Quick-turnaround, hands-on learning opportunities and experimental prototypes at schools, colleges, or makerspaces.

- Medical Devices: Highly customized electronics embedded into prosthetics, hearing aids, and personalized medical equipment.

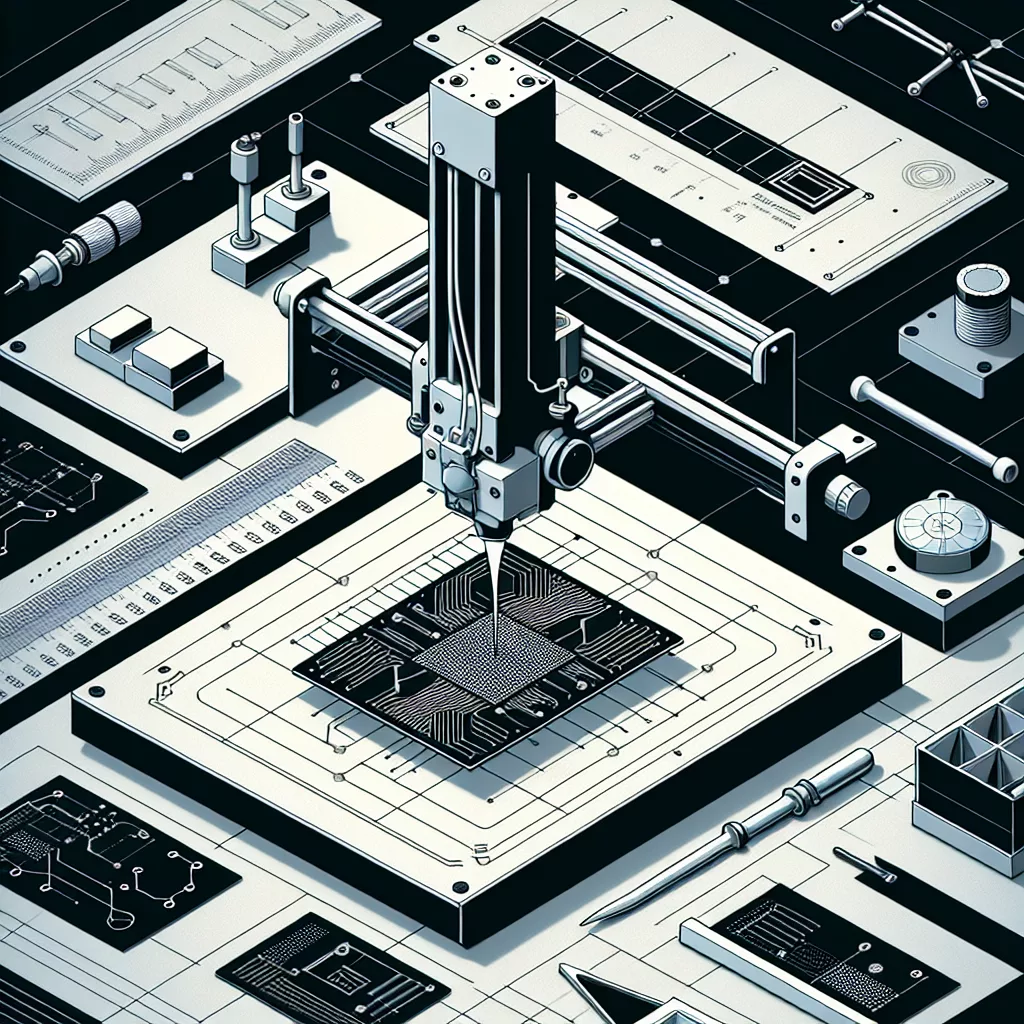

What You Need to Get Started

If you’re interested in experimenting with 3D printed circuit boards, here are some basic steps and resources you’ll need:

- A Specialized 3D Printer: Machines capable of dual or multi-material extrusion, or specifically designed 3D printers for electronics such as the Voltera V-One or Nano Dimension DragonFly.

- Conductive Filaments or Inks: Conductive PLA filaments, silver nanoparticle inks, or graphene composites specifically developed for electronics.

- Design Software: CAD software that supports multi-material designs and conductive path layouts—Fusion 360, SolidWorks, or specialized electronic CAD programs.

- Testing Equipment: Multimeters, oscilloscopes, and other electronic instrumentation for assessing and verifying your printed circuits.

The Future of 3D Printed Electronics

As the technology matures, we can anticipate significant improvements in conductivity, resolution, and durability of printed electronics. Advanced materials—such as graphene-infused inks and composite conductive filaments—will likely close performance gaps between traditionally fabricated PCBs and additive manufactured circuits. Additionally, as costs continue to decrease and accessibility improves, more hobbyists, educators, and small businesses will embrace this powerful technology.

Conclusion

While not yet a complete replacement for traditional PCB manufacturing, the current capabilities of 3D printed electronics already offer exciting possibilities. For prototyping, embedded electronics in complex structures, educational projects, and highly customized solutions, 3D printed circuit boards present unique advantages. As the field evolves, we can expect 3D printing to become an increasingly viable option for an even wider range of electronic applications.

Leave a Reply